English-

123

TROUBLE SHOOTING

Trouble shooting

General

The main rule for all trouble shooting is to work methodically. Note what you do and any observations from

the beginning of the work.

This is something that is often neglected. The notes are valuable, partly if you want to check what you have

done – not done, partly when you need to motivate the working hours for trouble shooting.

Also note down how electrical wires are connected before you disconnect them. It can happen that some-

one has made an incorrect connection before and this can cause a malfunction.

Use the wiring diagram and hydraulic diagram to assist you in your work. Look to see whether there are

components in circuits, that do not withstand the load of a short circuit test, perhaps not even the load from

a common test lamp.

When you have found a fault, as a rule, you need to consider: Is this the original fault or has it been caused

by another fault?

Remember that virtually all trouble shooting is an investigation, so be careful not to destroy and “evidence”.

Engine with accessories

See Perkins Manual tab SOTA (System Operation Test and Adjust).

Compression test

See Perkins Manual \ SOTA \ Air inlet and Exhaust System \ Compression – Test.

Cooling system

See Perkins Manual \ SOTA \ Cooling System \ Check, Inspect and Test.

Coolant pump

See Perkins Manual \ SOTA \ Cooling System \ Water Pump – Inspect.

Inspection of the fuel system

See Perkins Manual \ SOTA \ Fuel system Inspect and Air in Fuel – Test.

Inspection of the injector

See Perkins Manual \ SOTA \ Fuel system \ Fuel Injector – Test.

Inspection of the alternator with regulator

See Perkins Manual \ SOTA \ Electrical System \ Alternator – Test and Charging System – Test.

Inspection of the starter motor

See Perkins Manual \ SOTA \ Electrical System \ Electric Starting System – Test.

Inspection of the sensors and switches

See Perkins Manual \ SOTA \ Electrical System \ Coolant Temperature Switch – Test and Oil Pressure

Switch – Test.

Inspection of the glow plug

See Perkins Manual \ SOTA \ Electrical System \ Glow Plugs – Test and Glow Plug Circuit – Test.

Summary of Contents for PT 26D

Page 1: ...Workshop manual PT26D English ...

Page 13: ...English 12 SPECIAL TOOLS ...

Page 94: ...English 93 REPAIR INSTRUCTIONS 8043 197 Cutting unit Combi 155 ...

Page 107: ...English 106 REPAIR INSTRUCTIONS ...

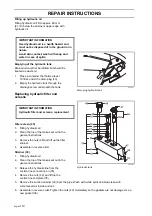

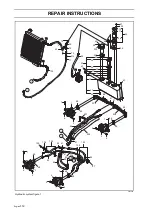

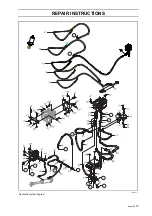

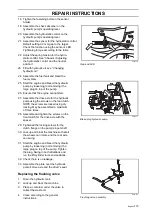

Page 123: ...English 122 REPAIR INSTRUCTIONS ...

Page 145: ......

Page 146: ...English 145 APPENDIXES Circuit diagram Circuit diagram 1 ...

Page 147: ...English 146 APPENDIXES Circuit diagram 2 ...

Page 148: ...English 147 APPENDIXES Circuit diagram 3 ...

Page 149: ...English 148 APPENDIXES Circuit diagram 4 ...

Page 150: ...English 149 APPENDIXES Circuit diagram 5 ...

Page 151: ...English 150 APPENDIXES Circuit diagram 6 ...

Page 152: ...English 151 APPENDIXES Circuit diagram 7 ...

Page 153: ...English 152 APPENDIXES Circuit diagram 8 ...

Page 154: ...English 153 APPENDIXES Circuit diagram 9 ...

Page 155: ...English 154 APPENDIXES Circuit diagram 10 ...

Page 156: ...English 155 APPENDIXES Circuit diagram 11 ...

Page 157: ...English 156 APPENDIXES ...

Page 161: ...English 160 APPENDIXES 8043 160 Circuit board placement ...

Page 162: ...English 161 APPENDIXES Hydraulic diagram 8043 247 Hydraulic diagram ...

Page 163: ...English 162 APPENDIXES ...

Page 167: ...2009W18 115 08 30 26 ...