12

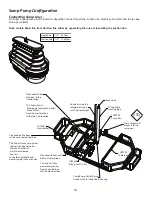

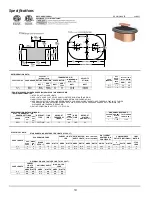

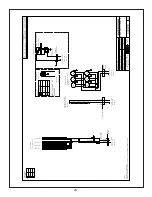

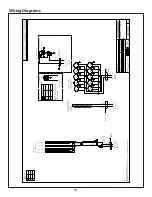

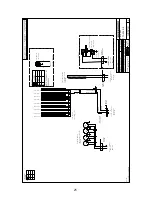

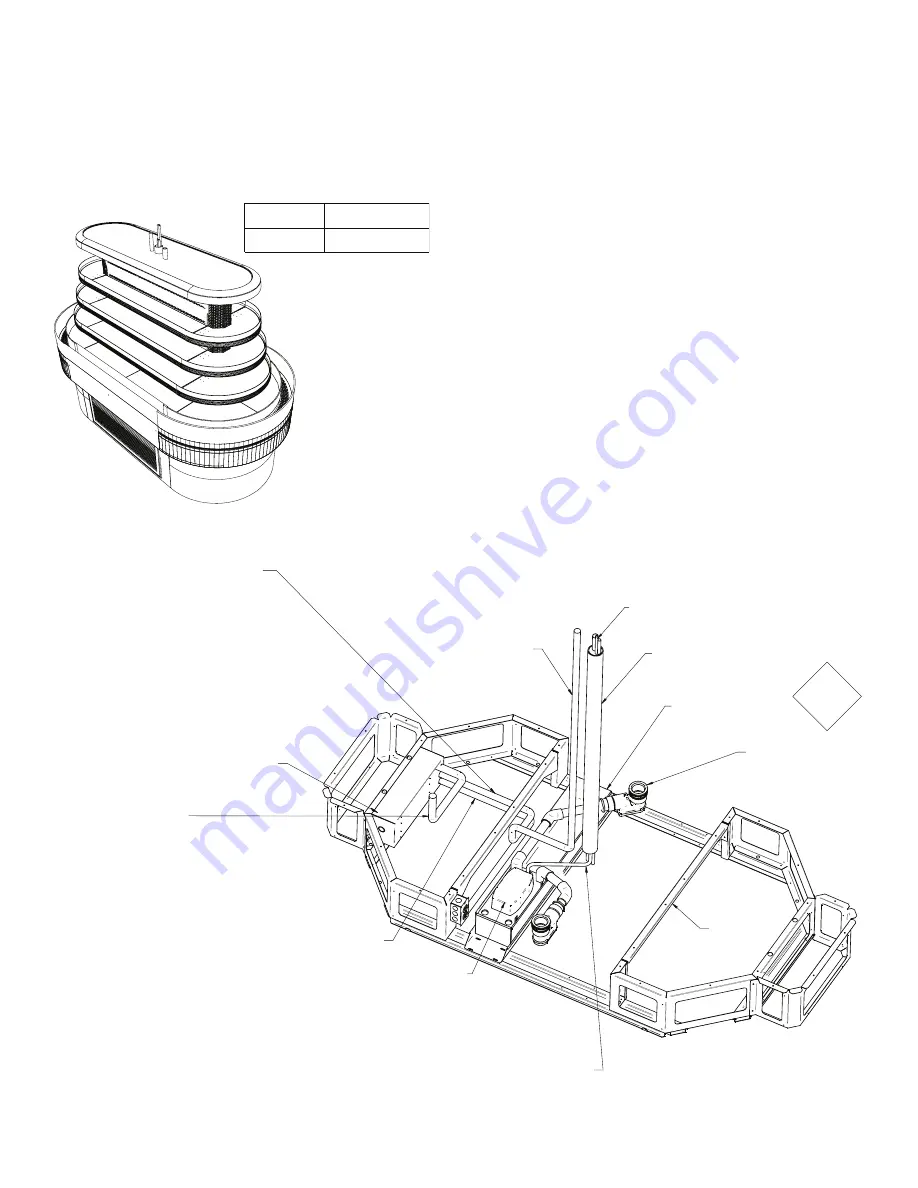

Flex conduit from

elec. box to top

stub location.

This line will carry

-Main power and ground wires

-Sensor Wires

from the electrical box

to the top stub location.

Conduit inside the

refrigerated zone

must be liquid tight.

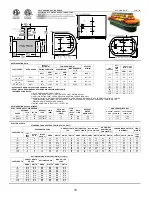

TY Top Mech

Housing Pipe

1H79952

Sump Pan

Drain spigots will

empty into the

sump pan

1H79925

Tub Brace

Sump Pump Outlet Piping

Connect to 3/8” drain linein housing

1H22638

(Diversitech CP-22)

Flex conduit from outlet

box to electrical box

This line will carry

power and ground

from the outlet box

the the electrical box.

Flex conduit line from

inside case to electrical box

This line will carry wiring from

-shelves/Canopy Harnesses

-Main Fan Harnesses

-Anti-Sweat Heaters

-Sensors

to the terminal block and

power supply in the elec. box.

1H79961

Electrical Box

Check Valve

CTQ

Sump Pump Configuration

Connecting Sump Lines

For Entyce cases with a Sump Pump Configuration connect liquid line, suction line, electrical, and drain line to top case

stub-ups (outlets).

Note: Isolate Drain line from Suction line either by seperating the lines or insulating the suction line.

Liquid Line 1/2” 85 fpm

Suction Line 7/8” 1234 fpm