10

SERVICING THE BATTERY

Use the following procedure when removing, installing and

attaching the battery cables.

The battery is located in the support foot of the power pack.

To access the battery you will need another person helping

you.

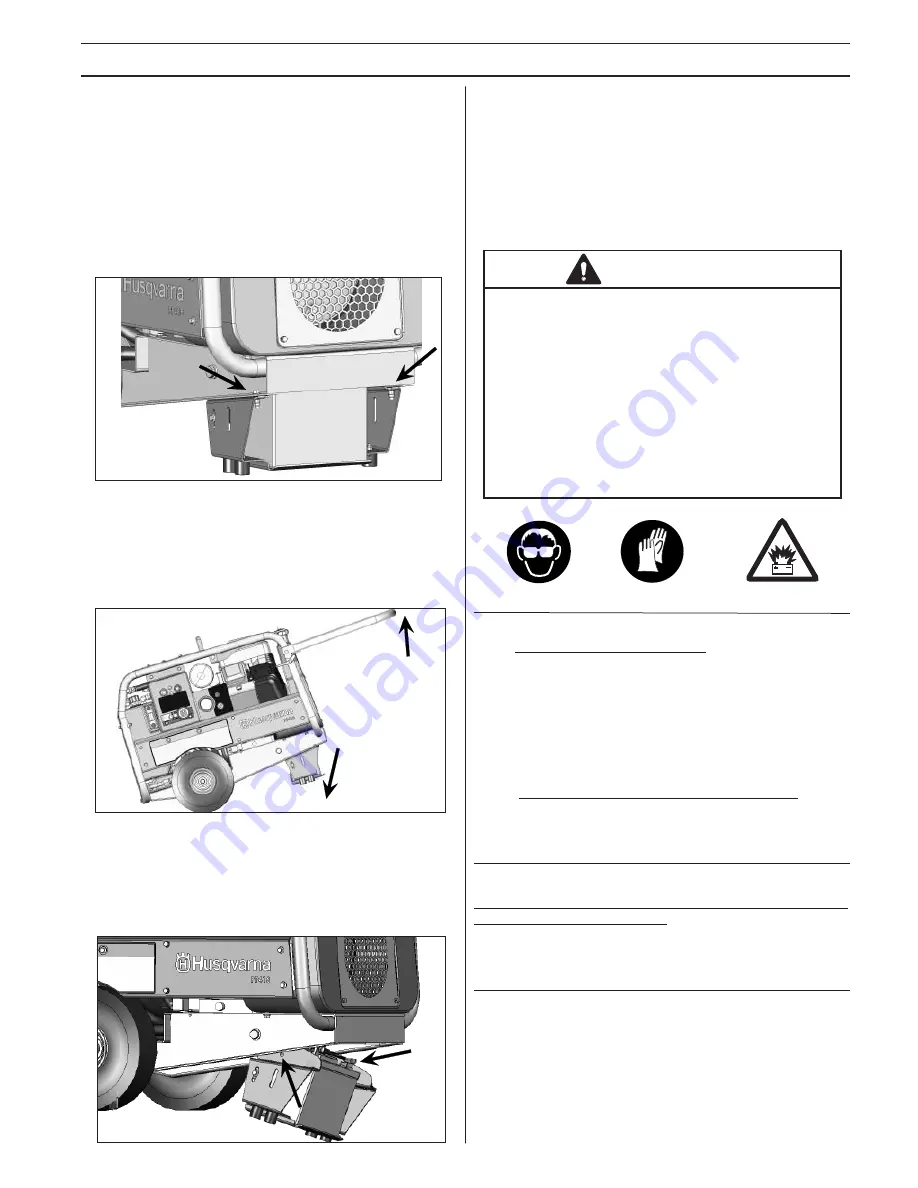

Step 1

Remove the two M8 bolts using a 10 mm wrench. Keep the

two bolts nearby for Step 3

WARNING

- Connecting and disconnecting a battery can cause

sparks and short circuits. Do not short battery ter-

minals by allowing a wrench or any other object to

contact both terminals at the same time.

- A spark or fl ame can cause a lead acid battery to

explode.

- Before connecting a battery, remove metal

bracelets, wristwatch bands, rings, etc. Use gloves

and protective glasses or face shield when working

with a battery.

- Install and remove the battery cables ONLY in the

sequence described in this section.

Step 2

Have one person lift the power pack with the handle. With the

“battery box” no longer supporting the power pack it can be

pivoted downward. This will give you full access to the battery

and cables.

Step 3

Secure the battery box in the “open” position by inserting the

two M8 screws removed in Step 1 into the exposed holes in

the battery box (see illustration). Use one bolt on each side.

The battery supplied as original equipment is maintenance

free. Do not attempt to open or remove caps or covers.

Adding or checking the electrolyte level is not necessary.

Replace only with an equivalent maintenance free battery with

the following specifi cations;

Case size:

U1

Min. CCA:

230

CONNECTING A BATTERY

First

- always install the RED (+) cable to the positive (+)

terminal on the battery. Secure the cable to the terminal with

the 5/16” screw and nut. (13 mm or 1/2” wrench).

Second

- install the BLACK (-) ground cable to the negative (-)

terminal on the battery. Secure the cable to the terminal with

the 5/16” screw and nut.

DISCONNECTING A BATTERY

First

- always disconnect the BLACK (-) ground cable from

the battery. (13 mm or 1/2” wrench).

Second

- disconnect the RED (+) cable.

CHARGING A BATTERY

The only safe way to charge a battery is to completely remove

the battery from the power pack. A standard battery charger

can be used with a charging power of 12 volt and 2 to 10 amp.

Follow all instructions for your battery charger before hooking it

up to the battery.

JUMPER CABLES

DO NOT

use jumper cables between the power pack and a

secondary battery source such as a car.

If the battery is weak and can not start the engine either

remove and recharge or replace the battery. Do not attempt

to use jumper cables. There is no safe way to attach jumper

cables.

Lift and support the

power pack by pulling

up on the handle.

Eye Protection

Explosion Danger

Protective Gloves

The battery box

can be pivoted

downward.

Summary of Contents for PP 418

Page 19: ...19 ...