3

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

• Be sure the area is clear of bystanders before operat-

ing. Stop machine if anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary.

Al ways look down and behind before and while back-

ing.

•

Never carry children, even with the blades shut off. They

may fall off and be seriously injured or interfere with

safe machine operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over

by the machine.

•

Keep children out of the mowing area and in the watchful

care of a responsible adult other than the operator.

• Be alert and turn machine off if a child enters the

area.

• Before and while backing, look behind and down for

small children.

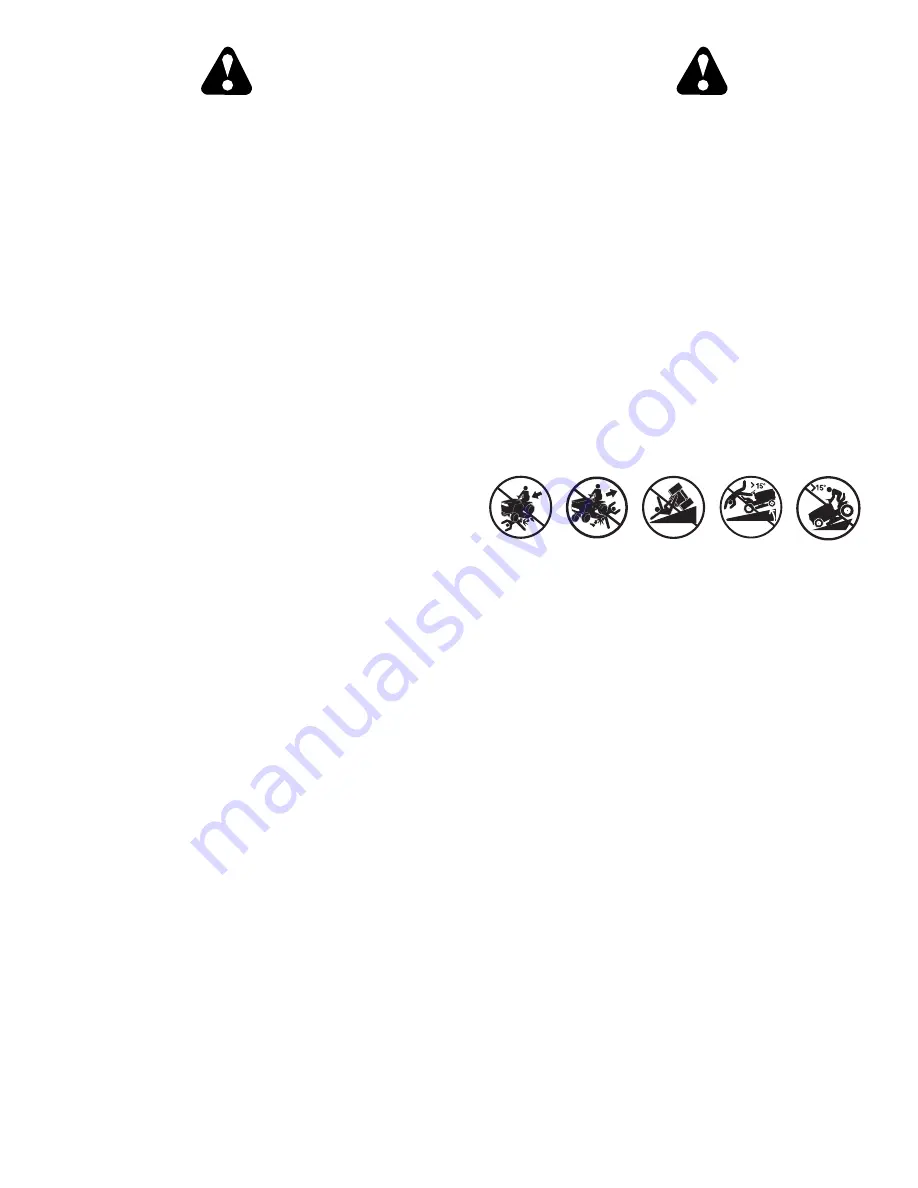

• Mow up and down slopes (15° Max), not across.

• Choose a low ground speed so that you will not have

to stop or shift while on the slope.

• Avoid starting, stopping, or turning on a slope. If the

tires lose traction, disengage the blades and proceed

slowly straight down the slope.

•

If machine stops while going uphill, disengage blades,

shift into reverse and back down slowly.

•

Do not turn on slopes unless necessary, and then, turn

slowly and gradually downhill, if possible.

III. CHILDREN

Tragic accidents can occur if the operator is not alert to

the presence of children. Children are often attracted to

the ma chine and the mowing activity. Never assume that

children will remain where you last saw them.

•

Keep children out of the mowing area and in the watchful

care of a responsible adult other than the operator.

• Be alert and turn machine off if a child enters the

area.

• Before and while backing, look behind and down for

small children.

•

Never carry children, even with the blades shut off. They

may fall off and be seriously injured or interfere with

safe machine operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over

by the machine.

• Never allow children to operate the machine.

•

Use extra care when approaching blind corners, shrubs,

trees, or other objects that may block your view of a

child.

IV. TOWING

• Tow only with a machine that has a hitch designed for

towing. Do not attach towed equipment except at the

hitch point.

•

Follow the manufacturer's recommendation for weight

limits for towed equipment and towing on slopes.

• Never allow children or others in or on towed

equipment.

• On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

• Travel slowly and allow extra distance to stop.

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property damage, use extreme

care in handling gasoline. Gasoline is extremely flammable

and the vapors are explosive.

• Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

• Use only approved gasoline container.

• Never remove gas cap or add fuel with the engine

running. Allow engine to cool before refueling.

• Never fuel the machine indoors.

•

Never store the machine or fuel container where there

is an open flame, spark, or pilot light such as on a water

heater or other appliances.

• Never fill containers inside a vehicle or on a truck or

trailer bed with plastic liner. Always place containers

on the ground away from your vehicle when filling.

• Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment with a portable container,

rather than from a gasoline dispenser nozzle.

•

Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete.

Do not use a nozzle lock-open device.

• If fuel is spilled on clothing, change clothing immedi-

ately.

• Never overfill fuel tank. Replace gas cap and tighten

securely.

GENERAL SERVICE

• Never operate machine in a closed area.

• Keep all nuts and bolts tight to be sure the equipment

is in safe working condition.

• Never tamper with safety devices. Check their proper

operation regularly.

• Keep machine free of grass, leaves, or other debris

build-up. Clean oil or fuel spillage and remove any fuel-

soaked debris. Allow machine to cool before storing.

• If you strike a foreign object, stop and inspect the

machine. Repair, if necessary, before restarting.

•

Never make any adjustments or repairs with the engine

run ning.

• Check grass catcher components and the discharge

chute frequently and replace with manufacturer's rec-

ommended parts, when necessary.

• Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing them.

•

Check brake operation frequently. Adjust and service

as required.

• Maintain or replace safety and instruction labels, as

necessary.