MAINTENANCE

24 – English

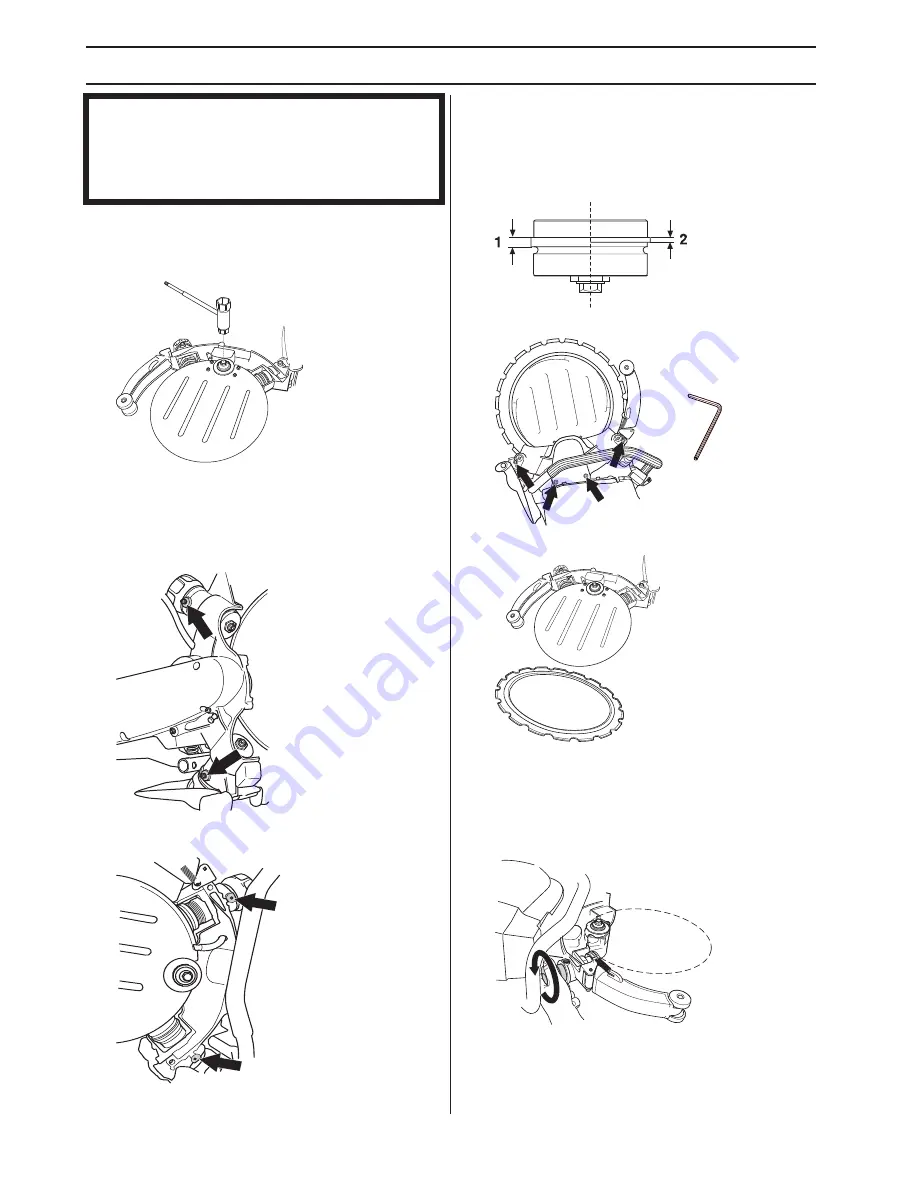

Replacing the drive wheel

•

Lock the axle using the locking button.

•

Loosen the centre screw and remove the washer.

•

You can now lift off the drive wheel.

Guide rollers

Lubricating the guide rollers

•

Connect the grease gun to the grease nipples.

•

Pump in grease until clean grease emerges from the

overflow hole.

Replacing the support guide rollers

•

Replace the guide rollers when half of the flange on

the rollers is worn.

1) New, 3 mm (0.12’’)

2) Worn,

≤

1,5 mm (0.06’’)

•

Remove the support roller cover.

•

Lift off the blade.

•

Unscrew the knob. First turn the knob a few turns until

you feel a resistance. The guide roller then follows the

knob out and stops when it feels a resistance.

The guide roller is pressed into the knob. In order to

loosen the guide roller, you need to continue turning

the knob until it loosens completely.

NOTICE! Replace the drive wheel when fitting a new

blade. A worn drive wheel can result in the blade

slipping and becoming damaged.

Inadequate water flow drastically shortens the life of the

drive wheel.