4.2

Section 4

Air Cleaner and Air Intake System

3. Wash the precleaner in warm water with

detergent. Rinse the precleaner thoroughly until

all traces of detergent are eliminated. Squeeze

out excess water (do not wring). Allow the

precleaner to air dry.

4. Saturate the precleaner with new engine oil.

Squeeze out all excess oil.

5. Reinstall the precleaner into the outer cover.

6. Install the air cleaner cover and secure with the

two knobs.

7. When precleaner replacement is necessary, order

Kohler Part No.

20 083 01-S

.

Paper Element Service

Check the paper element

every two months

or

every

25 hours

of operation (more often under extremely

dusty or dirty conditions). Clean or replace the element

as necessary. Replace the air cleaner element

annually

or

every 100 hours

.

1. Remove the air cleaner cover and the precleaner

(if so equipped), service as required.

2. Remove the air cleaner element with the integral

rubber seal.

3. Gently tap the pleated side of the paper element

to dislodge dirt.

Do not

wash the paper element

or use pressurized air, as this will damage the

element. Replace a dirty, bent, or damaged

element with a genuine Kohler element. Handle

new elements carefully; do not use if the rubber

seal is damaged.

4. Clean all air cleaner components of any

accumulated dirt or foreign material. Prevent any

dirt from entering the throat of the carburetor.

5. Install the air cleaner element with the pleated

side out and seat the rubber seal onto the edges

of the air cleaner base.

6. Reinstall the precleaner (if so equipped), into the

upper section of the air cleaner cover. Make sure

the hole in the precleaner is aligned with the

upper mounting knob. See Figure 9.

7. Reinstall the air cleaner cover and secure with the

two knobs.

8. When element replacement is necessary, order

Kohler Part No.

20 083 02-S

.

Inspect Air Cleaner Components

Whenever the air cleaner cover is removed, or the

paper element or precleaner is serviced, check the

following areas/components:

Outer Air Cleaner Cover

- Make sure the air cleaner

cover is in good condition, not cracked, damaged, or

missing a retaining knob, which can affect the sealing

ability of the air cleaner element.

Air Cleaner Base

- Make sure the base is properly

secured and not cracked or damaged. Since the air

cleaner base and carburetor are secured to the intake

port with common hardware, it is extremely important

that the fasteners securing these components are tight

at all times. The air cleaner base also provides the

mounting points for the air cleaner cover retaining

studs. Make sure the bosses are not cracked, broken

or damaged, and the studs are properly secured.

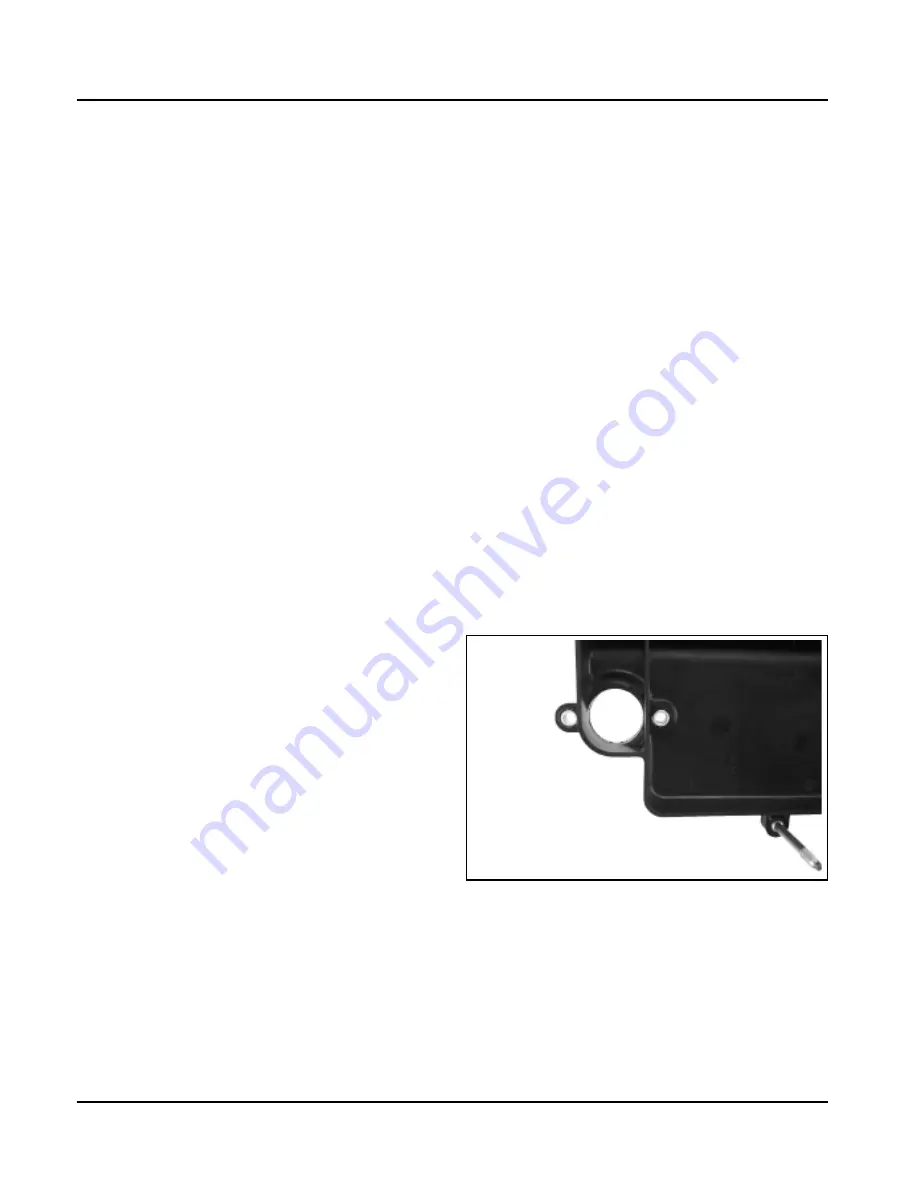

Before reinstalling an air cleaner base that has been

removed, make sure the metal bushings in the base

mounting holes are present. See Figure 4-2. The

bushings prevent damage to the base and maintain

the proper mounting torque.

Figure 4-2. Bushings in Air Cleaner Base.

Breather Hose

- Make sure the hose is not cracked or

damaged, and attached to both the air cleaner base

and valve cover.

NOTE: Damaged, worn, or loose air cleaner

components can allow unfiltered air into the

engine causing premature wear and failure.

Tighten or replace all loose or damaged

components.

Summary of Contents for Kohler SV470

Page 1: ...Workshop manual Kohler Courage Tractor Engines English ...

Page 3: ......

Page 17: ...1 14 Section 1 Safety and General Information ...

Page 43: ...5 16 Section 5 Fuel System and Governor ...

Page 93: ...9 14 Section 9 Inspection and Reconditioning ...

Page 116: ...2004W27 114 03 04 26 ...