14

15

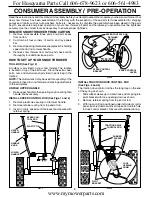

DRIVE SPEED

CONTROL LEVER

TRACTION DRIVE

CONTROL LEVER

FIG. 18

CONSUMER

OPERATION

snow.

TO MOVE FORWARD AND BACKWARD (See Fig. 18)

SELF-PROPELLING, forward and reverse movement of

the snow thrower, is controlled by the traction drive control

lever located on the left side handle.

• Squeeze traction drive control lever to handle to engage

the drive system.

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

SPEED and DIRECTION are controlled by the drive speed

control lever.

• Press downward on the speed control lever and move

lever to desired position BEFORE engaging the trac-

tion drive control lever. Be sure lever springs back and

locks into desired position.

CAUTION: Do not move speed control lever

when traction drive control lever is engaged.

Damage to the snow thrower can result.

• Slower speeds are for heavier snow and faster speeds

are for light snow and transporting the snow thrower. It

is recommended that you use a slower speed until you

are familiar with the operation of the snow thrower.

NOTE:

When both traction drive and auger control levers

are engaged, the traction drive control lever will lock the

auger control lever in the engaged position. This will allow

you to release your right hand from the handle and adjust

the discharge chute direction without interrupting the snow

throwing process.

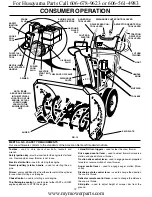

POWER STEERING OPERATION (See Fig. 19)

Steering triggers are used to assist in steering your snow

thrower. The triggers are located on the underside of each

handle. When a trigger is squeezed, it disengages the drive

wheel on that side of snow thrower and allows it to turn in

that direction.

• To turn left – squeeze left side trigger.

• To turn right – squeeze right side trigger.

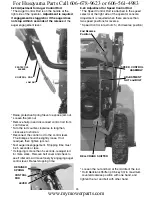

TO ADJUST SKID PLATES (See Fig. 20)

NOTE:

The wrench provided in your parts bag may be used

to adjust the skid plates.

Skid plates are located on each side of the auger housing

and adjust the clearance between the scraper bar and the

ground surface. Adjust skid plates evenly to proper height

for current surface conditions. For removal of snow in

normal conditions, such as a paved driveway or sidewalk,

place skid plates in the highest position (lowest scraper

clearance) to give a 1/8" clearance between the scraper

bar and the ground. Use a middle position if the surface

to be cleared is uneven.

NOTE:

It is not recommended to operate the snow thrower

over gravel or rocky surfaces. Objects such as gravel, rocks

or other debris, can easily be picked up and thrown by the

impeller, which can cause serious personal injury, property

damage or damage to the snow thrower.

• If snow thrower must be operated over gravel surface,

use extra caution and be sure skid plates are adjusted

to lowest (highest scraper clearance) position.

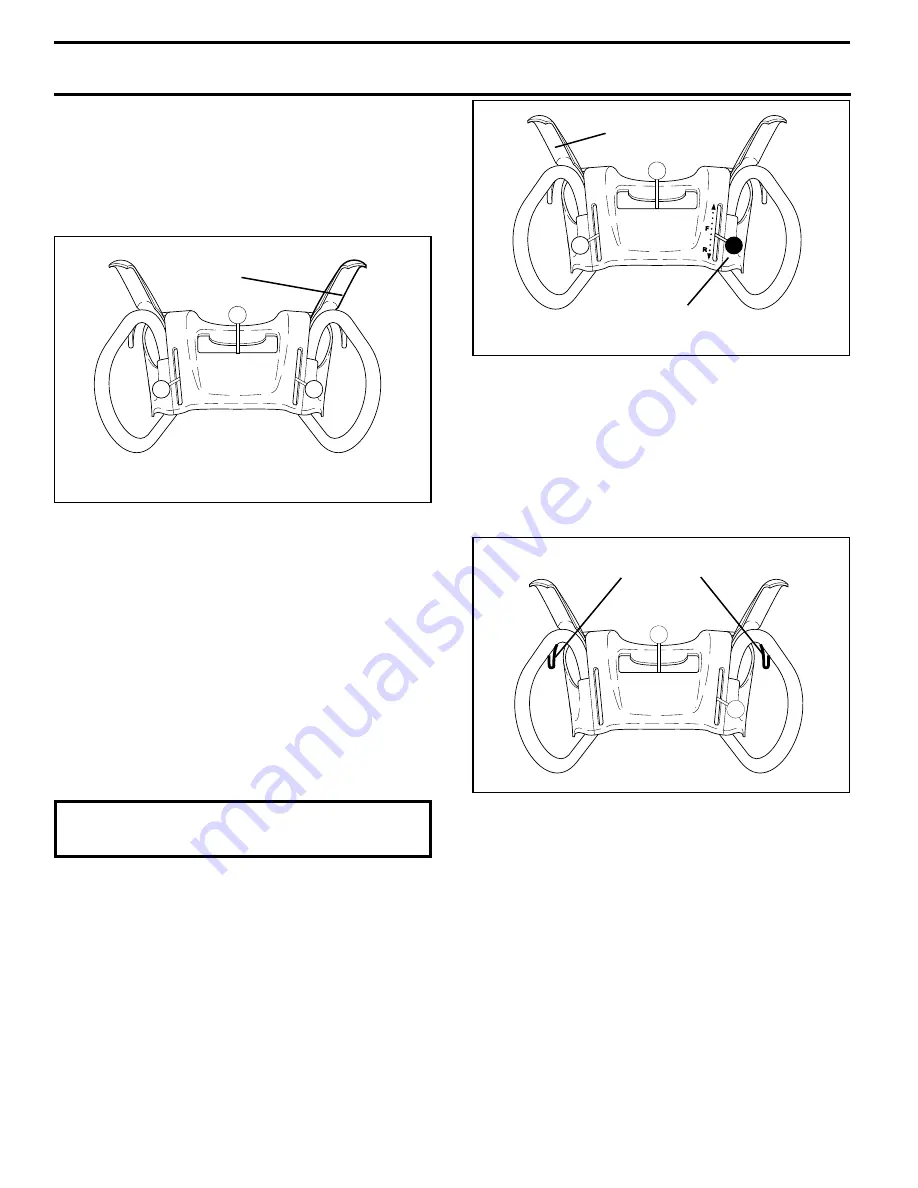

TO THROW SNOW (See Fig. 17)

The auger rotation is controlled by the auger control lever

located on the right side handle.

• Squeeze auger control lever to handle to engage the

auger and throw snow.

• Release the auger control lever to stop throwing

LH TURN TRIGGER RH TURN TRIGGER

FIG. 19

AUGER CONTROL

LEVER

FIG. 17

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com