31

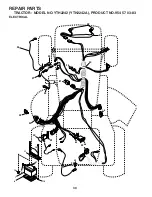

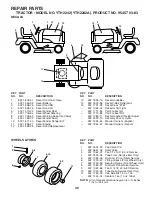

REPAIR PARTS

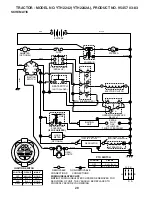

TRACTOR - MODEL NO. YTH2242 (YTH2242A), PRODUCT NO. 954 57 03-83

ELECTRICAL

KEY PART

NO. NO. DESCRIPTION

1 532 14 49-27 Battery

2 874 76 04-12 Bolt Hex Hd 1/4-20unc X 3/4

8 532 12 48-86 Tray Battery

10 532 14 52-11 Bolt Brt Frt 1/4-20 x 75 Ainc

11 532 15 01-09 Holddown Battery Front Mount

12 532 14 57-69 Nut Push Nylon 1/4" Battery Frt

16 532 17 61-38 Switch Interlock Push-In

21 532 17 56-88 Harness Asm Light W/4152j

22 532 00 41-52 Bulb Light #1156

24

532 17 89-09

Cable Battery 6 Ga 22" red w/16 wire

25 532 12 47-80 Cable Battery 6 Ga 11" red

26 532 17 51-58 Fuse

27

873 03 08-00

Nut Flange, M8 x 1.25

28 532 14 54-91 Cable Ground 6 Ga 21" black

29 532 16 07-84 Switch Plunger Nc Gray

30 532 17 55-66 Switch Ign

33 532 14 04-01 Key Ign Molded Generic

40 532 17 97-24 Harness Ign.

42

532 15 43-36

Cover, Terminal, Red

46 532 16 96-35 Meter Hour

48 532 14 08-44 Adapter Ammeter

50 532 17 46-51 Switch PTO

51 532 14 04-05 Ring Retainer PTO

55 817 49 05-08 Screw Thdrol 5/16-18 x 1-1/2 Tyt

81 532 10 97-48 Relay Asm.

89 532 16 96-39 Bracket Snap-In Hourmeter

NOTE:

All component dimensions given in U.S. inches.

1 inch = 25.4 mm.

Summary of Contents for YTH2242 TF

Page 1: ...02494 YTH2242 Owner s Manual ...

Page 44: ...44 SERVICE NOTES ...

Page 45: ...45 SERVICE NOTES ...

Page 48: ...532 18 54 46 Rev 1 1 3 03 RD Printed in U S A ...