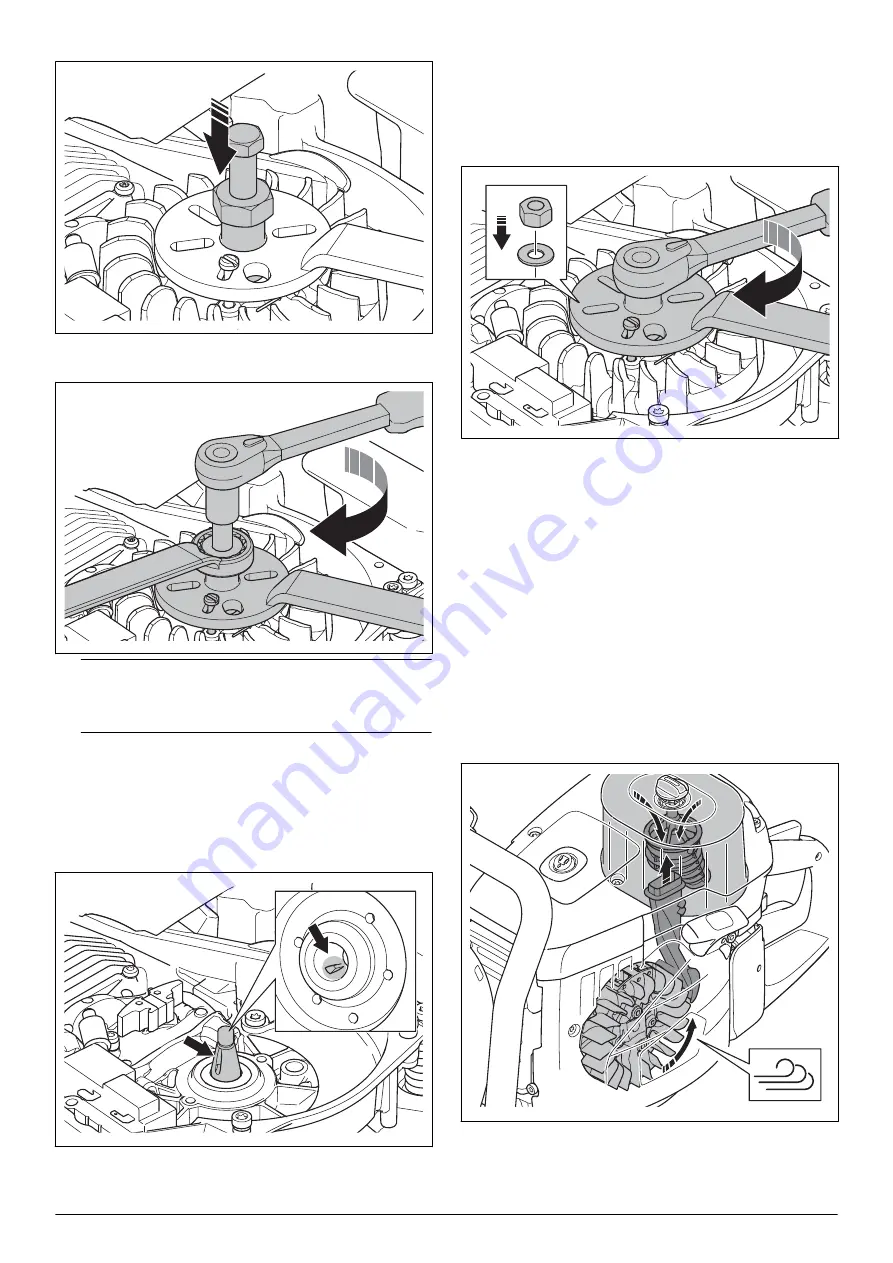

7. Attach the screw press in the center.

8. Lock the outer socket with a wrench and tighten the

center screw until the flywheel releases.

Note: If the flywheel is not easy to remove, hit the

center screw with a hammer. At the same time, lift

the product with the handle of the flywheel puller.

6.3.2 To examine the seat and key

The key in the flywheel can not be replaced. If the key is

damaged, the flywheel must be replaced. For a correct

ignition point, the position of the flywheel must align with

the position of the crankshaft. The force of the center nut

is not sufficient to hold the flywheel in the right position.

6.3.3 To install the flywheel

The crankshaft and the center of the flywheel must be

free from grease. Tightening torque 18 – 22 lbf·ft / 25 –

30 Nm. Use a torque wrench to tighten the nut.

1. Align the key in the flywheel with the keyway on the

crankshaft. Install the washer and nut.

2. Remove the tool and put the springs on the starter

pawls.

6.4 Air filter

6.4.1 Function of the air filter

The centrifugal cleaning is the first step in the process to

clean the inlet air. The blades on the flywheel supply the

cylinder with cool air. This is shown in the illustration.

The blades are also the part in operation on the

centrifugal cleaning of the inlet air of the engine. An inlet

tube is installed near the blades on the flywheel. The

centrifugal force prevents large particles in the inlet tube.

The centrifugal force pushes the large particles out

before they can go into the tube. Only small dust

particles go with the air to the inlet.

1451 - 001 - 02.04.2020

Repair and servicing - 31