6.6.4 Pump unit function

The pump diaphragm (A) receives power by changes of

pressure in the crankcase. The pressure changes are

caused by the piston movement and transmitted to the

top of the pump diaphragm. The fuel below the

diaphragm is pushed to the valves (B). Pressure from

the measurement chamber diaphragm to the needle

valve in the measurement chamber controls how much

the valve opens. It also controls the quantity of fuel

transmitted to the fuel side of the measurement

chamber.

B

A

B

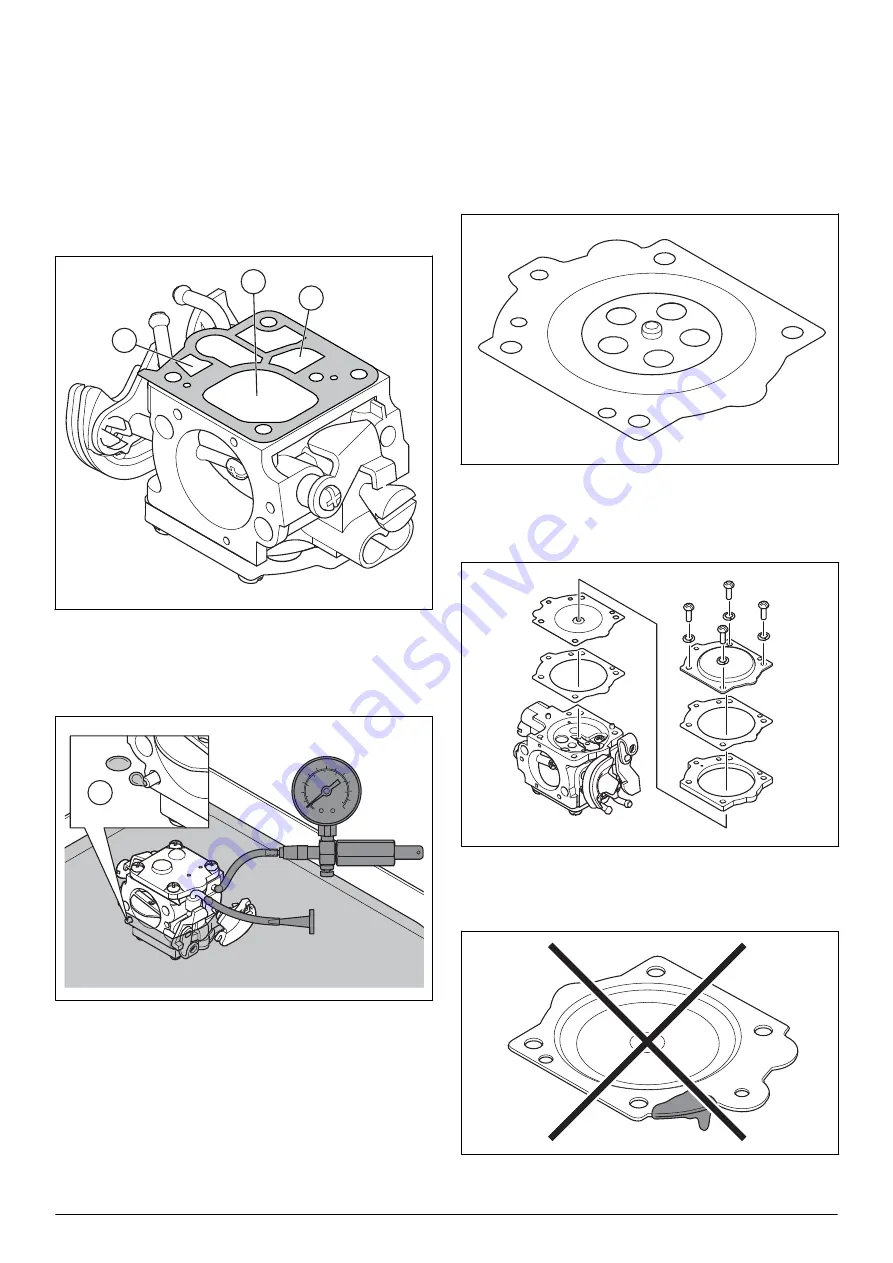

6.6.5 To examine the fuel pump diaphragm

1. Connect the pressure tester to the fuel line.

2. Increase the pressure to to a maximum of 36 psi/ 2.5

bar.

A

If air comes out of the impulse channel (A), the pump

diaphragm is broken.

6.6.6 Function of the measurement chamber

The product has SmartCarb

™

filter compensation. The

measurement chamber has an air chamber to the cover

and a fuel chamber to the carburetor body. The air

chamber and the fuel chamber are divided by the

measurement chamber diaphragm. The diaphragm

controls and keeps a constant level of fuel in the fuel

chamber through the mechanically connected needle

valve. The air chamber is near the inlet, after the air

filters, and gives the air chamber the same pressure.

You cannot examine the chamber diaphragm with a

pressure check. To examine the diaphragm, refer to

examine the measurement chamber diaphragm on page

39. A hole in the diaphragm stops the fuel supply.

6.6.7 To examine the measurement chamber

diaphragm

1. Remove the 4 screws and disassemble the

measurement chamber.

2. Examine the chamber diaphragm visually. Fuel on

the top side, against the cover, is a sign of leaks. If

there is fuel on the top side, replace the chamber

diaphragm.

1451 - 001 - 02.04.2020

Repair and servicing - 39