28 |

Plati num™ Q|160 Quilti ng Machine User’s Guide

(C) Precision

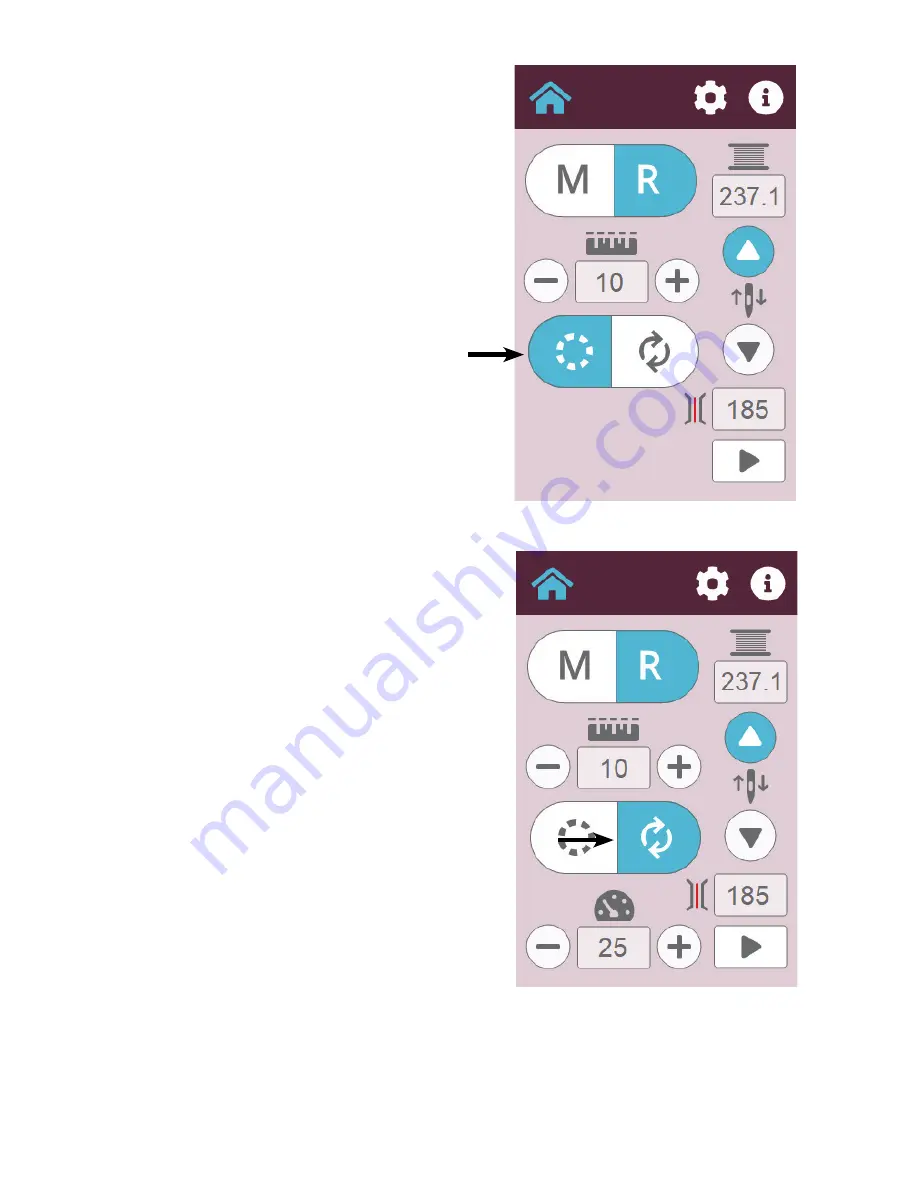

If

Precision

mode is selected, the Plati num™ Q|160 will

not start sti tching unti l fabric moves across the table.

(D) Cruise

If

Cruise

mode is selected, the machine will immediately

begin sti tching at the speed (sti tches per minute)

indicated in the box when the foot pedal is depressed or

the play butt on is selected.

The Cruise speed is the minimum speed the machine

will sti tch, regardless of how slowly the fabric is moving

across the table.

The Cruise speed can be adjusted using the “+” and “-”

butt ons that appear below the Cruise butt on when Cruise

mode is selected. Cruise speed can be adjusted between

50 and 1,100 sti tches per minute.

The

Play/Pause

indicator will change as soon as you

press it or the foot pedal. In

Precision

mode, the needle

will not move unti l the fabric moves across the table. In

Cruise

mode, the needle will sti tch immediately at the

Cruise speed as soon as you press the

Play

butt on or on

the foot pedal.

C

D

Summary of Contents for Viking Platinum Q 160

Page 1: ...User s Guide KEEPING THE WORLD SEWING 60 Stationary Machine ...

Page 2: ......

Page 4: ......

Page 48: ... 44 Platinum Q 160 Quilting Machine User s Guide ...

Page 50: ......

Page 51: ......

Page 52: ...www husqvarnaviking com 4710610 26A 2020 KSIN Luxembourg II S a r l All rights reserved ...