Rev. 0508

7

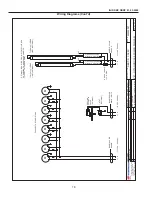

Access to TX valves and Drain Lines

Mechanical -

Remove product from end of case. Remove

product racks. Remove refrigeration and drain access

panels (labeled). TX valve (mechanical only) and drain are

located under each access panel at end of the case.

Electronic -

The Electronic Expansion valve master and

slave cylinder(s) are located within the electrical access

panel(s).

Electronic Expansion valve (Optional)

A wide variety of electronic expansion valves and case

controllers can be utilized. Please refer to EEV and

controller manufacturers information sheet. Sensors for

electronic expansion valves will be installed on the coil inlet,

coil outlet, and in the discharge air. (Some supermarkets

require a 4th sensor in the return air). Case controllers will

be located in the electrical raceway or under the case.

Thermostatic Expansion valve Location

This device is located on the same side as the refrigeration

stub. A balanced port expansion valve model is furnished

as standard equipment, unless otherwise specified by

customer.

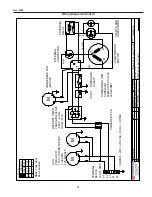

Expansion valve Adjustment

Expansion valves must be adjusted to fully feed the

evaporator. Before attempting any adjustments, make

sure the evaporator is either clear or very lightly covered

with frost, and that the fixture is within 10°F of its expected

operating temperature.

Measuring the Operating Superheat

1. Determine the suction pressure with an accurate

pressure gauge at the evaporator outlet.

. From a refrigerant pressure temperature chart,

determine the saturation temperature at the

observed suction pressure.

3. Measure the temperature of the suction gas at the

thermostatic remote bulb location.

4. Subtract the saturation temperature obtained in step

No. from the temperature measured in step No. 3.

5. The difference is superheat.

6. Set the superheat for 5°F - 7°F.

T-STAT Location

T-STATS are located under access panels on the end of

the case.

Refrigeration (Cont'd)

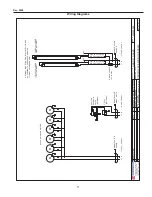

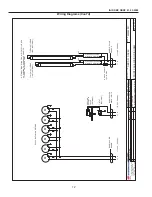

Electrical

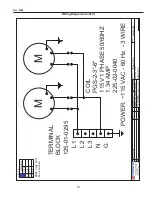

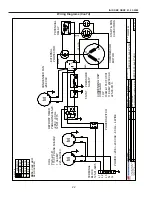

Wiring Color Code

CASE MUST BE GROUNDED

NOTE: Refer to label illustrated above that is affixed to case

to determine the actual configuration as checked in the

“TYPE INSTALLED” boxes.

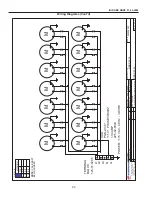

Electrical Circuit Identification

Standard lighting for all models will be full length fluorescent

lamps located within the case at the top.

The switch controlling the lights, the plug provided for

digital scale, and the thermometer are located at the rear

of the case mullion.

The receptacle that is provided on the exterior back of these

models is intended for computerized scales with a five amp

maximum load, not for large motors or other high wattage

appliances. It should be wired to a dedicated circuit.

Electrical Service Receptacles (When Applicable)

The receptacles located on the exterior of the merchandiser

are intended for scales and lighted displays. They are not

intended nor suitable for large motors or other external

appliances.

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters

Thermostats, and Lights.