Y.5

TE 250 - 310 2012 I.E. / TE 250 - 310 2012 I.E. USA

TC 250 2012 - TC 250 2012 I.E. USA

TXC 250 - 310 2012 I.E. USA

H06832

1

2

3

6

5

4

7

8

9

10 8 13

8

11

12

15

14

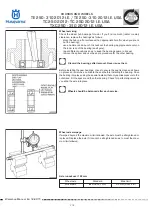

CHASSIS AND WHEELS

Workshop Manual Ed. 12-2011

Front wheel

Legend

1) Tyre

2) Inner tube

3) Rim

4) Spoke

5) Nipple

6) Wheel axle

7) Seal

8) Bearings

9) Hub

10) Spacer

11) Brake Disc

12) Brake disc retaining screw

13) Circlip

14) Outer spacer

15) Pin retaining screw

For technical characteristics regarding the front wheel, see section “A” Gen

-

eral Information of this manual.