23

SERVICE AND ADJUSTMENTS

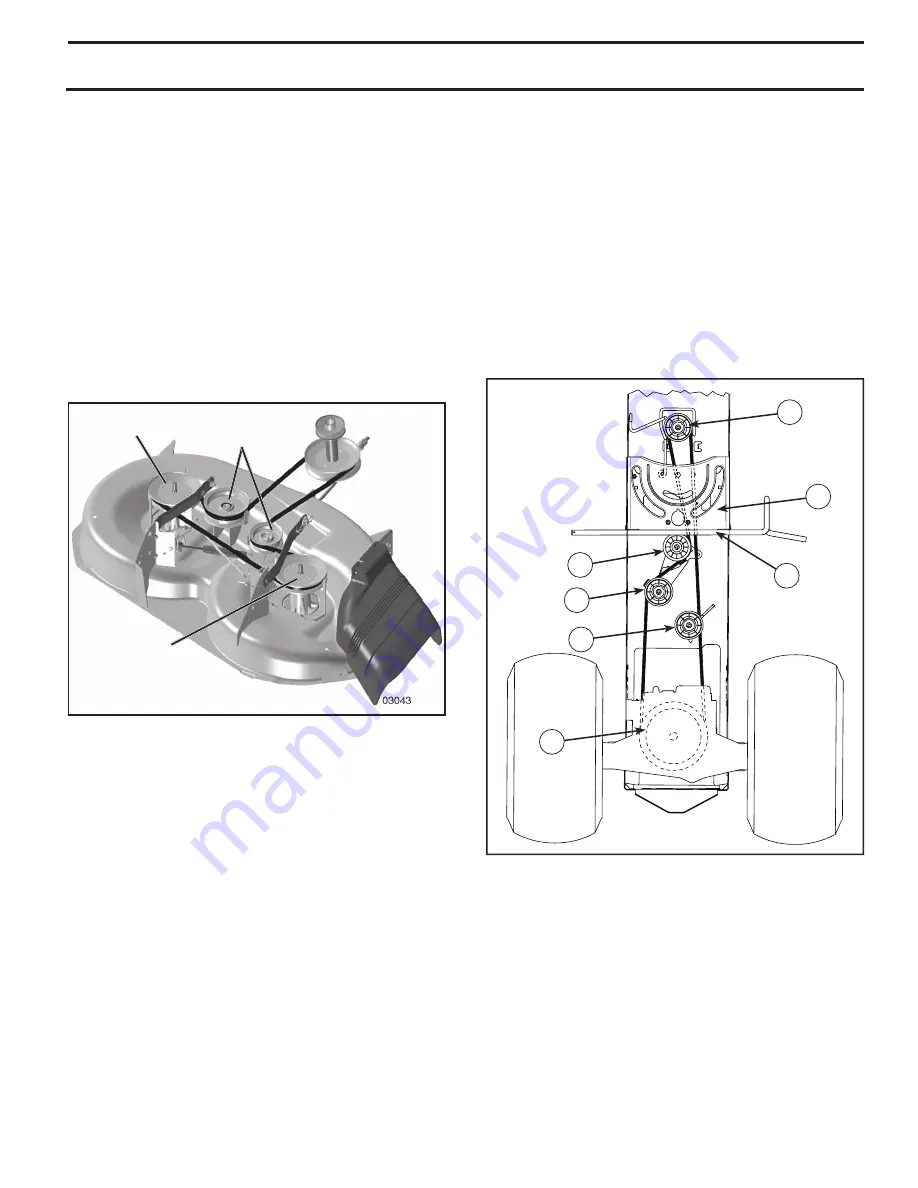

FIG. 32

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 31)

The mower blade drive belt may be replaced without tools.

Park the tractor on level surface. Engage parking brake.

BELT REMOVAL -

• Remove mower from tractor (See “TO REMOVE

MOW ER” in this section of manual).

• Work belt off both mandrel pulleys and idler pulleys.

• Pull belt away from mower.

BELT INSTALLATION -

•

Work belt around both mandrel pulleys and idler pulleys.

• Make sure belt is in all pulley grooves and in side all

belt guides.

•

Install mower (See "To Install Mower" in this section of

manual).

FIG. 31

MANDREL

PULLEY

IDLER

PUL LEYS

MANDREL

PULLEY

TO REPLACE MOTION DRIVE BELT

(See Fig. 32)

Park the tractor on level surface. En gage parking brake.

For as sis tance, there is a belt installation guide decal on

bottom side of left footrest.

BELT REMOVAL -

•

Remove mower (See “TO REMOVE MOWER” section

in this manual).

NOTE:

Observe entire motion drive belt and position of all

belt guides and keepers.

• Remove belt from stationary idler (A) and clutching

idler (B).

• Remove belt from centerspan idler (C).

•

Pull belt slack toward rear of trac tor. Carefully remove

belt up wards from trans mis sion input pulley and over

cooling fan blades (D).

• Remove belt downward from engine pulley (E).

• Slide belt toward rear of tractor, off the steering plate

(F) and remove from tractor.

02952

A

B

C

D

E

F

G

BELT INSTALLATION -

•

Install new belt from tractor rear to front, over the steer-

ing plate (F) and above clutch brake pedal shaft (G).

•

Pull belt toward front of tractor and roll belt onto engine

pulley (E).

•

Pull belt toward rear of tractor. Carefully work belt down

around transmission cooling fan and onto the input

pulley (D). Be sure belt is inside the belt keeper.

• Install belt on centerspan idler (C).

• Install belt through stationary idler (A) and clutch ing

idler (B).

• Make sure belt is in all pulley grooves and in side all

belt guides and keep ers.

• Install mower (See “TO INSTALL MOWER” section in

this manual).