English-

126

TROUBLE SHOOTING

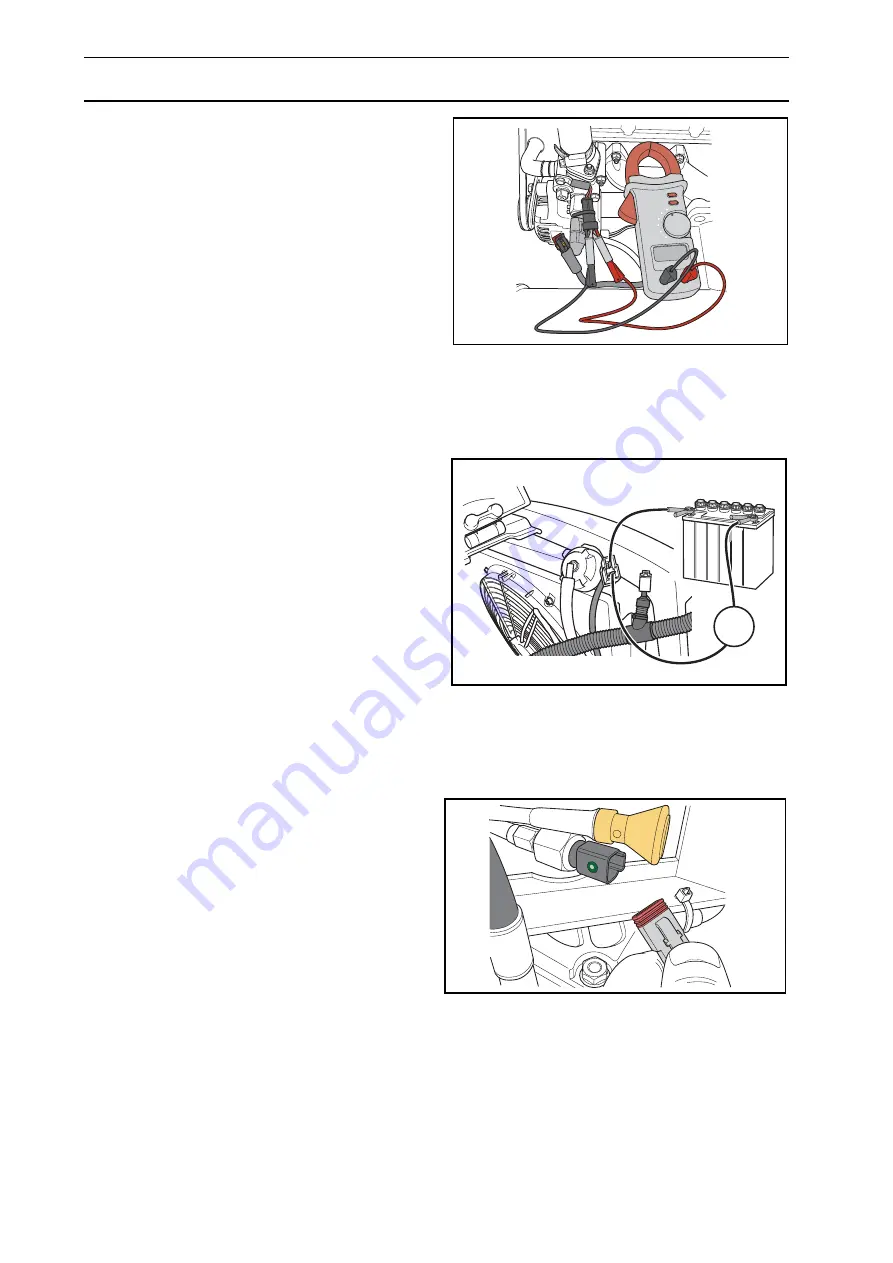

A breakage on the cable between J1 and the

analogue sensor on the thermostat housing

results in theemergency glow plug heating

function activating with a fixed heating time.

Caution: only with an open circuit, if there is

another fault on the sensor so that glow plug

heating does not work the connector can be

disconnected from the sensor and run with

this emergency glow plug heating time. The

time is temperature independent and about

half of the max. time. Check the sensor with

an ohmmeter 0.9 - 1

at room temperature.

With regard to the circuit that activates the

starter motor, proceed in the same way as for

the glow plug heating circuit. A fault in the

glow plug heating circuit can prevent the

starter motor from working. Turn the ignition

key back to glow plug heating and the start

position within 3 seconds. If the starter motor

works, look for the fault in the glow plug heat-

ing circuit.

Cooling fan

A fault in the circuit to the cooling fan's soft

start function can mean that the fan does not

start. Check the cables between the circuit

board and connector on the fan for a short

circuit or open circuit. Now connect an exter-

nal battery to the connector and test run the

fan. Measure the current with an ammeter. If

the fan works normally and the current after

start does not exceed 12 A, replace the cir-

cuit board.

Oil pressure

A short circuited oil pressure sensor means

the engine will stop directly after starting. Dis-

connect the cable from the sensor and test

start. If the engine now starts it is either the

sensor that is malfunctioning or the oil pres-

sure is too low. A sensor with an internal

mechanical fault can cause engine problems,

the engine can stop or run unevenly.

8043-177

Resistance test analogue sensor

A

8043-183

Measuring current to cooling fan

8043-176

Disconnecting oil pressure contact

Summary of Contents for PT 26D

Page 1: ...Workshop manual PT26D English ...

Page 13: ...English 12 SPECIAL TOOLS ...

Page 94: ...English 93 REPAIR INSTRUCTIONS 8043 197 Cutting unit Combi 155 ...

Page 107: ...English 106 REPAIR INSTRUCTIONS ...

Page 123: ...English 122 REPAIR INSTRUCTIONS ...

Page 145: ......

Page 146: ...English 145 APPENDIXES Circuit diagram Circuit diagram 1 ...

Page 147: ...English 146 APPENDIXES Circuit diagram 2 ...

Page 148: ...English 147 APPENDIXES Circuit diagram 3 ...

Page 149: ...English 148 APPENDIXES Circuit diagram 4 ...

Page 150: ...English 149 APPENDIXES Circuit diagram 5 ...

Page 151: ...English 150 APPENDIXES Circuit diagram 6 ...

Page 152: ...English 151 APPENDIXES Circuit diagram 7 ...

Page 153: ...English 152 APPENDIXES Circuit diagram 8 ...

Page 154: ...English 153 APPENDIXES Circuit diagram 9 ...

Page 155: ...English 154 APPENDIXES Circuit diagram 10 ...

Page 156: ...English 155 APPENDIXES Circuit diagram 11 ...

Page 157: ...English 156 APPENDIXES ...

Page 161: ...English 160 APPENDIXES 8043 160 Circuit board placement ...

Page 162: ...English 161 APPENDIXES Hydraulic diagram 8043 247 Hydraulic diagram ...

Page 163: ...English 162 APPENDIXES ...

Page 167: ...2009W18 115 08 30 26 ...