1

3

2

LUBRICATION

46

Wheel and Deck Zerks

Use only good quality bearing grease.

Grease from well-known brand names

(petrochemical companies, etc.) usually maintains a

good quality.

Front Wheel Mount

Remove dust cap to expose zerk. Lubricate with a

grease gun until the grease is forced out around the

top washer.

Front Wheel Bearings

Lubricate 3-4 strokes with a grease gun on each set

of wheel bearings.

8065-032

Lubricating front wheels

Cables

If possible, grease both ends of the cables and

move the controls to end stop positions when

lubricating. Refit the rubber covers on the cables

after lubrication. Cables with sheaths will bind if they

are not lubricated regularly. If a cable binds, it can

disrupt operation.

If a cable binds, remove the cable and hang it

vertically. Lubricate it with light engine oil until the oil

begins to escape from the bottom.

8065-036

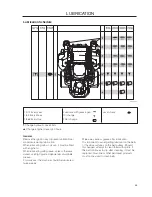

1. Pump filter

2. Oil reservoir

3. Drain port

Changing the hydraulic pump oil and filter

Hydraulic Drive

Fluid and Filter Change

the hydraulic drive is designed with an external

filter for ease of maintenance. to ensure

constant fluid quality levels and longer life, an

oil filter change interval of every 500 hours is

recommended.

the following procedure can be performed with the

pump installed in the vehicle, and the vehicle on

level ground.

1. Lock the vehicle parking brake.

2. Place an oil drain pan with a

2 gallon

capacity

beneath the oil reservoir. Remove the drain

port and drain oil. Remove the oil filter from

the pump.

Drain old oil filters of all free-flowing

oil prior to disposal. Place used oil in

appropriate containers and dispose of it in

accordance with laws in your area.

3. After the oil has drained, wipe the filter base

surface off and apply a film of new oil to the

gasket of the new replacement filter.

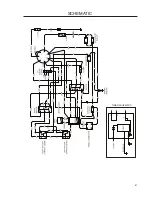

Summary of Contents for PZ 29

Page 51: ...TIMER SCHEMATIC 51 schematic ...

Page 63: ......

Page 64: ...2011 06 14 115 39 45 26 Original instructions ...