Rev.0105

9

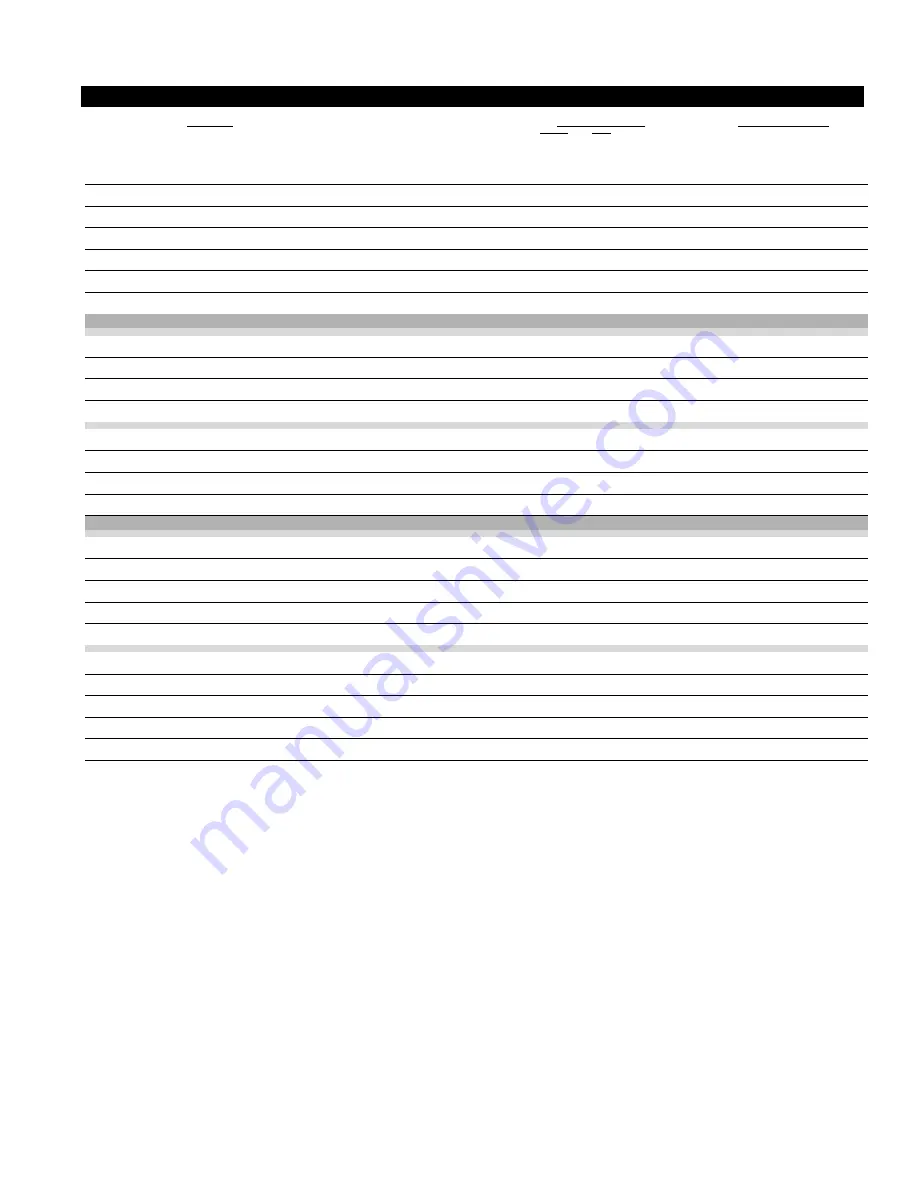

TEMPERATURE

DISCHG.

TYPE

FAN SIZE

DEFROST

115 V. ELECTRICAL CIRCUITS

SELF CONTAINED UNIT DATA

LENGTH

BTU

AVG

AIR

T-STAT/

&

&

FREQ.

CIRCUIT 1

CIRC. 2

SELF CONTAINED

REQ’D

EVAP

PROD

DISC

VELOC

CUT IN

MAKE

NUMBER

&

E E FANS

STD.

Lights

LOW PRESSURE

APPLICATION

PER FT.

TMP

TMP

TMP

@FPM

SETTINGS

EVAP. COIL

OF MOTORS

DURATION

(OPTIONAL)

FANS

(Opt)

CONTROL & SETTINGS

H.P.

VOLTS

AMPACITY

RCD

3'

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.18

.33

50# In /

1/3

115

10.9

Air

Axial

-

-

-

-

30# Out

4'

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.18

-

50# In /

1/3

115

10.9

Air

Axial

-

-

-

-

30# Out

5'

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.18

-

50# In /

1/2

115

18.1

Air

Axial

30# Out

6'

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.36

-

50# In /

3/4

208/230

8.7

Air

Axial

-

-

30# Out

8’

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.54

-

50# In /

1

208/230

13.0

Air

Axial

-

-

30# Out

10’

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.54

-

50# In /

1

208/230

13.0

Air

Axial

-

-

30# Out

12’

820

20

°

38

°

30

°

125

30

°

Forced

4 1/2"

40 (3)

N/A

.54

-

50# In /

1 1/2

208/230

19.0

Air

Axial

-

-

30# Out

Rear Storages - Refrigerated by Mullion Coils

12” Deep

4'

125

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

.54

Air

(3)

(3)

6'

125

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

.72

Air

(4)

(3)

8'

125

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

1.08

Air

(6)

(3)

12'

125

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

1.44

Air

(8)

(3)

16” Deep

4'

175

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

.54

Air

(3)

(3)

6'

175

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

.72

Air

(4)

(3)

8'

175

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

1.08

Air

(6)

(3)

12'

175

18

°

36

°

30

°

125

35

°

Forced

4 1/2" Axial

40

3

1.44

Air

(8)

(3)

Rear Storage - Standard Models Only

12” Deep

4'

125

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.45

Air

(1)

(3)

6'

125

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

1.10

Air

(1)

(3)

8'

125

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.9

Air

(2)

(3)

10'

125

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.9

Air

(2)

(3)

12'

125

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.9

Air

(2)

(3)

16” Deep

4'

175

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.45

Air

(1)

(3)

6'

175

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

1.10

Air

(1)

(3)

8'

175

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.9

Air

(2)

(3)

10'

175

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.9

Air

(2)

(3)

12'

175

18

°

36

°

30

°

190

35

°

Forced

5 1/4" x 30

°

40

4

.9

Air

(2)

(3)

NOTES:

These refrigerated merchandisers have been designed for use in stores where temperatures and humidity are maintained at or below 75

°

F and 55%RH. Stores

are responsible for setting their cases appropriately in conditions which vary from the above. The number of defrosts and/or the duration may vary for cases displaying

products for which they were not designed. Italicized data indicates optional equipment.

FOR INQUIRES CALL (909) 590-4910 EXT.133

Electrical and Refrigeration Specifications