Rev.0105

5

Refrigeration

REFRIGERANT TYPE

The standard refrigerant will be R-22 unless otherwise

specified on the customer order. Check the serial plate

on the case for information.

PIPING

The refrigerant line outlets are located under the case.

Locate first the electrical box, the outlets are then on

the same side of the case but at the opposite end.

Insulate suction lines to prevent condensation drippage.

REFRIGERATION LINES

LIQUID

SUCTION

3/8" O.D.

5/8" O.D.

NOTE: The standard coil is piped at 5/8" (suction); however,

the store tie-in may vary depending on the number of

coils and the draw the case has. Depending on the case

setup, the connecting point in the store may be

5

/

8

",

7

/

8

", or 1

1

/

8

". Refer to the particular case you are

hooking up.

Refrigerant lines should be sized as shown on the

refrigeration legend furnished by the store.

Install

P-traps

(oil traps) at the base of all suction line

vertical risers.

Pressure drop

can rob the system of capacity. To keep the

pressure drop to a minimum, keep refrigerant line run

as short as possible, using the minimum number of

elbows. Where elbows are required, use long radius

elbows only.

CONTROL SETTINGS

See the “Case Specs” section of this guidebook for the

appropriate settings for your merchandiser. Maintain

these parameters to achieve near constant product

temperatures. Product temperature should be mea-

sured first thing in the morning, after having been

refrigerated overnight. For all multiplexing, defrost

should be time terminated. Defrost times should as

directed in the Case Specifications section of this guide.

The number of defrosts per day should never change.

The duration of the defrost cycle may be adjusted to

meet conditions present at your location.

ACCESS TO TX VALVES & DRAIN LINES

MECHANICAL

- Remove product from left end of case.

Remove product racks. Remove refrigeration and drain

access panels (labeled). TX valve (mechanical only) and

drain are located under each access panel at end of the

case.

ELECTRONIC

- The Electronic Expansion valve control-

ler is located within the electrical access panel(s)

(Remote models only).

ELECTRONIC EXPANSION VALVE

(OPTIONAL)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and

controller manufacturers information sheet. Sensors

for electronic expansion valves will be installed on the

coil inlet, coil outlet, and in the discharge air. (Some

supermarkets require a 4th sensor in the return air).

Case controllers will be located in the electrical race-

way or under the case

THERMOSTATIC EXPANSION VALVE LOCATION

This device is located on the same side as the refrigera-

tion stub. An Alco balanced port expansion valve model

is furnished as standard equipment, unless otherwise

specified by customer.

EXPANSION VALVE ADJUSTMENT

Expansion valves must be adjusted to fully feed the

evaporator. Before attempting any adjustments, make

sure the evaporator is either clear or very lightly

covered with frost, and that the fixture is within 10

°

F of

its expected operating temperature.

MEASURING THE OPERATING SUPERHEAT

1. Determine the suction pressure with an accurate

pressure gauge at the evaporator outlet.

2. From a refrigerant pressure temperature chart,

determine the saturation temperature at the

observed suction pressure.

3. Measure the temperature of the suction gas at the

thermostatic remote bulb location.

4. Subtract the saturation temperature obtained in step

No. 2 from the temperature measured in step No. 3.

3. The difference is superheat.

5. Set the superheat for 5

°

F - 7

°

F.

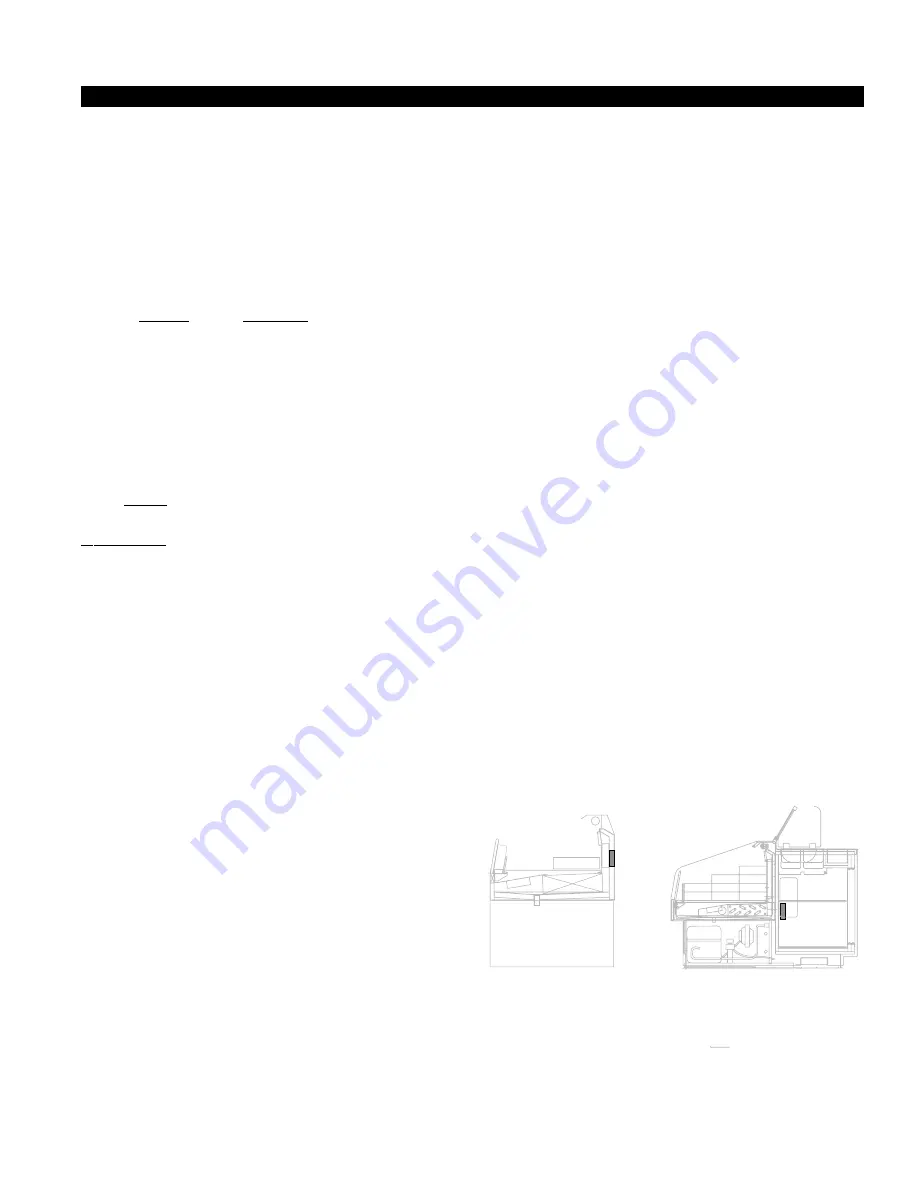

T-STAT LOCATION

T-Stats are located within the electrical raceway. Refer

to diagram below.

Optional

Light

RCD - Remote

Shown with Options

Scale = 3/4"

T Stat

RCD - SC

Shown with Refrigerated Rear Storage

Scale = 3/4"

T Stat

COIL