a) Push the middle of the first drive belt.

b) If the top side of the first belt is level with the

lower side of the second drive belt, the tension is

correct.

c) If the top side of the first drive belt is below the

lower side of the second drive belt, the tension is

To increase the tension of the

.

d) If the top side of the first drive belt is above the

lower side of the second belt, the tension is too

high. Refer to

To increase the tension of the

.

6. Examine the drive belts for wear and damages.

Replace damaged drive belts.

CAUTION:

Do not replace only 1 of

the drive belts. Always replace all drive

belts at the same time.

7. Install the protective cover, the bolts, the washers

and the nuts.

To increase the tension of the drive belt

CAUTION:

The tension of the new drive

belt must be increased after the first 2–4

hours of operation.

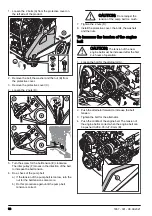

1. Loosen the locknut (A) and then turn the nut (B) for

the belt tension. Turn the nut for belt tension

counterclockwise (C) to decrease the drive belt

tension. Turn the nut for belt tension clockwise (D) to

increase the drive belt tension.

B

A

D

C

2. Do a check of the drive belt.

a) If the tension of the drive belt is too low, turn the

nut for the belt tension some more.

b) Do this procedure again until the drive belt

tension is correct.

CAUTION:

Do not adjust the

tension of the drive belt too much.

3. Hold the nut for belt tension tightly and at the same

time tighten the locknut.

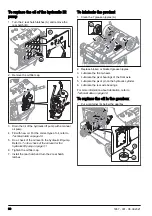

To increase the tension of the pump

belt for the hydraulic propulsion system

CAUTION:

The tension of the new

pump belt must be increased after the first

2–4 hours of operation.

1657 - 001 - 08.09.2021

35

Summary of Contents for FS 4600 G II

Page 165: ...1657 001 08 09 2021 165 ...

Page 166: ...166 1657 001 08 09 2021 ...

Page 167: ...1657 001 08 09 2021 167 ...