48

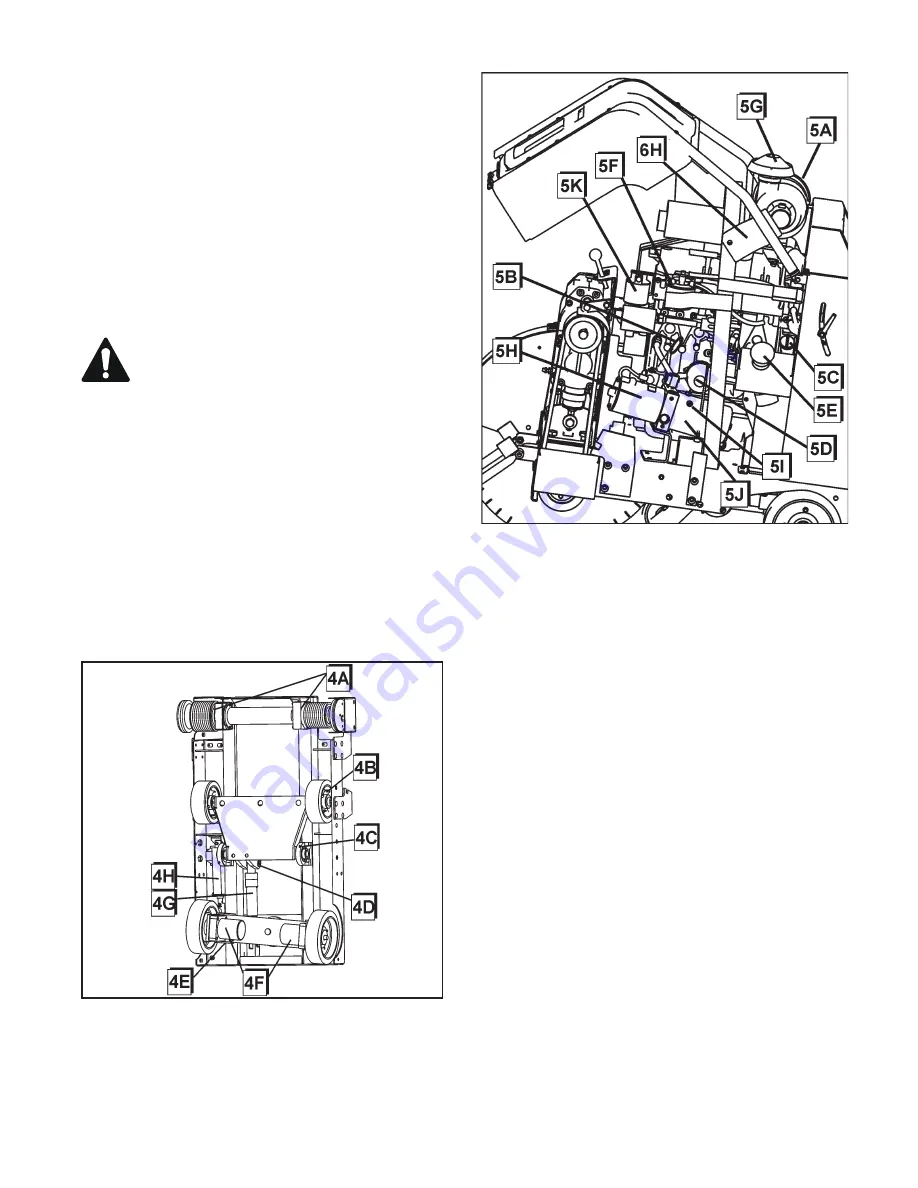

FIGURE 4

4A. BLADESHAFT BEARING SEALS

4B. FRONT WHEEL BEARINGS

4C. FRONT AXLE PIVOT BEARINGS

4D. HYDRAULIC CYLINDER PIVOT PIN

4E. REAR AXLE

4F. HYDRAULIC WHEEL MOTOR

4G. RAISE LOWER CYLINDER

4H. LINEAR ACTUATOR

FIGURE 5

5A. AIR FILTER ASSEMBLY:

Includes

a) Housing

b) Cover

c) Primary Outer Element:

Clean or replace when

AIR RESTRICTION INDICATOR (1N) shows the

RED warning.

d) Inner Safety Element:

DO NOT CLEAN this

filter element. Replace 1 time per year or if it

becomes damaged.

5B. ENGINE OIL DIPSTICk:

Check Engine Oil Level

Here. Dipstick indicates oil level. See engine opera-

tion manual for more information.

5C. ENGINE OIL FILL:

Fill engine with recommended

oil at this location. Use SAE 15W40 API Class CF,

CF-4, CG-4, or CI-4 engine oil. See engine

operation manual for more information.

5D. ENGINE OIL FILTER:

See engine operation

manual for more information.

5E. FUEL TANk FILL:

Fill the fuel tank at this location.

5F. FUEL FILTER:

5G. AIR FILTER RAIN CAP

5H. D.C. (direct current) LIFT PUMP:

Raises and

lowers the saw.

5I. HYDRAULIC RESERVOIR FILL:

Fill and check

hydraulic system fluid here.

5J. HYDRAULIC OIL RESERVOIR:

1.5 Quart Capacity

(1.42 Liter)

5k. HYDRAULIC FILTER:

Filters hydraulic

system fluid.

5L. ----

3-2M. V-BELTS: Set of 4, 3 Groove

3-2N. GEARBOX PULLEY:

3-2O. GEARBOX SHIFT LEVER:

Use to change output

speed of the ENGINE GEARBOX (3-2A). Three-

Speeds and two Neutral positions are available.

GEARBOX SHIFT LEVER positions (1, 2, and 3)

are color coded to match, among others, Gearbox

Range / Blade RPM decal. GEARBOX SHIFT

LEVER Operation:

1) Turn ENGINE START SWITCH (1H) to OFF

(“0”) position. Always turn Engine OFF before

shifting gearbox!

2) Verify that pulley size, flange size, and

blade shaft speed are correct for the blade

size being mounted.

WARNING: Serious injury can occur to the

operator or people in the work area if the

rotational speed (n/min) of the DIAMOND

BLADE (2E) exceeds the maximum speed (n/

min) marked on the DIAMOND BLADE (2E).

3) Lift GEARBOX DETENT KNOB (3-2P) and twist

to hold in “OPEN” position.

4) Move GEARBOX SHIFT LEVER (3-2O) to

required gear. A slight “rocking motion” of the

gearbox output shaft (or BLADE SHAFT) may

improve shifting.

5) Twist and lower GEARBOX DETENT KNOB

(3-2P) back to original “LOCKED” position.

3-2P. GEARBOX DETENT kNOB:

Locks GEARBOX

SHIFT LEVER (3-2O) in position. See GEARBOX

SHIFT LEVER (3-2O) for operation.

Summary of Contents for FS 4800 D

Page 7: ... NOTES NOTAS REMARQUE ...

Page 31: ...31 NOTES NOTAS REMARQUE ...

Page 37: ...37 FS 4800 D DIESEL SPECIFICATIONS Standard CE Models ...

Page 39: ...39 ESPECIFICACIONES DE DIESEL FS 4800 D Modelos estándar y CE ...

Page 41: ...41 SPÉCIFICATIONS DU FS 4800 D DIESEL Modèles standards et CE ...

Page 112: ...542 20 10 97 2006 44 ...