English-

45

DESIGN AND FUNCTION

Hydraulic motor

The hydraulic motor is an inverted gear

motor. The valve disc and gearwheel unit are

located on two levels in the motor. Between

these is a partition wall with drilled holes,

where the oil can flow when they are not cov-

ered by the oscillating rotor. When driving in

one direction, the incoming oil is piped to the

gearwheel unit, which is provided a certain

rotation and power by the oil, via the valve

disc’s outer track. The oil is then piped back

via the valve disc and its inner track out

through the output port.

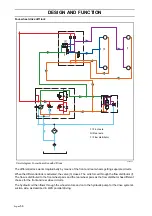

Control unit

The control unit consists of a rotating valve

and a rotating oil gauge. When the operator

turns the wheels, the hydraulic oil is piped

from the control unit via the rotating valve

and the rotating oil gauge to the cylinder port

L(Left) or R(Right), depending on which way

the operator turns the steering wheel. The

rotating oil gauge measures the oil flow to the

control unit in proportion to the steering angle

on the wheels. It is possible to steer the

machine even if there is a breakdown in the

hydraulic pump.

In the control unit is an excess flow valve,

which limits the system pressure to approx.

12 MPa (120 bar).

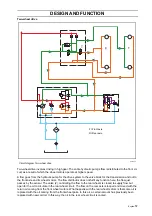

The control unit, which has a type of excess

pressure function, provides the option in

neutral to let the flow go from port P through

the unit and on to port E. The control unit

always prioritises control function and in case

of excess pressure, the control unit permits

the oil to be piped to port E. At full lock all

flow is led through the excess flow valve and

the flow to port E is stopped.

8043-211

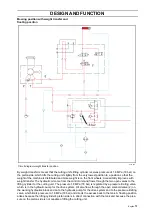

Valve disc

1. Outer track

2. Inner track

8043-210

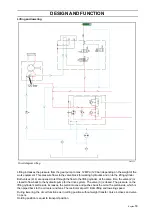

Gearwheel unit

3. Hole to valve disc

4. Roller

5. Rotor

8043-116

Control unit

8043-237

Control unit, diagram

Summary of Contents for PT 26D

Page 1: ...Workshop manual PT26D English ...

Page 13: ...English 12 SPECIAL TOOLS ...

Page 94: ...English 93 REPAIR INSTRUCTIONS 8043 197 Cutting unit Combi 155 ...

Page 107: ...English 106 REPAIR INSTRUCTIONS ...

Page 123: ...English 122 REPAIR INSTRUCTIONS ...

Page 145: ......

Page 146: ...English 145 APPENDIXES Circuit diagram Circuit diagram 1 ...

Page 147: ...English 146 APPENDIXES Circuit diagram 2 ...

Page 148: ...English 147 APPENDIXES Circuit diagram 3 ...

Page 149: ...English 148 APPENDIXES Circuit diagram 4 ...

Page 150: ...English 149 APPENDIXES Circuit diagram 5 ...

Page 151: ...English 150 APPENDIXES Circuit diagram 6 ...

Page 152: ...English 151 APPENDIXES Circuit diagram 7 ...

Page 153: ...English 152 APPENDIXES Circuit diagram 8 ...

Page 154: ...English 153 APPENDIXES Circuit diagram 9 ...

Page 155: ...English 154 APPENDIXES Circuit diagram 10 ...

Page 156: ...English 155 APPENDIXES Circuit diagram 11 ...

Page 157: ...English 156 APPENDIXES ...

Page 161: ...English 160 APPENDIXES 8043 160 Circuit board placement ...

Page 162: ...English 161 APPENDIXES Hydraulic diagram 8043 247 Hydraulic diagram ...

Page 163: ...English 162 APPENDIXES ...

Page 167: ...2009W18 115 08 30 26 ...