55

• Adjustments can be made while sawing or not sawing.

• Visually confirm the axle movement and direction.

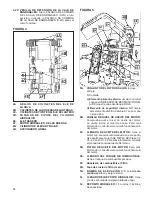

Standard Model

Saw with Manual Axle Adjustment

• The axle (4E) is adjusted by turning the M12 MANUAL

AXLE ADJUSTMENT BOLT (1CC) located at the rear

lower left of saw frame.

• If the saw steers to the RIGHT while sawing, turn

the MANUAL AXLE ADJUSTMENT BOLT (1CC)

COUNTERCLOCKWISE.

• If the saw steers to the LEFT while sawing,

turn the MANUAL AXLE ADJUSTMENT BOLT

(1CC) CLOCKWISE.

Rear Pivot Model

(Saw with Differential Pivot option):

• Simply bear against the HANDLEBARS (6G) to hold the

saw on the cutting line. DO NOT shift the DIFFERENTIAL

SWITCH (1J) from the Center “Lock” position. The Left,

“Pivot”, position of the DIFFERENTIAL SWITCH (1J) is

NOT for adjusting the straight line sawing of the saw.

10

Maintenance

(See Figures 1-6)

Before performing any maintenance, ALWAYS

park the machine on a level surface with the

Engine OFF and the ENGINE START SWITCH

(1H) in the “0” (OFF) position.

After each use CLEAN the machine.

LUBRICATION:

ENGINE OIL:

Check daily (5B). Change Engine Oil and

ENGINE OIL FILTER (5D) after every 100 HOURS of

operation. See engine manual for recommended oil. SAE

15W40 API Class CF, CF-4, CG-4, or CI-4 engine oil is

generally recommended. Capacity is 7.8 quarts (7.4 liters)

with ENGINE OIL FILTER (5D). Align oil level with upper

mark on ENGINE OIL DIPSTICK (5B). Use ENGINE OIL

DRAIN VALVE (3-1I, 3-2I) to drain engine oil:

• Remove DIAMOND BLADE (2E), and then lower saw

to a horizontal position.

• Raise and secure ENGINE HOOD (6E).

• Put a container, large enough to contain the engine

oil capacity, near the end of the oil drain hose. Open

ENGINE OIL DRAIN VALVE (3-1I, 3-2I) and allow

contents to drain into the container. Dispose of the used

engine oil in an environmentally safe manner. Securely

close ENGINE OIL DRAIN VALVE (3-1I, 3-2I). Fill with

recommended oil until oil level aligns with the upper

mark on ENGINE OIL DIPSTICK (5B).

LUBRICATE EVERY 100 HOURS:

• Front Axle Pivot Bearings (4C)

LUBRICATE EVERY 250 HOURS:

• Bladeshaft Seals and Bearings (4A) 2 Pumps only

HYDRAULIC SYSTEM:

Refer to Section 12 -“Hydraulic System”

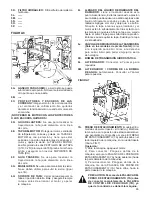

ENGINE GEARBOX (3-1A, 3-2A):

• Change oil after every 500 hours of operation. Use SAE

75W90 synthetic gear lubricant.

DO NOT OVERFILL! Fill only to “Check Port” or excess

will overflow.

Single Speed ENGINE GEARBOX (3-1A):

Oil Capacity

is 32 oz. (USA) (0.946 Liter)

Three Speed ENGINE GEARBOX (3-2A):

Oil Capacity

is 60 oz. (USA) (1.77 Liter)

• Drain cooling water from Water Drain Valve (3-1C, 3-2C)

to prevent rust and freeze damage (Every Day).

COOLING SYSTEM:

The engine cooling fluid is 50/50 anti freeze/water mixture.

See engine manual for recommendations.

• Clean the RADIATOR AIR FILTER ELEMENT (1DD)

every 50 hours or when required, replace if damaged.

Always keep RADIATOR AIR FILTER ELEMENT (1DD)

in place.

• Check hoses and hose clamps for damage and

looseness. Tighten or replace as required.

• Check Coolant Freeze Protection yearly.

• Flush and Clean radiator and cooling system every

500 hours.

• Maintain at least 1/4 full coolant level in RADIATOR

COOLANT OVERFLOW BOTTLE (1Y) when engine

is cool.

AIR FILTER:

• Clean the Air Filter Outer Element (5A) when the AIR

RESTRICTION INDICATOR (1N) Red Signal appears.

DO NOT clean the Inner Safety Element (5A)!

To change or clean the air filter element:

• Remove the Air Filter Housing (5A) by opening the

two (2) Air Filter Housing Clamps, and pulling the

housing off.

• Pull the Air Filter Outer Element out of the filter housing

and replace, or clean by using low pressure compressed

air [2.75 bars (40 psi) - MAXIMUM)] from the inside

out. DO NOT clean the filter element by tapping it

on the ground or other objects, this will damage the

filter element!

• Install the new or cleaned Air Filter Outer Element by

pushing it into the housing.

• Install the Air Filter Housing (5A) and close the two (2)

Air Filter Housing Clamps (5A).

The two (2) Air Filter Housing Clamps (5A)

can NOT be closed unless the Air Filter Outer

Element is properly installed.

Summary of Contents for FS 4800 D

Page 7: ... NOTES NOTAS REMARQUE ...

Page 31: ...31 NOTES NOTAS REMARQUE ...

Page 37: ...37 FS 4800 D DIESEL SPECIFICATIONS Standard CE Models ...

Page 39: ...39 ESPECIFICACIONES DE DIESEL FS 4800 D Modelos estándar y CE ...

Page 41: ...41 SPÉCIFICATIONS DU FS 4800 D DIESEL Modèles standards et CE ...

Page 112: ...542 20 10 97 2006 44 ...