IGIP-DBP, DBRP 01, 03-0508

8

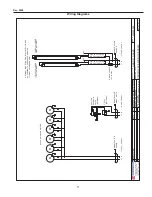

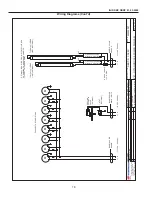

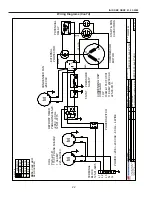

Field Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specified. Field wiring from the refrigeration control panel to

the merchandisers is required for refrigeration thermostats.

Case amperes are listed on the wiring diagram, but always

check the serial plate.

Ballast Location

Ballasts are located within the access panel that runs the

length of the rear of the case. Refer to diagram on page 5.

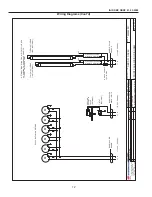

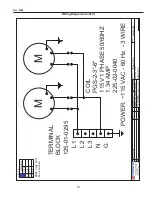

Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes stamped

on the serial plate. Actual ampere draw may be less than

specified. Field wiring from the refrigeration control panel to

the merchandisers is required for refrigeration thermostats.

Case amperes are listed on the wiring diagram, but always

check the serial plate.

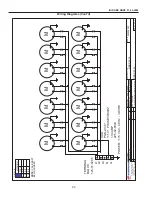

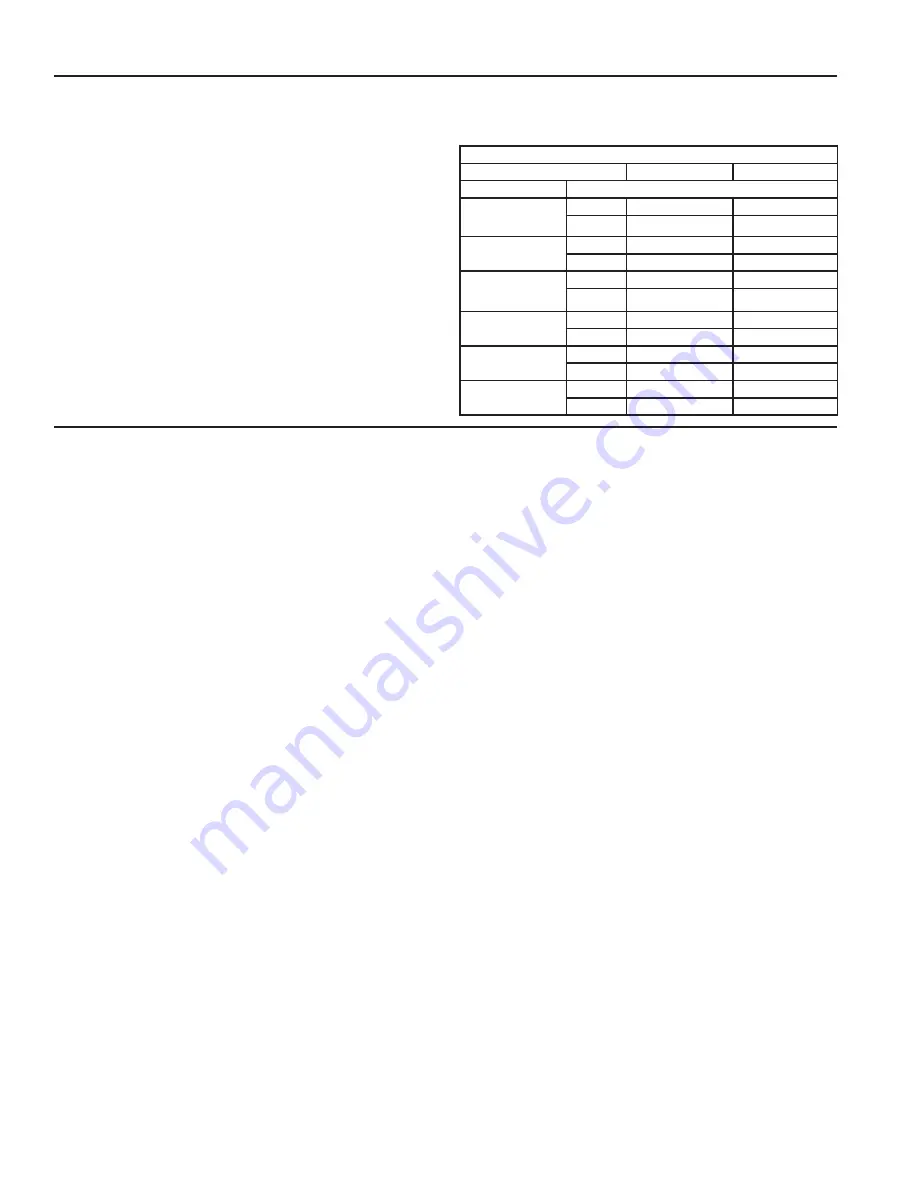

Ashrae Color Code

NOTE: All other manufacturers have no standard sensor codes.

Case Control Systems SENSOR COLOR

Manufacturer ® >

EIL

CPC

Location

Coil Inlet

Color

Blue

Blue

Part#

5-01-1755

5-01-355

Coil Outlet

Color

Red

Red

Part#

5-01-1757

5-01-313

Discharge Air

Color

Green

Green

Part#

5-01-1756

5-01-360

Return Air

Color

Purple

Green

Part#

5-01-1758

5-01-360

Defrost Term. Color

White

Orange

Part#

5-01-0650 5-01-354

Liquid Line

Color

White

Blue

Part#

5-01-0650

5-01-355

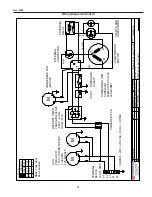

Electrical (Cont'd)

User Information

Stocking

Improper temperature and lighting will cause serious

product loss. Discoloration, dehydration and spoilage

can be controlled with proper use of the equipment and

handling of product. Product temperature should always

be maintained at a constant and proper temperature.

This means that from the time the product is received,

through storage, preparation and display, the temperature

of the product must be controlled to maximize life of the

product. Hussmann cases were not designed to “heat up”

or “cool down” product-but rather to maintain an item’s

proper temperature for maximum shelf life. To achieve the

protection required always:

1. Minimize processing time to avoid damaging

temperature rise to the product. Product should be

at proper temperature.

. Keep the air in and around the case area free

of foreign gasses and fumes or food will rapidly

deteriorate.

3. Maintain the display merchandisers temperature

controls as outlined in the refrigerator section of this

manual.

4. Do not place any product into these refrigerators

until all controls have been adjusted and they

are operating at the proper temperature. Allow

merchandiser to operate a minimum of 6 hours

before stocking with any product.

5. When stocking, never allow the product to extend

beyond the recommended load limit.

Air discharge

and return air flue must be unobstructed at all

times to provide proper refrigeration.

6. There are vents located at the base of the front of the

glass, just above the front rail. These vents supply a

continuous, gentle flow of air across the front glass

which inhibits condensation.

Do not place any

signs or other restrictive objects on the front of

the refrigerator that will block these vents.

7. Avoid the use of supplemental flood or spot lighting.

Display light intensity has been designed for

maximum visibility and product life at the factory.

The use of higher output fluorescent lamps (H.O.

and V.H.O.), will shorten the shelf life of the product.

8. Cold coils remove heat and moisture from the

case and deposit this as frost onto the coil. Thus, a

defrost is required. The only other moisture within

the case is that in the product itself. A single level of

meat will dry out faster than a fully loaded case of

3-4 levels of meat.

Important Steps

1. Do not set temperature too cold, as this causes

product dehydration.

See Case Specs for Proper

Temperature: Settings

.

Case Cleaning

Long life and satisfactory performance of any equipment

are dependent upon the care given to it. To insure long

life, proper sanitation and minimum maintenance costs,

the refrigerator should be thoroughly cleaned frequently.

SHUT OFF FAN DURING CLEANING PROCESS. It can be

unplugged within the case, or shut off case at the source.

The interior bottom may be cleaned with any domestic soap

or detergent based cleaners. Sanitizing solutions will not

harm the interior bottom, however, these solutions should

always be used according to the manufacturer’s directions.

It is essential to establish and regulate cleaning procedures.

This will minimize bacteria causing discoloration which

leads to degraded product appearance and significantly

shortening product shelf life.