18

Before Starting Assembly

Before starting the assembly of the Transaxle check all parts

to ensure that they are clean and free of any foreign

debris, this includes your work area and tools.

Have on hand a new Seal Kit (19215499150). Check contents

of kit for possible defects before installation. Note that

the kit is designed to cover all K61 models. You may or

may not use all the items, in the kit, on your particular

model. The Seal Kit, as well as other parts necessary for

replacement, can be ordered on-line by visiting Tuff

Torq’s Web Site at: www.tufftorq.com (See “Ordering

Replacement Parts”, page ii).

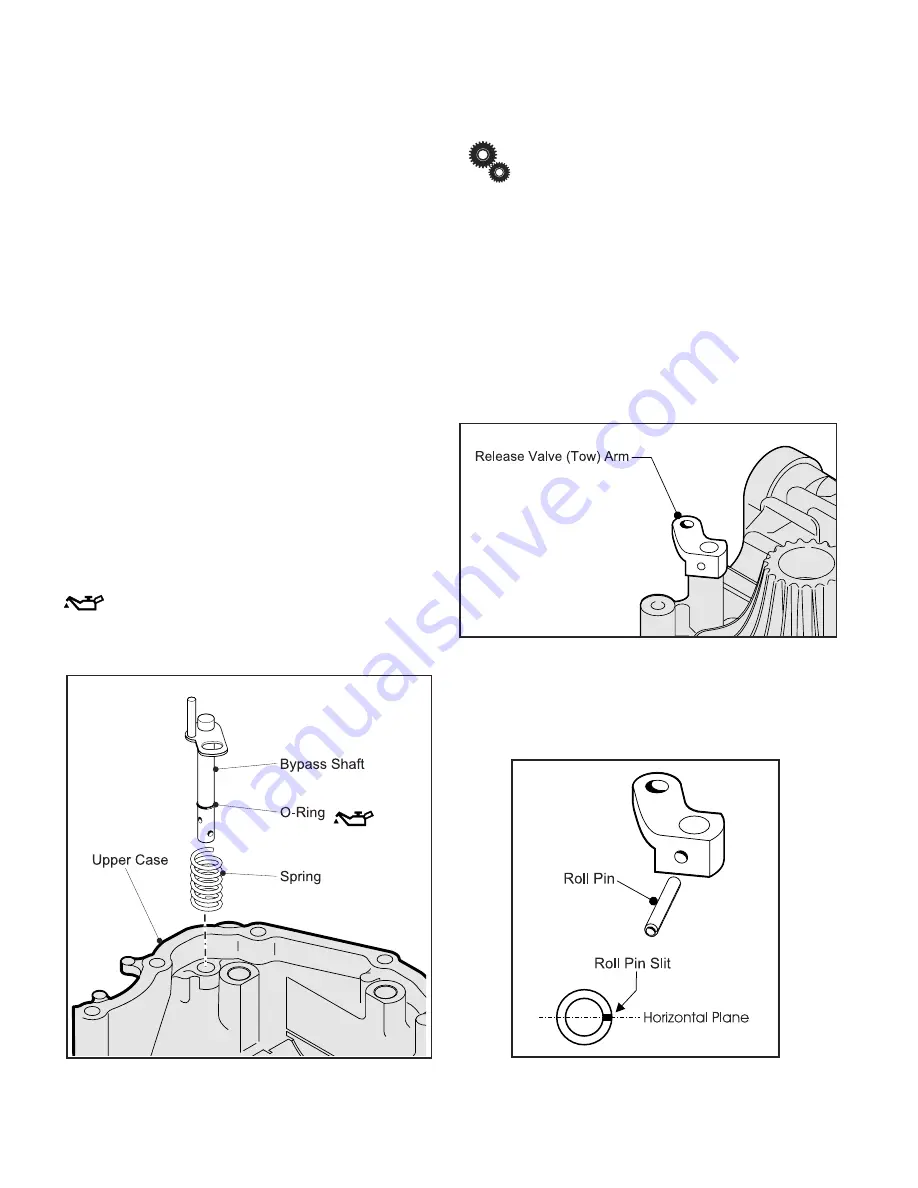

Bypass Shaft Assembly

1. Place the Upper Case on a service stand in the service

position (flange side up).

2. Install a new O-ring onto the Bypass Shaft.

3. Install the Spring onto the Bypass Shaft.

4. Install the Spring and Bypass Shaft into the hole on the

Upper Case.

(Fig. 1)

Apply a light coating of grease to the surface of

the O-ring. Also, apply a small amount of grease into

mating hole of Upper Case.

Fig. 1, Bypass Shaft Assembly

Rather than lubricating packing items (O-rings

and Seals) in advance, apply a light coating of grease

just prior to their installation. This will minimize the pos-

sibility of debris collecting of packing items while wait-

ing to be installed.

5. Since the Bypass Shaft is spring loaded it is recom-

mended that the Release Valve (Tow) Arm be connected

before proceeding.

◆

From the reverse side of the Upper Case, mount the

Release Valve Arm onto the Bypass Shaft; then, align

and secure with Roll Pin.

(Fig. 2)

Fig. 2, Release Valve Arm Assembly

◆

Always install Roll Pins with the slit on a horizontal

plane. This will enable the pin greater holding ability.

Fig. 2a, Roll Pin Installation

Assembly of Transaxle