8

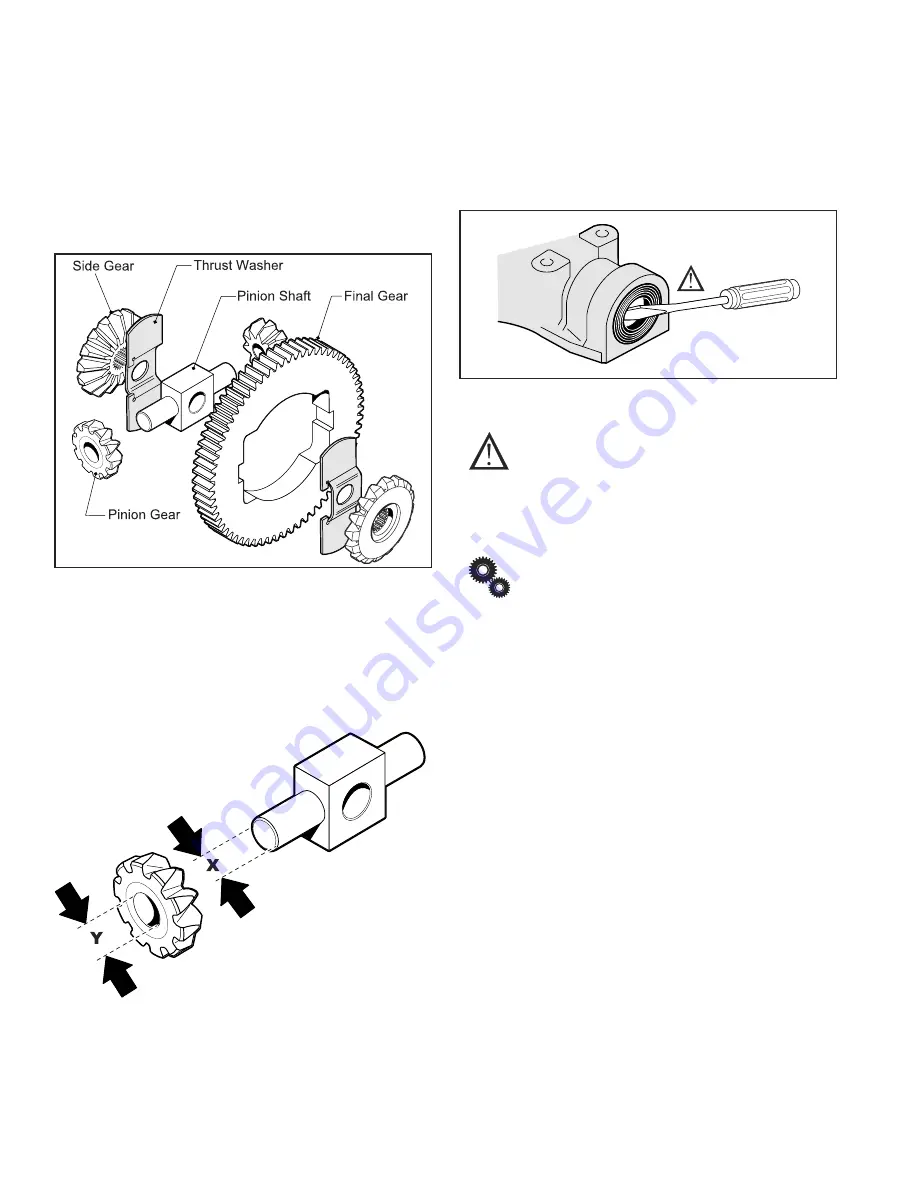

Differential Gear Assembly Removal

1. Remove the Differential Side Gears, Thrust Washers, Dif-

ferential Pinion Gears, and the Differential Pinion Shaft

from the Final Gear.

(Fig. 17)

2. Inspect the Side and Pinion Gears and Pinion Shaft for

scoring, pitting, discoloration and chipped or broken

teeth.

Fig. 17, Differential Gear Assembly

Axle Seal Removal

1. After the Differential Gear Assembly and Axles have

been removed, take out the (2) Axle Seals at each end of

the Upper Case.

(Fig. 19)

Fig. 19, Axle Seal Removal

Extreme caution should be taken when remov-

ing Seals from the Upper Case. Immediately behind

each Axle Seal is a press-fit bushing.

If damaged, the

Upper Case must be replaced, bushings can not be

replaced separately.

Seals should be replaced every time the Axles

are removed.

2. Measure the I. D. (Y) of the Pinion Gears.

(Fig. 18

)

3. If the clearance (Y-X) is

>

0.50 mm (0.019 in), replace the

Pinion Shaft and/or Pinion Gears.

◆

Example of an Unacceptable Tolerance:

Pinion Shaft O. D. (X) = 14.75 mm

Pinion Gear I. D. (Y) = 15.30 mm

Y (15.30 mm) - X (14.75 mm) = 0.55 mm of

clearance. This is

>

the wear limit of 0.50 mm,

replacement is necessary.

Differential Pinion Shaft and Gears Tolerance

1. Using calipers (digital recommended) measure the O. D.

(X) of the Pinion Shaft.

(Fig. 18

)

Fig. 18, Differential Pinion Shaft and Pinion Gears Clearance