H1 Self Contained glass front multideck

Installation manual

________________________________________________________________________________________________________________________

Hussmann

Page

14

Appendix 3

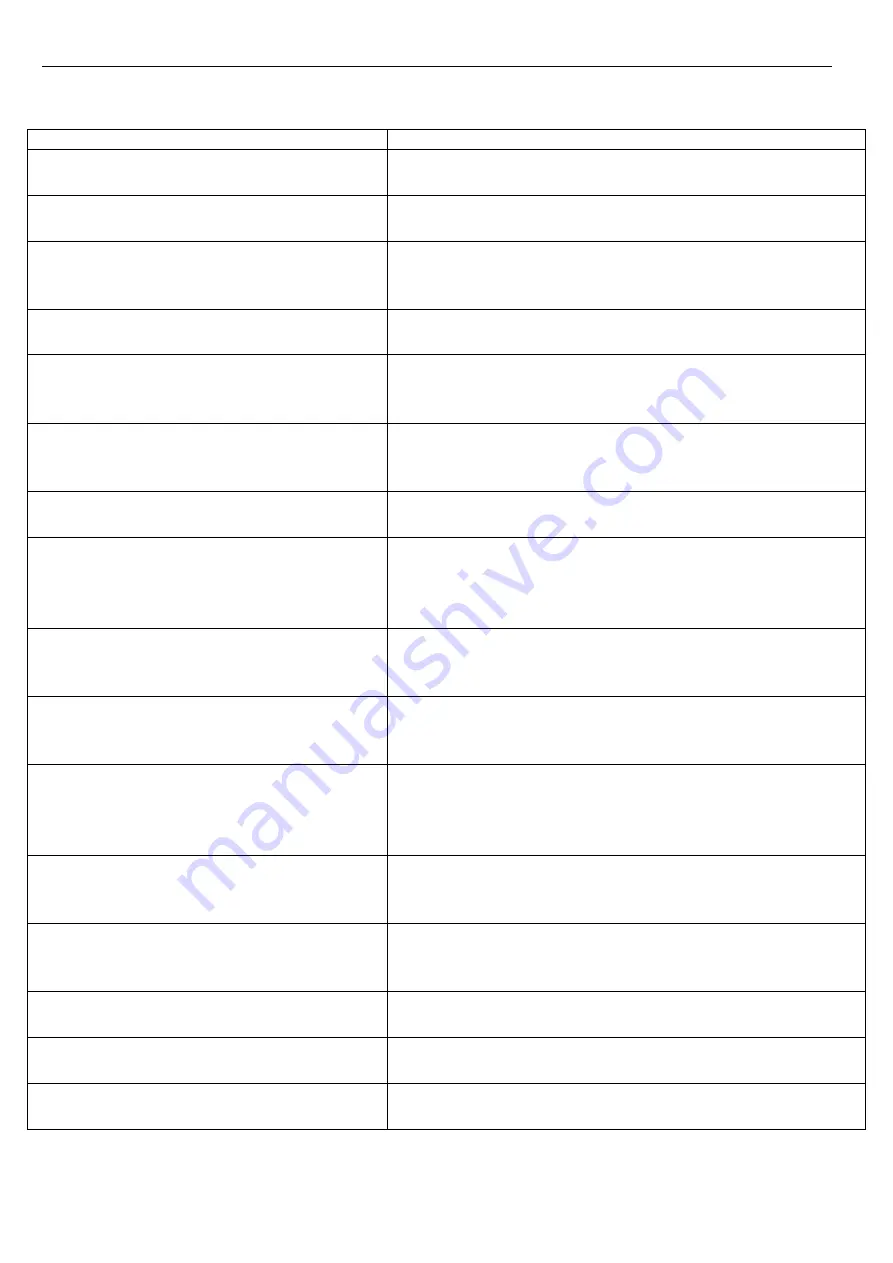

Risk analysis

Hazard

Control Measures

Electrical -

Replacement of electrical components

Request a service call. Electrically isolate cases before works

Ergonomic -

Moving/ positioning/ adjusting cases

Staff must be trained in the correct procedures for setting up cases

and ergonomic practices. PPE must be worn

Falling -

Checking wiring during servicing

Use of barriers & fall arrest systems as appropriate & in accordance

with State & Territory Legislation. Safe working at heights

Entanglement -

Contact with fans when cleaning

Electrically isolate cases before work is carried out. Staff training,

Cuts and stabbing -

Potential for cuts from broken fluorescent tube or

during tube replacement

Electrically isolate cases. Staff not to replace tubes. Call service

provider. PPE must be worn.

Electrical -

Potential for electric shock when cleaning electrical

fittings and components

Electrically isolate cases before work is carried out. Staff training,

RCD. Keep electrical connections dry at all times.

Falling -

Climbing on shelves

Staff must be trained in OH&S procedures. MUST not climb on

shelves or cases.

Crushing -

Hands or fingers may become pinched or crushed

during the positioning of base trays, shelves &

stock

Staff must be trained in the correct procedures for setting up

cases and ergonomic practices

Slipping -

Drain may leak or become blocked causing water

spillage

Visual Inspection and regular maintenance. Request service call

when necessary.

Cuts and stabbing -

Potential for cuts caused by damaged or missing

parts

Visual Inspection and regular maintenance. Request service call

when necessary. PPE must be worn when handling broken or

damaged parts.

Ergonomic -

Stretching during the cleaning of the case and

positioning of stock and shelves leading to strains

and sprains

Staff must be trained in the correct procedures for cleaning cases &

ergonomic practices. Cleaning tools which reduce the need for

stretching should be used.

Slipping -

Surfaces may become slippery due to spillage from

the case during operation or cleaning

Visual Inspection. Appropriate remedial action.

Cuts and stabbing -

Potential for cuts caused by sharp edges &

evaporator coil during cleaning

PPE must be worn by staff

Cuts and stabbing -

Cleaning cold glass surfaces with hot water

Staff must be trained in the correct procedures for cleaning cases

and ergonomic practices

Crushing -

fingers, hands or body between product trays

Operators to always lift product trays using finger pulls provided,

ensuring the area is clear of other persons.

Electrical -

electrical connections in cases

Electrically isolate cases before work begins. Must be carried out by

a service provider. Staff training.

Table 2 Risk analysis