6

OPERATION

NOTE:

If at a high altitude (Above 3000 feet) or in cold

temperatures (below 32°F), the carburetor fuel mixture may

need to be adjusted for best engine performance. See “TO

ADJUST CARBURETOR” in the Service and Ad just ments

section of this manual.

TILLING

The most effi cient tillage is obtained when tiller engine is

operated at full throttle. The sound of tiller engine will tell

you when tiller engine is lightly loaded. Raise gauge wheels

to increase tilling depth. If engine seems to be overloaded

or stalls out, lower gauge wheels for shallower tilling.

Operate tiller engine at full throttle and operate tractor in

slowest forward speed, with tractor engine at idle speed or

just above idle. You will soon learn the proper combination

of tilling depth and speed for good tillage.

Soil conditions will determine how deep tiller can penetrate

on the fi rst pass. In extremely hard ground, several passes

may be necessary to till to a depth of 5 inches while in

soft ground, tiller may penetrate to a depth of 5 inches in

the fi rst pass.

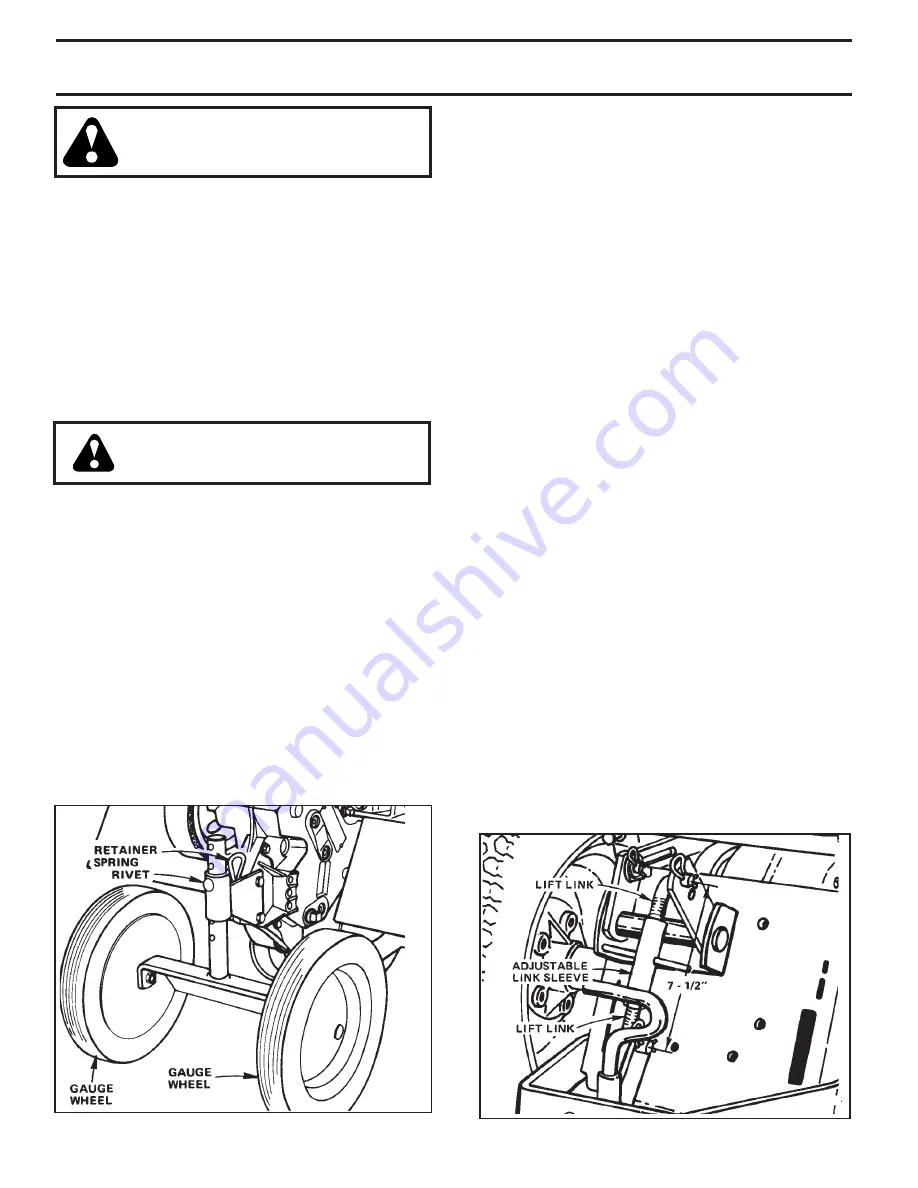

CULTIVATING

Set gauge wheels so that tiller will penetrate soil to a

depth of 2 to 3 inches. Place rivet in the second or third

hole from the bottom to attain this depth. The tiller engine

should be run at full throttle except when cultivating small

plants, a slower engine speed is necessary to prevent

burying the plants.

OPERATION DO’S AND DON’TS

Always dis en gage tine clutch lever (Fig. 3) and stop engine

when traveling to or from fi eld (garden) or when not tilling.

Lift tiller out of the ground when turning corners.

Do not put tractor in reverse gear while tiller is in the ground.

Before leaving tractor seat, stop tractor, shift tractor to

“NEUTRAL” position, throttle down and stop tractor en gine,

set parking brake, remove ignition key and then dis en gage

tine clutch lever, throttle down and stop tiller engine, lower

tiller to ground. Disconnect spark plug.

Disconnect spark plug wires before making any ad just -

ments, repairs or to remove debris in tines.

CAUTION: Fill to bottom of gas tank

fi ller neck. Do not overfi ll. Wipe off any

spilled oil or fuel. Do not store, spill or

use gas o line near an open fl ame.

WARNING:

Experience indicates that alcohol blended fuels

called gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine problems,

the fuel system should be emptied before storage of 30

days or longer. Drain the gas tank, start the engine and

let it run until the fuel lines and carburetor are empty.

Use fresh fuel next season. See Storage sections of this

manual for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

TO START TILLER ENGINE (See Fig. 3)

CAUTION: Keep the tine clutch lever in

“DIS EN GAGED” position when start-

ing engine.

• Make sure spark plug wire is connected to spark plug.

• Move choke control lever to “FULL CHOKE” position

for cold engine start. For warm engine start do not

use choke control.

• Move tiller engine throttle to midway between “FAST”

and “SLOW” positions.

• Grasp starter handle and pull rope out slowly until

engine reaches start of compression cycle (rope will

pull slightly harder at this point).

• Pull rope with a rapid, continuous, full arm stroke. Keep

a fi rm grip on starter handle and let rope rewind slowly.

Do not let starter handle snap back against starter.

• When engine starts, slowly move choke control on

en gine “1/2 CHOKE” position and then to “NO CHOKE”

position as engine warms up.

• Move throttle control to desired running position.

• Allow engine to warm up for a few minutes before

engaging tines.

FIG. 4

FIG. 5