English-

9

SPECIAL TOOLS

Special Tools

The machine is designed so that the number of special tools is kept to a minimum.

The following special tools are used when working on the rider.

Special tools for the engine and transmission are specified in resp. Workshop Manuals.

1 set of torque wrenches 4-100 Nm.

1 torque wrench 200 Nm.

Open ring spanners for tightening hydraulic connections.

17, 19, 22, 27, 32 mm.

Torx screwdriver T-25.

Cross tip screwdriver set Phillips (marking P).

Cross tip screwdriver set Pozidrive (markingPZ).

Metric threads are used on the machine.

Exception, the following components have imperial threads:

•

Hydraulic components from:

Sauer-Danfoss.

•

Brake.

Special tools

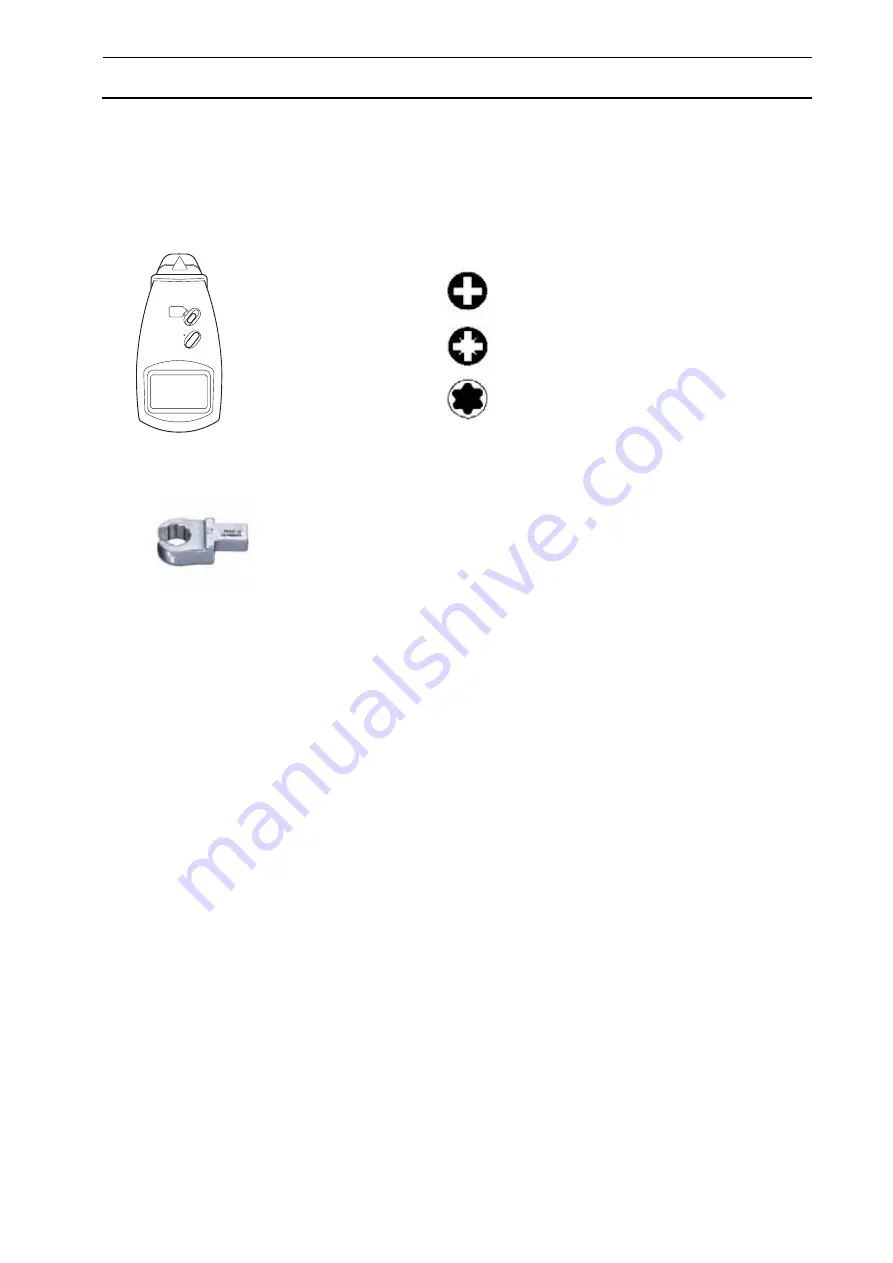

RPM

TOT

MEM

DIGITAL TACHOMETER

8009-853

Laser tachometer

8043-159

Screw types

Phillips

Pozidrive

Torx

8043-161

Open ring spanner adapter for

torque wrench (Bacho)

Summary of Contents for PT 26D

Page 1: ...Workshop manual PT26D English ...

Page 13: ...English 12 SPECIAL TOOLS ...

Page 94: ...English 93 REPAIR INSTRUCTIONS 8043 197 Cutting unit Combi 155 ...

Page 107: ...English 106 REPAIR INSTRUCTIONS ...

Page 123: ...English 122 REPAIR INSTRUCTIONS ...

Page 145: ......

Page 146: ...English 145 APPENDIXES Circuit diagram Circuit diagram 1 ...

Page 147: ...English 146 APPENDIXES Circuit diagram 2 ...

Page 148: ...English 147 APPENDIXES Circuit diagram 3 ...

Page 149: ...English 148 APPENDIXES Circuit diagram 4 ...

Page 150: ...English 149 APPENDIXES Circuit diagram 5 ...

Page 151: ...English 150 APPENDIXES Circuit diagram 6 ...

Page 152: ...English 151 APPENDIXES Circuit diagram 7 ...

Page 153: ...English 152 APPENDIXES Circuit diagram 8 ...

Page 154: ...English 153 APPENDIXES Circuit diagram 9 ...

Page 155: ...English 154 APPENDIXES Circuit diagram 10 ...

Page 156: ...English 155 APPENDIXES Circuit diagram 11 ...

Page 157: ...English 156 APPENDIXES ...

Page 161: ...English 160 APPENDIXES 8043 160 Circuit board placement ...

Page 162: ...English 161 APPENDIXES Hydraulic diagram 8043 247 Hydraulic diagram ...

Page 163: ...English 162 APPENDIXES ...

Page 167: ...2009W18 115 08 30 26 ...