9

ASSEMBLY

NOTICE

The PP 418 power pack must be serviced before use.

In some markets the power pack will be delivered

fi lled with both engine oil and hydraulic oil.

Remove the power pack from its shipping material and place it

on a level surface.

Step 1

Check the engine oil level. If no oil is present on the dipstick

add oil in accordance to the recommendations on page 8 or

consult the BRIGGS & STRATTON Operator’s Manual.

CAUTION

Only use the lifting eyelet when lifting the power pack.

Dipstick

Oil

Fill

Full

SAE 30

Step 2

Fill the hydraulic oil tank.

Use only a high quality hydraulic oil – ISO 46. See page 8

for other alternatives. The total fi rst time oil amount needed is

10 liters (2.6 gal) to fi ll the tank. The oil should be fi lled to the

middle of the sight glass.

The oil level must be rechecked and refi lled after the initial test

running has been done - see page 12.

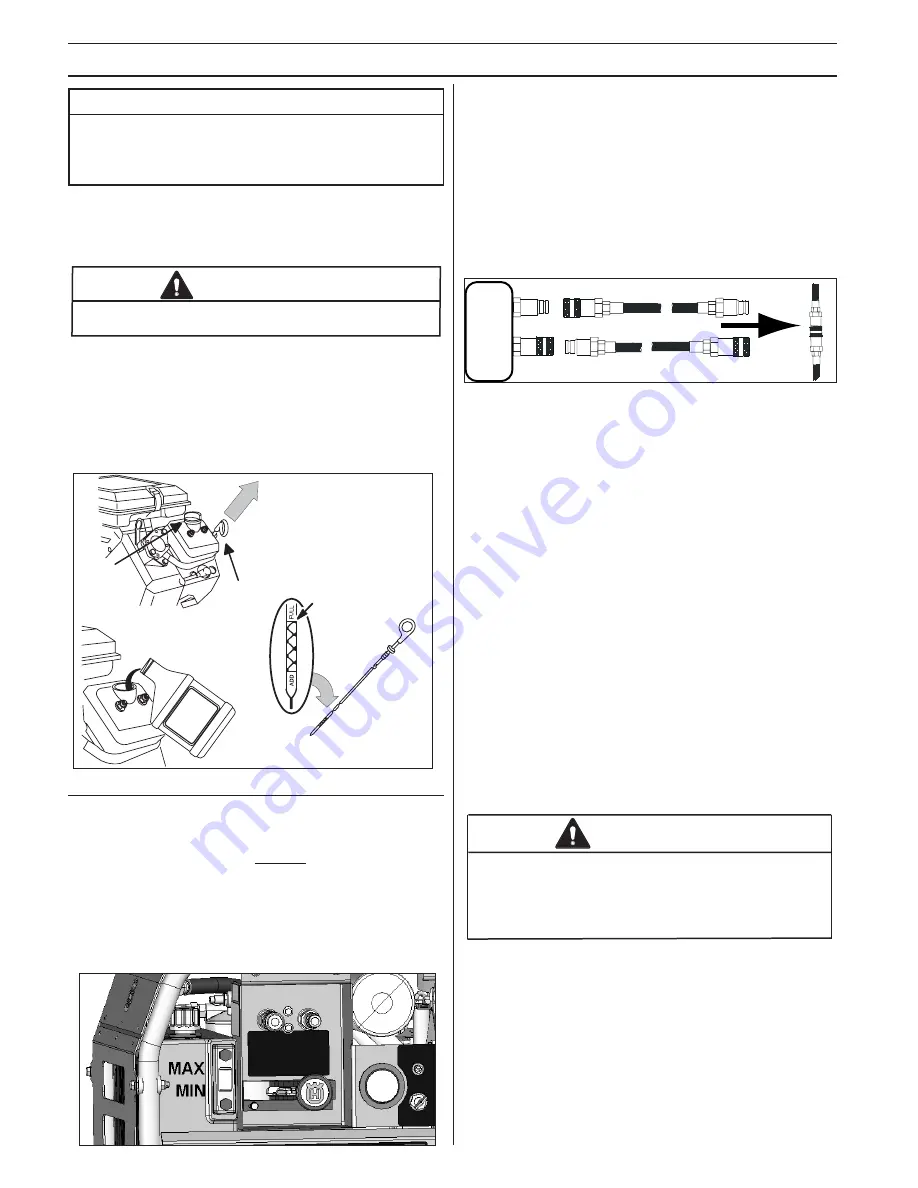

Step 3

Hook up the hydraulic hoses to the power pack. Connect the

two couplers in the free end of the hose. The hoses are now

ready to be charged with oil from the oil tank.

NOTE:

The hoses can be installed with either end to the power pack.

Any set of hoses assembled with the couplers as in this

illustration will always have full compatibility between power

pack, hoses and tool.

P

O

W

E

R

P

A

C

K

M

A

N

I

F

O

L

D

Female

Male

Male

Female

Step 5

The power pack is delivered without the battery cables

installed to the battery. Please read;

SERVICING THE BATTERY on page 10.

The original equipment battery is maintenance free. Do not

attempt to open or remove caps or covers. Adding or checking

the level of electrolyte is not necessary.

WARNING

Lead-acid batteries generate explosive gases.

Keep sparks, fl ame and smoking materials away from

batteries. Always wear eye protection when around

batteries.

Step 4

Check the tire pressure. The wheels are tubeless. If the tire

pressure becomes too low the wheel will defl ate completely.

Infl ate to 2 bar (30 psi)

If the hydraulic hoses (7.5 m/25 ft) are empty they will require

approximately 1.8 liters (2 quarts) of additional oil to be added

to the oil tank after running the power pack for the fi rst time.

If an additional 30 m (100 ft) of 5/8” hose set is used they will

require approximately 12 liters (3.2 gal) to be added. The oil

level in the oil tank must be rechecked several times when

fi lling a new hose set.

Step 6

Fill the fuel tank with fresh clean gasoline. See warnings and

recommendations on page 8. Add only fuel in a quantity that

will be used within 30 days to assure fuel freshness. If the

power pack is stored with fuel in the tank for longer periods we

recommend to use a commercially available “Fuel Stabilizer”.

Summary of Contents for PP 418

Page 19: ...19 ...