opens. It also controls the quantity of fuel transmitted to

the fuel side of the measurement chamber.

2

1

2

6.6.15 To examine the fuel strainer

1. Examine the strainer with a magnifying glass.

2. Remove loose dirt particles from the seating of the

needle valve with air.

Replace the strainer if it is damaged. Remove with a

needle and install with a 7 mm pin punch.

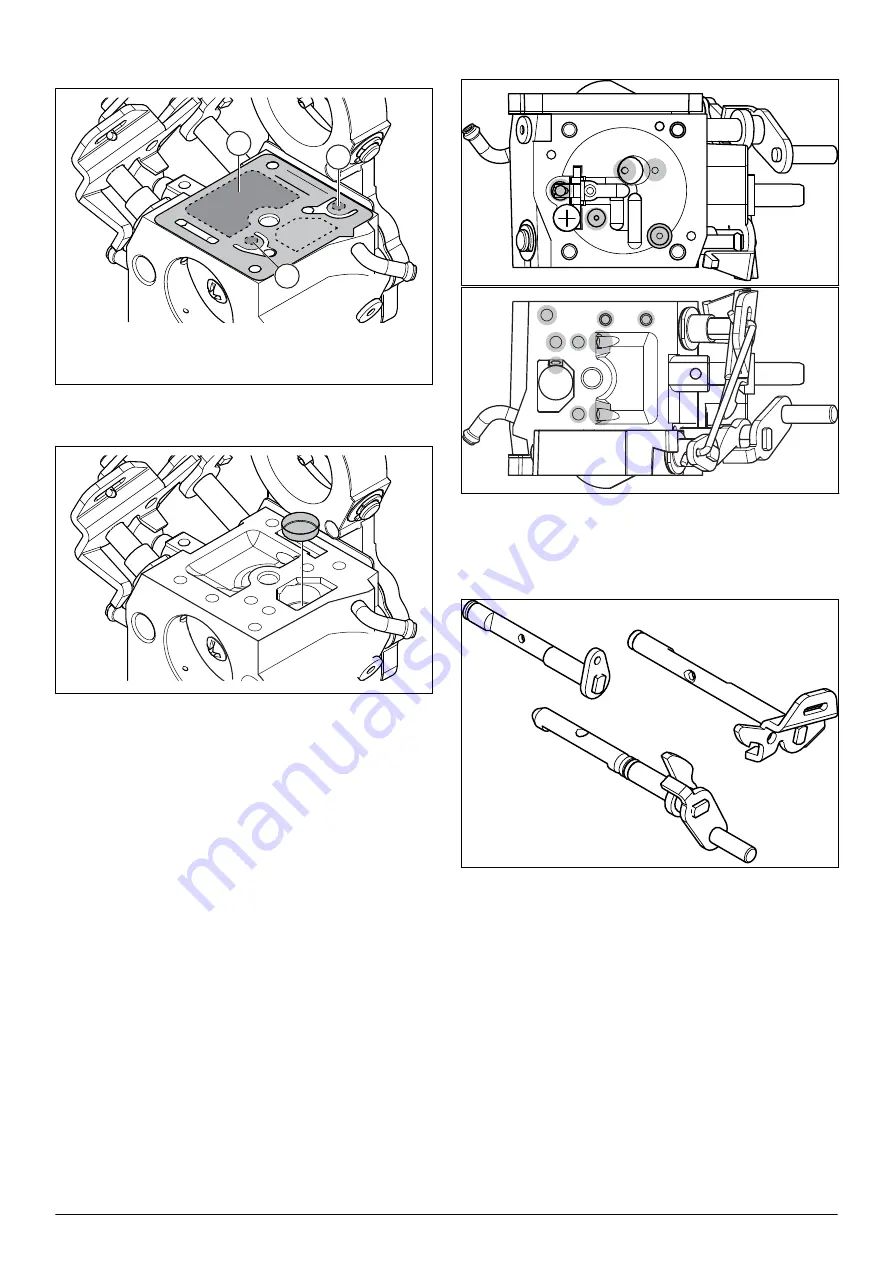

6.6.16 To clean the carburetor channels

When you do servicing on the carburetor, also blow out

particles from the channels with compressed air.

1. Disassemble the chamber diaphragm, the pump

diaphragm and the needle valve.

2. Open the choke valve to give free air flow through

the venturi.

3. Clean the channels with compressed air. The rings

show where to blow clean.

6.6.17 To examine the valve axles

Leakage from the valve axles results in incorrect fuel/air

mixture and dust in the engine.

1. Make sure there is no radial play on the valve axles.

2. Replace parts if necessary.

701 - 002 -

Repair and servicing - 43