English-

115

REPAIR INSTRUCTIONS

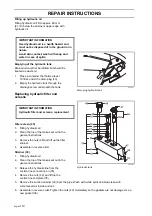

18. Tighten the fastening bolts on the sensor

holder.

19. Assemble the shock absorber on the

hydraulic pump's operating lever.

20. Assemble the hydrostatic control on the

hydraulic pump's operating lever.

21. Assemble the sensor for the hydrostatic control.

Default setting 2-3 mm gap to the target.

Check the function using the sensor’s LED.

Tightening torque according to the table.

22. Adjust the spring tension for the hydro-

static control. See “Chassis \ Adjusting

the hydrostatic control and the neutral

position”.

23. Fill with hydraulic oil, see “Changing

hydraulic oil”.

24. Assemble the fuel tank and bleed the

fuel system.

25. Start the engine and bleed the hydraulic

pump by loosening (not removing) the

large plug on top of the pump.

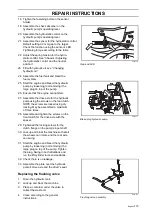

26. Ensure that the engine cannot start.

27. Assemble the drive axle for the hydraulic

pump using the screws on the rear clutch.

NOTE the screws are locked using dry

locking. May be assembled a maximum

of three times.

28. Assemble and tighten the screws on the

front clutch for the drive axle with the

spacer.

29. Tightened the locking screws for the

clutch flange on the pump’s input shaft.

30. Jack up and block the machine so that all

the wheels can rotate and the rear axle

can swing.

31. Start the engine and bleed the hydraulic

pump by loosening (not removing) the

large plug on top of the pump. Tighten

the plug. Swing in both directions and

run the lift cylinder to its end positions.

32. Check there is no leakage.

33. Assemble the plate over the hydraulic

pump's drive axle and the driver’s seat.

Replacing the flushing valve

1.

Drain the hydraulic tank.

2.

Jack up and block the machine

3.

Place a container under the valve to

collect the waste oil.

4.

Clean according to the general

instructions.

8043-120

Gap and LED

S

Model-No./Ident-No

.

Model Code

MPVO25CB

AYRA

CNNAAB

DDDRAFFANNN

***

DA

M25-2136

K-06-10-06573

Made in USA

Serial-N0.

NFO

SS

A UE

R

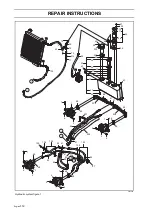

8043-121

Bleed plug hydraulic pump

8043-124

Flushing valve, assembly

Summary of Contents for PT 26D

Page 1: ...Workshop manual PT26D English ...

Page 13: ...English 12 SPECIAL TOOLS ...

Page 94: ...English 93 REPAIR INSTRUCTIONS 8043 197 Cutting unit Combi 155 ...

Page 107: ...English 106 REPAIR INSTRUCTIONS ...

Page 123: ...English 122 REPAIR INSTRUCTIONS ...

Page 145: ......

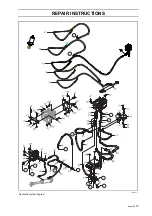

Page 146: ...English 145 APPENDIXES Circuit diagram Circuit diagram 1 ...

Page 147: ...English 146 APPENDIXES Circuit diagram 2 ...

Page 148: ...English 147 APPENDIXES Circuit diagram 3 ...

Page 149: ...English 148 APPENDIXES Circuit diagram 4 ...

Page 150: ...English 149 APPENDIXES Circuit diagram 5 ...

Page 151: ...English 150 APPENDIXES Circuit diagram 6 ...

Page 152: ...English 151 APPENDIXES Circuit diagram 7 ...

Page 153: ...English 152 APPENDIXES Circuit diagram 8 ...

Page 154: ...English 153 APPENDIXES Circuit diagram 9 ...

Page 155: ...English 154 APPENDIXES Circuit diagram 10 ...

Page 156: ...English 155 APPENDIXES Circuit diagram 11 ...

Page 157: ...English 156 APPENDIXES ...

Page 161: ...English 160 APPENDIXES 8043 160 Circuit board placement ...

Page 162: ...English 161 APPENDIXES Hydraulic diagram 8043 247 Hydraulic diagram ...

Page 163: ...English 162 APPENDIXES ...

Page 167: ...2009W18 115 08 30 26 ...