25

Tuff Torq K61 Hydrostatic Transaxle

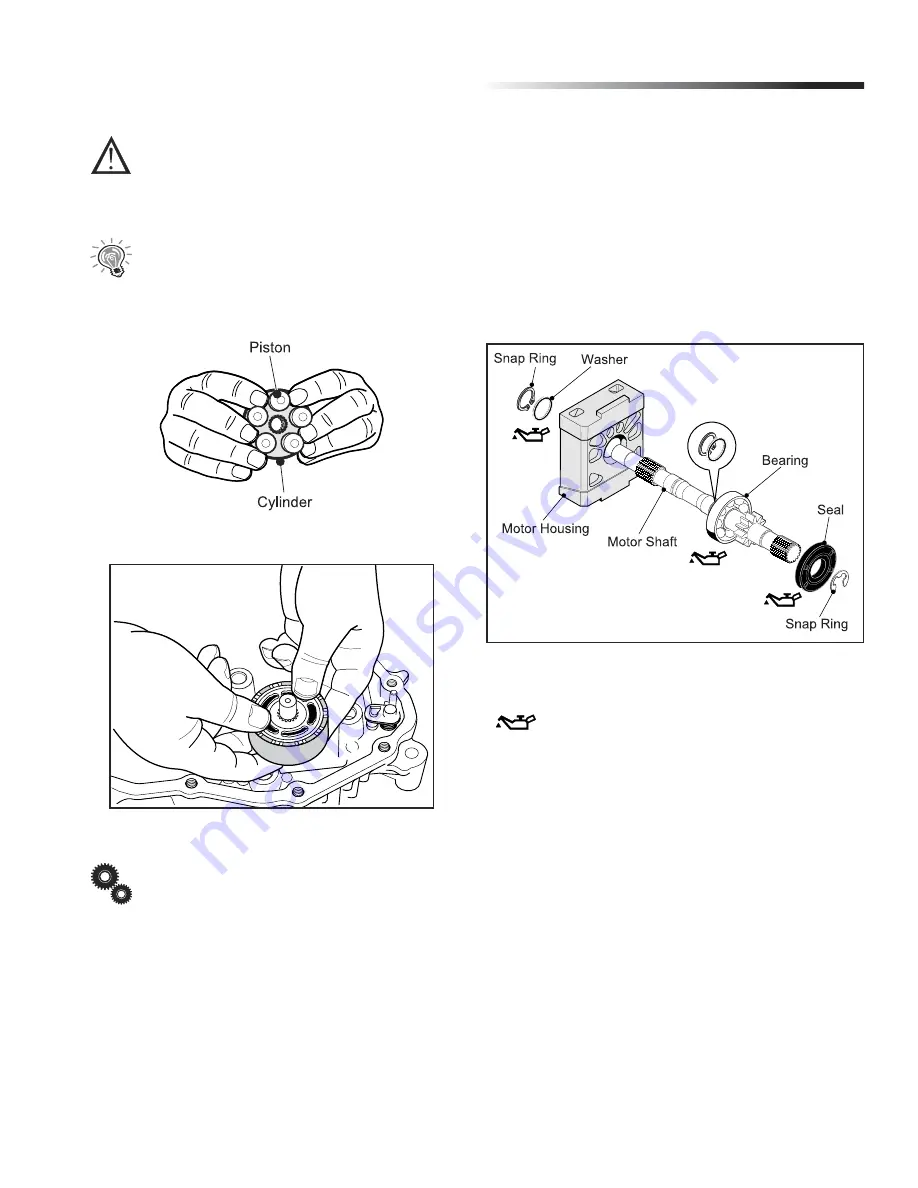

Be careful that the Pistons do not fall out of Cyl-

inder Block. Damage to any component of the assembly

will result in the replacement of the entire assembly.

To avoid the pistons from dropping out during

assembly, position fingers around the cylinder in order

to apply pressure on each of the five pistons. (Fig. 23)

Fig. 23, Finger Placement During Assembly

Fig. 24, Cylinder Block Assembly Installation

If any of the components of Cylinder Block As-

sembly are damaged, they must be replaced with a

complete Cylinder Block Assembly. Individual compo-

nents are not serviced separately.

Motor Shaft Assembly

1. Install a new Bearing onto the Motor Shaft, if required.

2. Lubricate Bearing with clean oil, (old or new).

3. Installation involving a new Bearing:

(Fig. 25)

•

Press Bearing into position.

•

Install Washer.

•

Seat Snap Ring in the Motor Shafts groove.

4. Install a new Seal onto the Motor Shaft.

(Fig. 25)

5. Install Snap Ring in front of new Seal.

(Fig. 25)

Fig. 25, Motor Shaft Assembly

Apply a light coating of grease to the surface

of all Seals and O-rings. Also, apply a small amount of

grease around the mating hole of the Upper Case. For

Bearings and other machined parts, apply a coating of

oil.