Medium Temperature

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

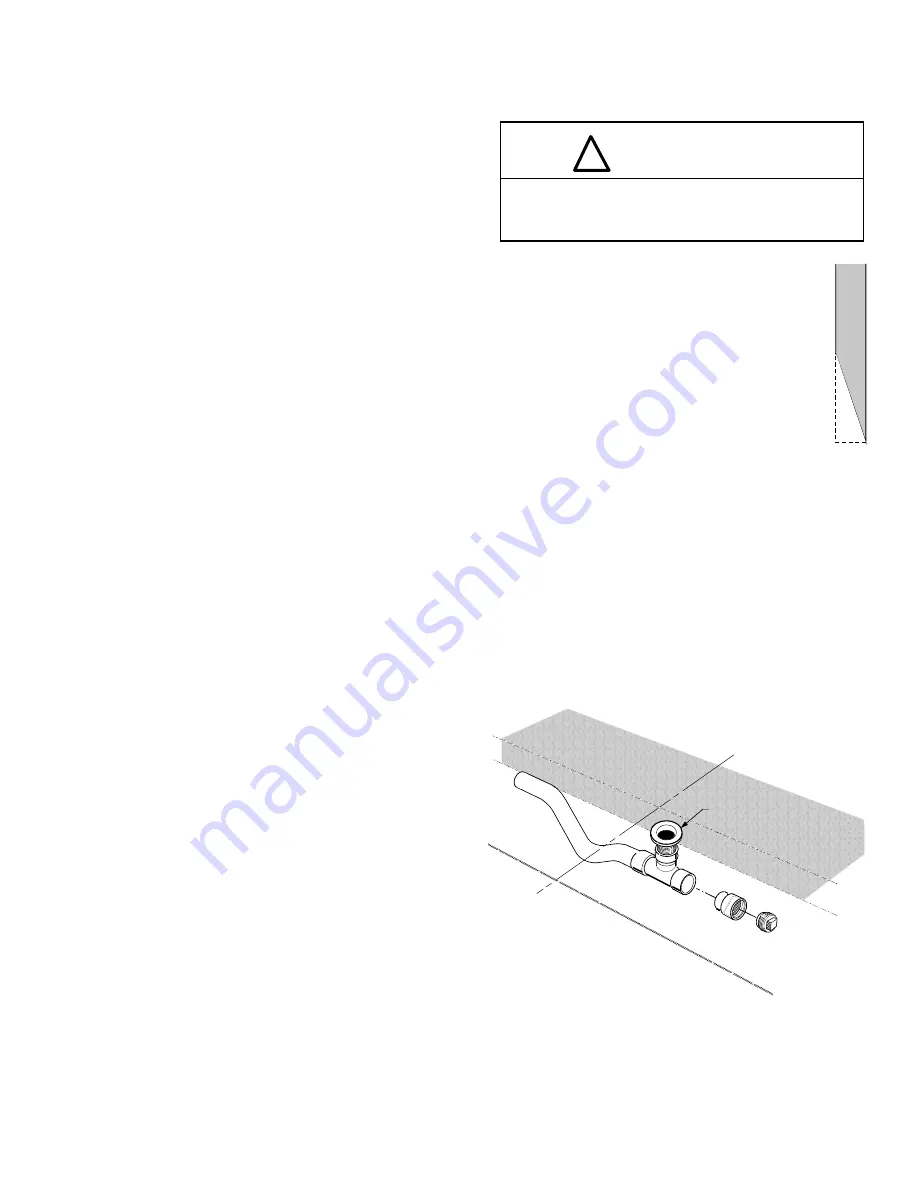

WASTE OUTLET AND WATER SEAL

NOTE:

Water seal outlet must clear front skid rail.

A Tee, adapter, plug and street ell are also supplied

with each merchandiser.

INSTALLING DRIP PIPING

Poorly or improperly installed drip pipes can

seriously interfere with the merchandiser’s opera-

tion and result in costly maintenance and product

losses. Please follow the recommendations listed

below when installing drip pipes to ensure proper

installation.

1. Never use drip piping smaller than the nominal

diameter of the pipe or water seal supplied

with the merchandiser.

2. When connecting drip piping, the “water seal”

must be used as part of the drip piping to

prevent air leakage or insect entrance. Never

use two water seals in series in any one

drip pipe. D

OUBLE WATER SEALS IN SERIES

WILL CAUSE AN AIR LOCK AND PREVENT

DRAINING

.

3. Pitch the drip piping in the direction of flow.

There should be a minimum pitch of

1

/

8

in. per

ft (3 mm per 300 mm).

4. Avoid long runs of drip piping. Long runs

make it impossible to provide the pitch

necessary for good drainage.

5. Provide a suitable air break between

flood rim of the floor drain and outlet

of drip pipe. To meet code on low

base merchandisers, it may be neces-

sary to install a field-supplied drip

pipe reducer. An alternative is to cut

the last section of drip pipe at an

angle.

6. Prevent drip pipes from freezing:

A. Do NOT install drip pipes in contact with

uninsulated suction lines. Suction lines should

be insulated with a nonabsorbent insulation

material.

B. Where drip pipes are located in dead air

spaces, such as between merchandisers or

between a merchandiser and a store wall,

provide means to prevent freezing.

Splashguard brackets MUST be installed

before piping case.

CAUTION

!

DRIP PIPING AND SPLASHGUARDS

Front of Case

Waste Outlet

Field Installed

Water Seal

Base Of Case

Center of Case