Rev. 0308

11

Note: to scroll down the parameters without changing

them, press the DOWN button.

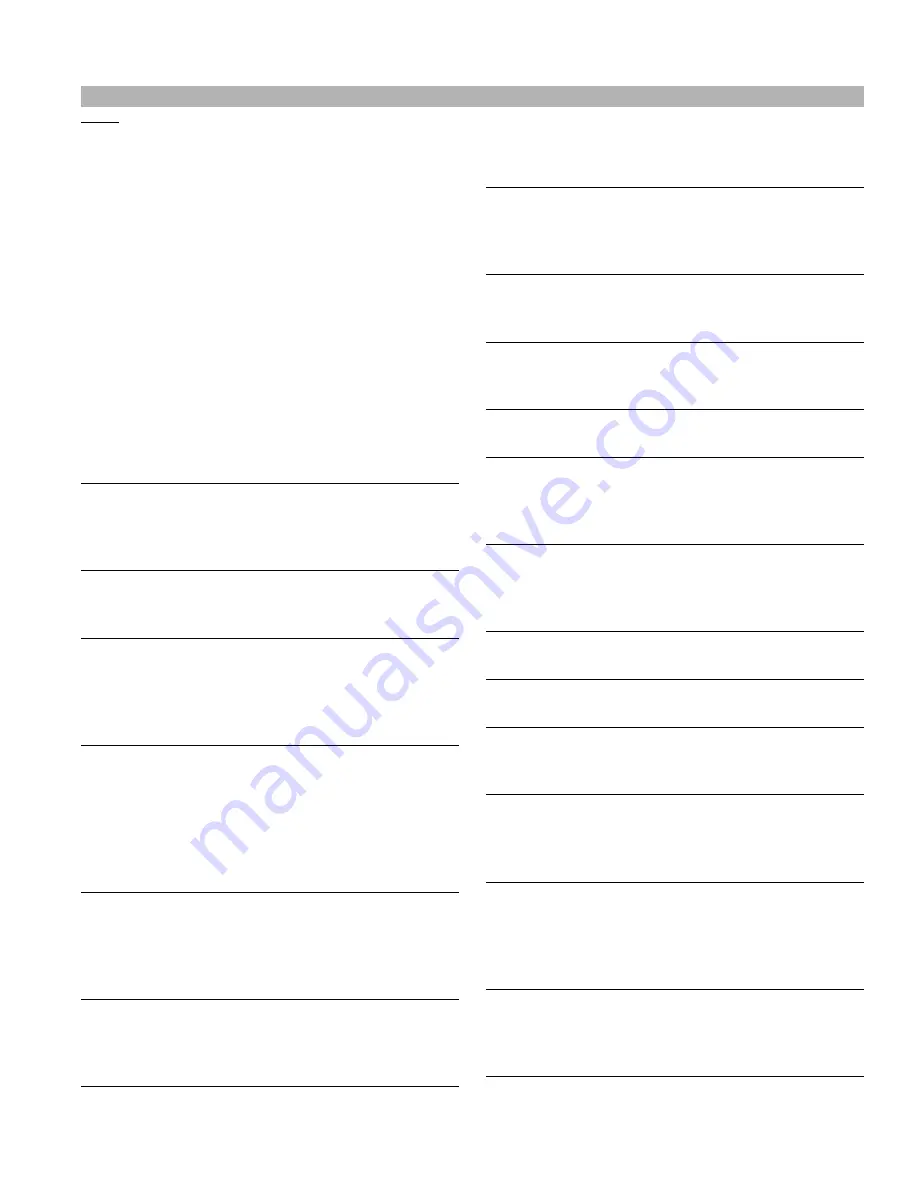

List of Parameters

Here is a list of the parameters that can be changed in

the Second Level of programming, as well as their

options and ranges.

Parameter/Display Symbol Description Range / Options

Display Status

dSPL

Information shown on

the display during operation

conditions

tdAy – time-of-day

rSP° – zone temperature

(refrigerated space)

CyCL – cycle between time

and zonetemperature

Epr° – evaporator coi

temperature

Clock Format

CLHr

Format of the time (12

or 24 hours mode)

12Hr – AM/PM format

24Hr – 24 hour format

TemperatureFormat °dSPTemperature degrees °F –

degrees Fahrenheit°C – degrees

Celsius

Defrost Type

dFtP

Type of defrost used in

the application

ELEC – electric heater defrost / off

cycle

HgAS – hot gas–

Fan Status During Defrost

EFAN

Enable or not the fan

during defrost

no – fan is turned off during

defrost

yES – fan remains on during

defrost

Defrost Interval

dFin Type of defrost interval

TdAy – time-of-day setpoint

CPrn – compressor run time

tdEF–– temperature initiated

defrost

Minimum Compressor Off Time

CoFF

Minimum time that the

compressor will remain turned off

Range: from 0 to 15 min

Minimum Compressor On Time

Con Minimum time that the

compressor will remain turned on

Range: from 0 to 15 min

Alarm Delay

ALrd

Time delay before the

alarm goes off after the

temperature fall off the two alarm

setpoints Range: from 0 to 59 min

Compressor Run Time

CPrn

Time the compressor

will run between defrosts

Number of Defrosts nodF

Number of defrosts per

day

from 0 to 8 (0 means 1 defrost

every 48 hours)

Defrost Start Time

dEF1-8

Start time of each

defrost

Defrost Duration

dEFd

Defrost duration time

(back-up for defrost termination

temperature) Range: from 0 min

to 4 hours

Fan Delay FAnd

Delay time for the fan after defrost

(back-up for fan cut-in

temperature) Range: from 0 to 15

min

Pump Down

Pudn

Pump down duration

Range: from 0 to 59 min

Drip Time driP

Drip time duration Range: from 0 to

59 min

Setpoint Differential diF° Cut-in temperature

differential Note: cut-in is cut-out

plus differentialRange: from 1 to 25°

Temperature Initiated Defrost

tdEF

Temperature

that will initiate a defrost cycle

Range: from – 40 to 40°F or–– 40 to

4°C

Defrost Termination Temperature

dEF°

Temperature in the evaporator that

will terminate the defrost cycle

Range: from 0 to 75°F or –18 to

25°C

Fan Cut-In Temperature

FAn°

Temperature in the

evaporator that will turn the fan on

after defrost

Range: from – 40 to

60°F or–– 40 to 23°C

Paragon ERC 2 Electronic Controller for Self Contained Cases Cont’d