ASSEMBLING AND ADJUSTMENTS

English

–

13

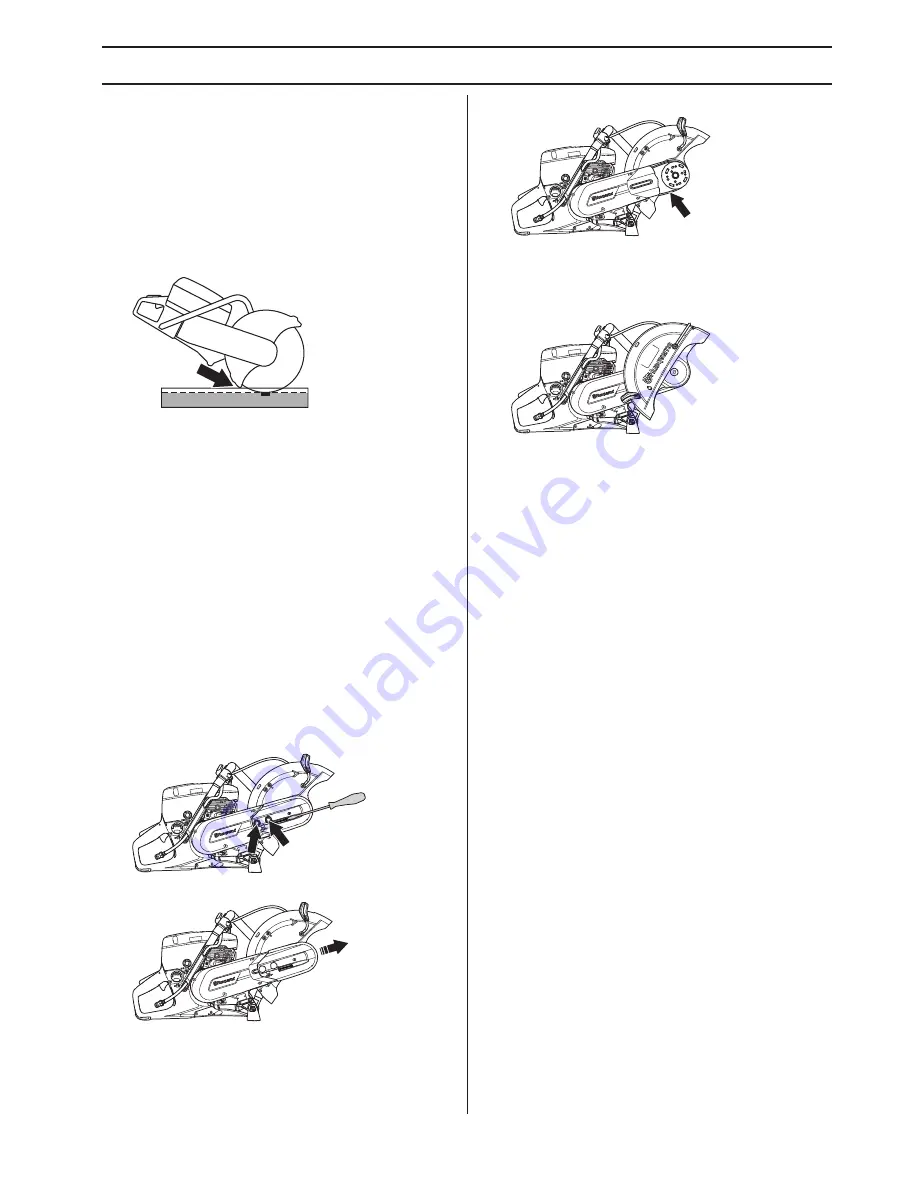

Blade guard

The guard for the cutting equipment should be adjusted

so that the rear section is flush with the work piece.

Spatter and sparks from the material being cut are then

collected up by the guard and led away from the user.

The blade guard is friction locked.

•

Press the ends of the guard against the work piece or

adjust the guard with the adjustment handle. The

guard must always be fitted on the machine.

Reversible cutting head (K 1270)

The machine is fitted with a reversible cutting head

allowing cutting close to a wall or at ground level,

restricted only by the thickness of the blade guard.

In the event of a kickback it is harder to control the

machine when cutting with the cutting head reversed. The

cutting blade is further away for the centre of the machine

which means the handle and the cutting blade are no

longer in alignment. It is more difficult to restrain the

machine if the blade gets jammed or stuck in its kickback

danger zone. See under the "Kickback" heading in the

"Operating" section for additional information.

Some of the machine’s good ergonomic features are

jeopardised such as balance. Cutting with the cutting

head reversed should only occur with cuts that are not

possible in a standard manner.

•

First release the two bolts and then the adjuster screw

to release the belt tension.

•

Now unscrew the bolts and dismantle the belt guard.

•

Remove the belt from the belt pulley.

•

The cutting head is now loose and can be removed

from the machine.

•

Remove the cutting head and attach it to the other

side of the cutting arm.

•

Fit the belt guard to the reversed cutting head.

•

Tighten the drive belt. See instructions in the section

"Maintenance".

•

Assemble the water hose nipple and the hose on the

opposite upper side of the blade guard.