11 SERVICE WORK ON THE CHASSIS

58

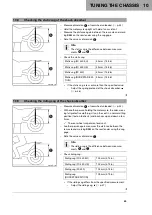

11.12

Installing the fork legs

H01182-10

Main work

–

Position the fork legs.

Air bleeder screw

1

of the right fork leg is positioned to

the front.

Valve

A

of the left fork leg faces the front.

Info

Grooves are milled into the side of the upper end of

the fork legs. The second milled groove (from the top)

must be flush with the upper edge of the upper triple

clamp.

The air suspension is located in the left fork leg. The

pressure and rebound damping is located in the right

fork leg.

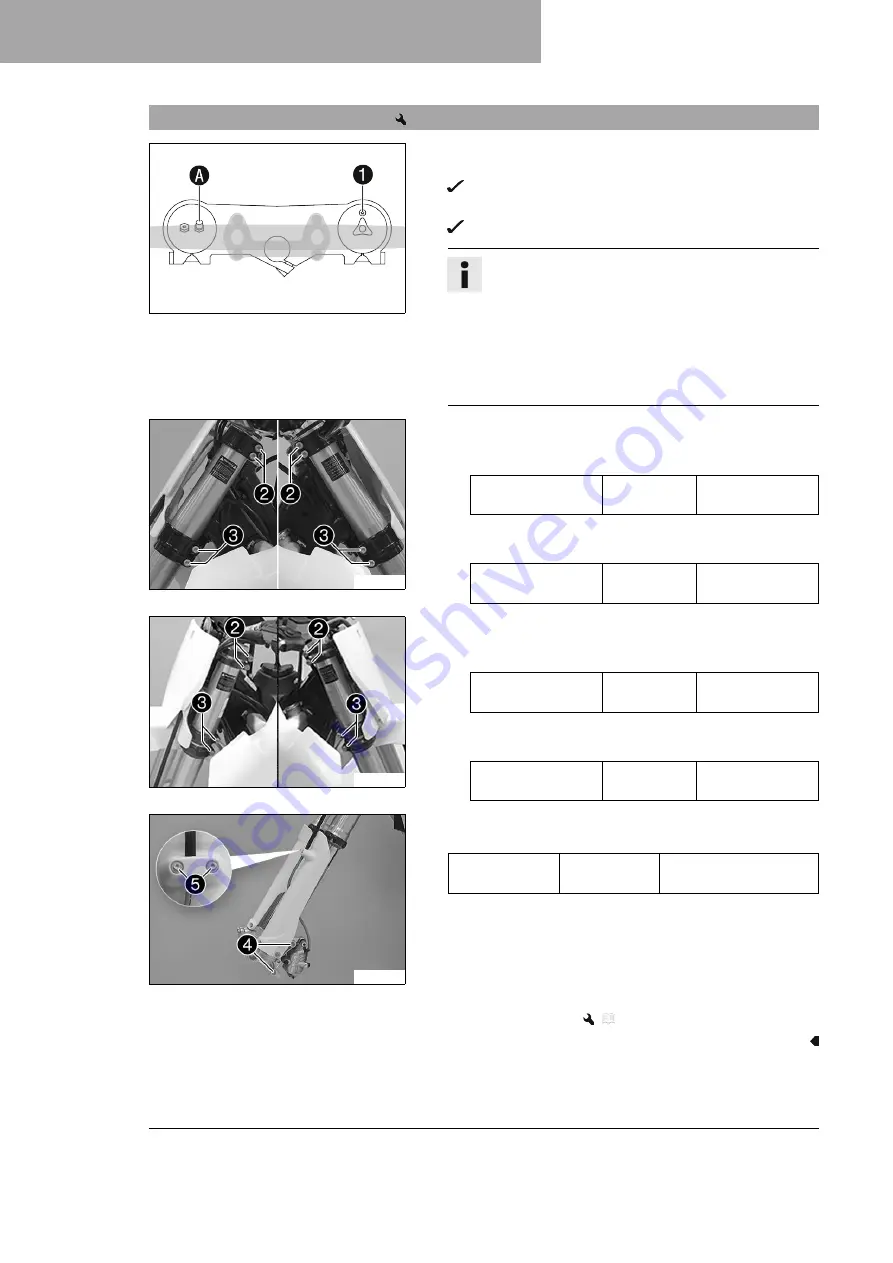

S02314-11

(All models apart from special models)

–

Tighten screws

2

.

Guideline

Screw, top triple

clamp

M8

17 Nm (12.5 lbf ft)

–

Tighten screws

3

.

Guideline

Screw, bottom

triple clamp

M8

12 Nm (8.9 lbf ft)

A00506-11

(ROCKSTAR EDITION)

–

Tighten screws

2

.

Guideline

Screw, top triple

clamp

M8

17 Nm (12.5 lbf ft)

–

Tighten screws

3

.

Guideline

Screw, bottom

triple clamp

M8

12 Nm (8.9 lbf ft)

S02315-11

–

Position the brake caliper. Mount and tighten screws

4

.

Guideline

Screw, front

brake caliper

M8

25 Nm (18.4 lbf ft)

Loctite

®

243™

–

Position the brake line and the clamp. Mount and tighten

screws

5

.

Finishing work

–

Install the front wheel.