Rev. 0508

7

Electrical Service Receptacles (When Applicable)

The receptacles located on the exterior of the merchandiser

are intended for scales and lighted displays. They are not

intended nor suitable for large motors or other external

appliances.

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters

Thermostats, and Lights.

Field Wiring and Serial plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specified. Field wiring from the refrigeration control panel to

the merchandisers is required for refrigeration thermostats.

Most component amperes are listed in the “Case Specs”

section, but always check the serial plate.

Ballast Location

Ballasts are located within the access panel that runs the

length of the rear of the case. Refer to diagram on page 6.

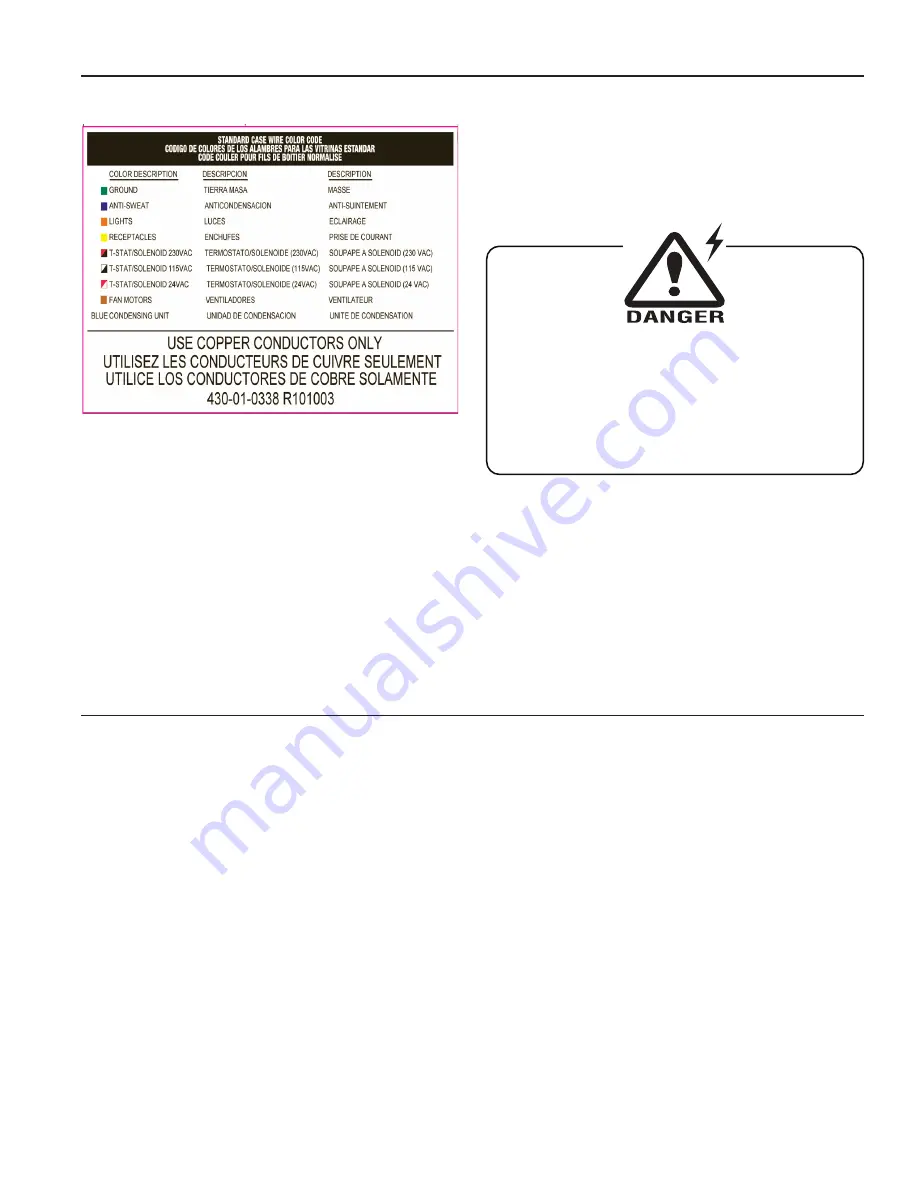

Electrical

Wiring Color Code

CASE MUST BE GROUNDED

NOTE: Refer to label illustrated above that is affixed to case

to determine the actual configuration as checked in the

“TYpE INSTALLED” boxes.

Electrical Circuit Identification

Standard lighting for all models will be full length fluorescent

lamps located within the case at the top.

The switch controlling the lights, the plug provided for

digital scale, and the thermometer are located at the rear

of the case mullion.

The receptacle that is provided on the exterior back of these

models is intended for computerized scales with a five amp

maximum load, not for large motors or other high wattage

appliances. It should be wired to a dedicated circuit.

Finishing Touches

plexiglass Joining Instructions

Note:

All cases in a line up are set, leveled and joined together

in the factory to ensure proper alignment and tight joints

between the cases. To obtain equally tight joints between

cases, it is critical to use the GE 1200 silicone (supplied

with cases) for sealing case joints. Only the use of

silicone allows case joints to pull up tight! DO NOT USE

pERMAGUM! Use of permagum will cause large gaps at

case joints.

parts List

• 1” Plastic rod 3/16” diameter

• Acrylic Solvent Cement (IPS weldon #40 or

comparable)

• Masking tape and duct tape (not supplied)

Instructions

1. Prepare front plexiglass for cement application by

placing masking tape, a maximum 1/16 of an inch

from the seam, on both sides front and back. Tape is

to protect plexiglass from cement spill over. Scarring

will occur if cement touches clear plexiglass.

. Separate front plexiglass pieces enough to apply a

bead of #40 cement down one edge inside of seam

and plastic rod area.

3. Realign front plexiglass and push together tightly.

Insert the plastic rod until flush with top of plexiglass.

4. Apply tape (” duct tape recommended) across

face of seam to secure plexiglass from shifting while

cement dries (approximately 1 hour).

5. With a little silicone, attach the plex clip over the joint

in the glass.

Weldon #40 (2-part) Cement - Mixing Instructions

1. Bring Parts “A” and “B” to room temperature before

mixing.

. Add Part “A” to Part “B”. They have been

premeasured at the factory.

3. Stir slowly and evenly, as to avoid air bubbles. Mix for

1-3 minutes.