Medium Temperature

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 (Printed in U.S.A.)

INSTALLING SPLASHGUARDS

The splashguards are shipped inside each case.

Install splashguard brackets before piping case.

After merchandisers have been leveled and joined,

and all drip piping, electrical and refrigeration

work has been completed, install the splashguards.

To Install splashguards:

1. Check to be sure that all splashguard brackets

are level with the floor. Tighten screws.

2. Align splashguard so that slots in the top of

splashguard match the tabs extending from the

base of the case as shown.

3. Push splashguard up onto tabs until lower edge

of splashguard swings onto bracket. Lower bot-

tom of splashguard onto bracket tabs.

4. Install the front and back splashguards first.

The left and right end angle splashguards have

two pre-drilled flanges on each end. Use one

screw to fasten each flange behind the front

and back splashguards at pre-drilled holes.

5. Install end facet splashguard on brackets; use

four screws in pre-drilled holes to fasten the

end facet splashguard to the left and right end

angle splashguards.

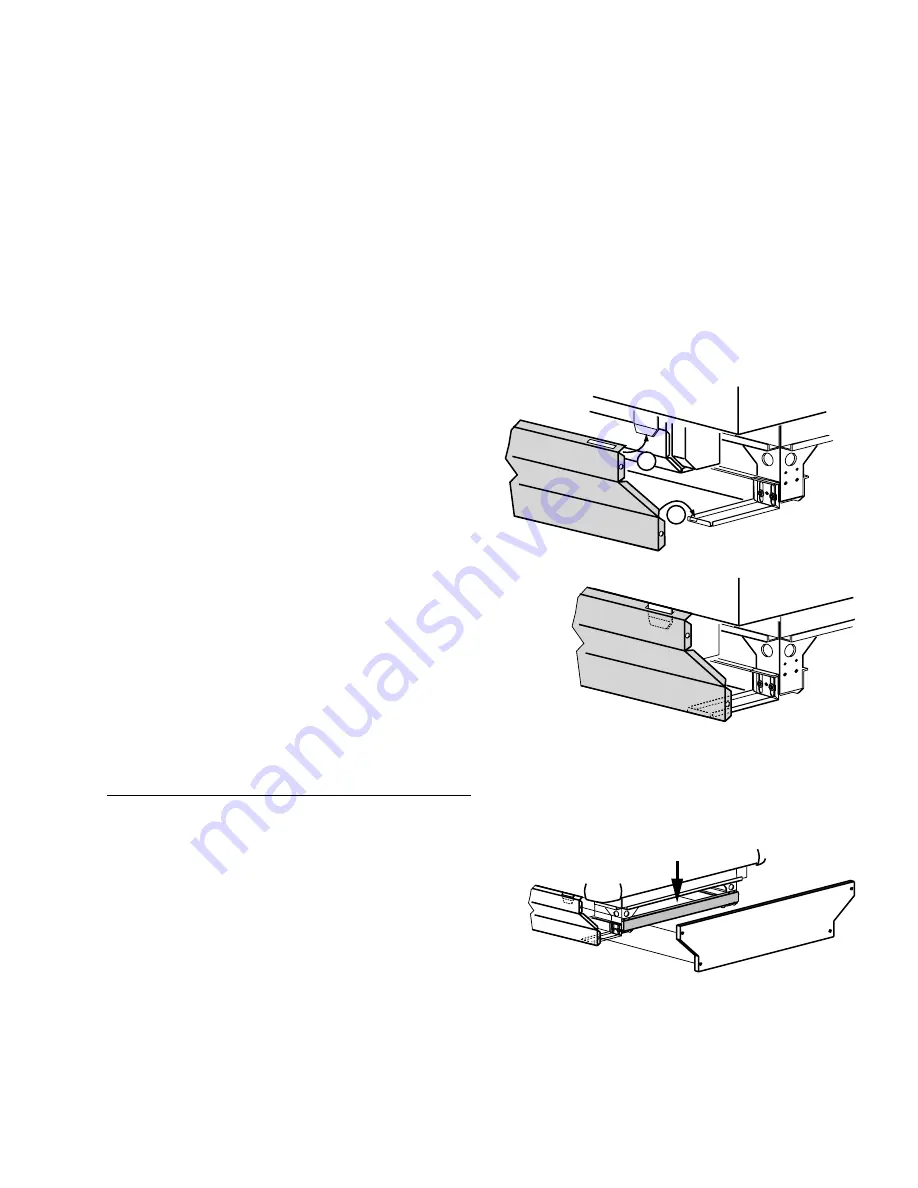

Optional flat end: The flat end splashguard is

installed last, as shown.

END SPLASHGUARD

ATTACHMENT

Attach retainer

before attaching end

1

2