English-

43

MAINTENANCE

Checking the Parking Brake

Visually check that no damage is found on

the lever, links, or switch belonging to the

parking brake. Perform a stand-still test and

check that there is sufficent braking action.

To adjust the parking brake, contact the

Husqvarna service workshop.

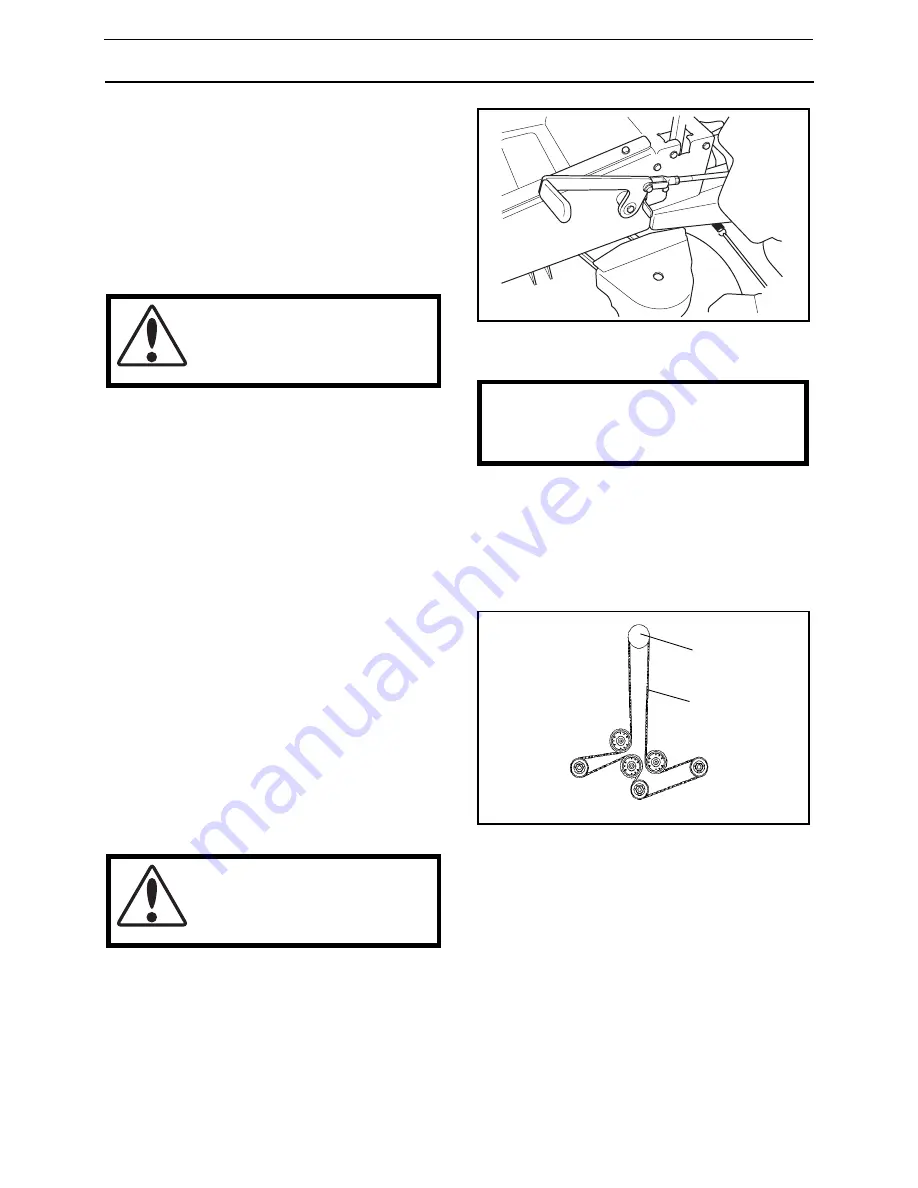

Checking the V-belts

Check every 100 hours of operation. Check

for severe cracking and large nicks.

NOTE: The belt will show some small cracks

in normal operation.

The belts are not adjusable. Replace belts if

they begin to slip from wear.

Deck belt

To replace deck belt

Deck belt removal.

•

Park on a level surface. Apply park

brake.

•

Lower the deck into the lowest cutting

position.

•

Disengage the tension relief lever from

the lock bracket.

•

Remove screws from both the left and

right belt shields, and remove shields.

•

Remove any dirt or grass that may have

accumulated around the cutter housings

and entire deck surface.

8011-711

The parking brake in the disengaged position

IMPORTANT INFORMATION

The maschine must be absolutely stand

still when applying the parking brake.

WARNING!

Faulty adjustment can cause

an accident.

8011-764

1. Clutch pulley

2. Deck belt

Belt routing, deck belt

1

2

WARNING!

Lever is spring loaded. Have a

tight grip on the lever and

release slowly.