Cold Sec on Start up

1. Apply power to the merchandiser.

2. Wait for the self check to complete.

•

During the self check, each LED fl ashes for one second, then

all LEDs turn on for two seconds.

•

If the LEDs do not fl ash, make sure the adjustment knob is

not in the Off posi on.

3. The compressor will start for 30 seconds a er the self check

is complete.

•

The merchandiser temperature displays at startup

•

An ini al defrost occurs two hours a er startup

•

The compressor runs un l it reaches its setpoint tempera-

ture un l defrost.

4. Refrigera on: The compressor will con nue to cycle on-and-

off normal un l defrost occurs.

5. Defrost: Defrost is scheduled to occur every 8 hours, or ear-

lier if triggered by a demand defrost.

•

Defrost con nues for a set me period, or un l the defrost

termina on temperature is reached.

•

During defrost the display shows the ini al defrost tem-

perature (temperature at start of defrost)

•

This ini al defrost temperature is displayed for the set me

period (even if refrigera on mode resumes before the end

of this period).

6. If power is interrupted, the process will start over at step 1.

Opera on

1. DO NOT LOAD PRODUCT un l case reaches desired opera ng

temperature (approx. 4 hrs).

2. Food Product temperature must be below 38°F when loading

a case. Case is not designed to chill food.

3. Check shelf loading. Overstock will reduce case performance

and opera on.

4. DO NOT block discharge or return air. DO NOT display pack-

ages over the air inlet located at the front of the lowest deck.

This restricts airfl ow, and will result in warmer temperature in

the case.

5. DO NOT display more than 150 pounds of product per shelf.

Addi onal weight will damage the shelves.

Temperature Adjustment

See Controller Manual for details

Alarms and codes

See Controller Manual for details

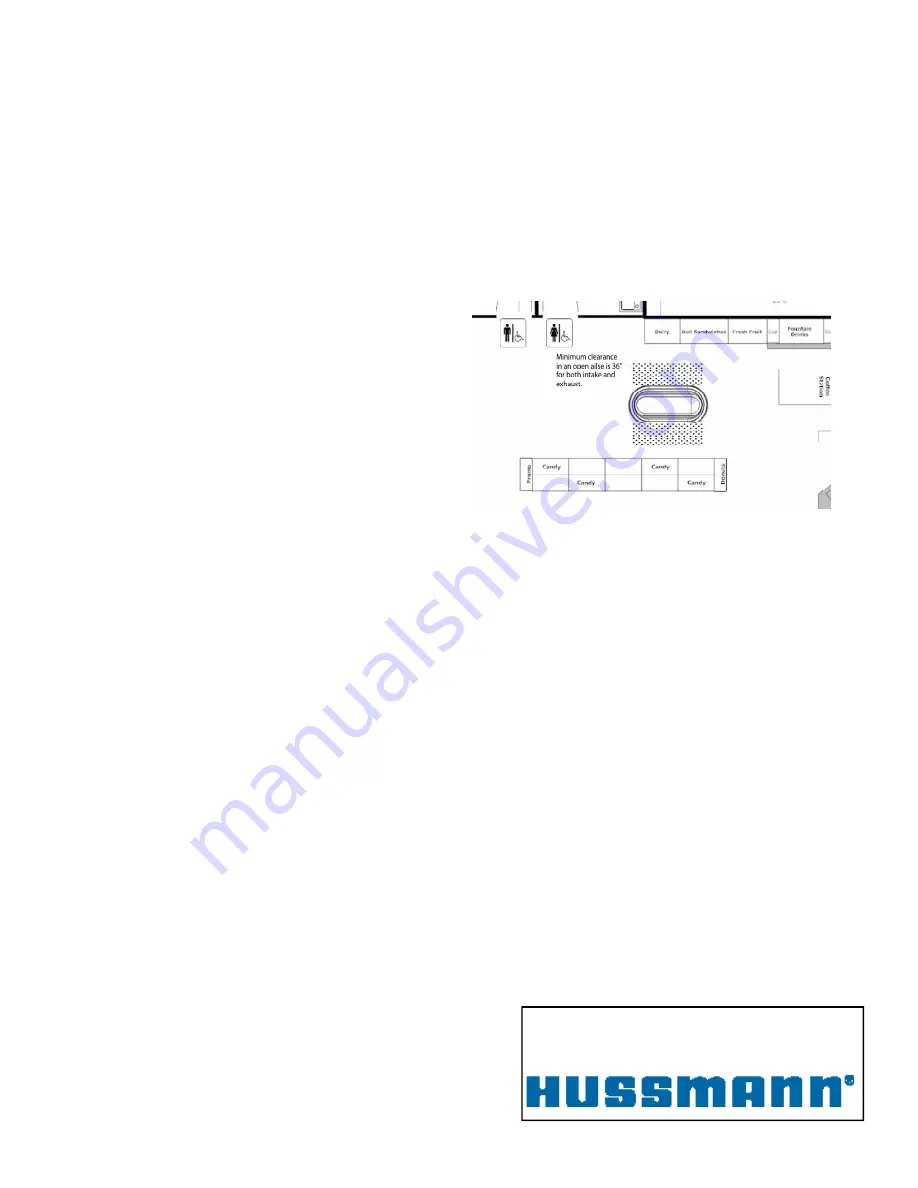

Installa on Store Condi ons

•

Case is designed to operate at temperatures 80°F and or

below 55% rela ve humidity. Case must be kept in that

environment to ensure case performance and product

safety.

For prompt service when contac ng the factory regarding

problems, be sure to have the Case Model and Serial Number

handy. This informa on is on a plate located on itself.

www.hussmann.com (909) 590-4910 (800) 395-9229

Summary of Contents for ENTYCE TY3

Page 3: ...3 Warning...

Page 5: ...5 Entyce Hot Cold Lifting Instructions...

Page 6: ...6 Installation J Bar lift points typical for Cold and Hot section of case...

Page 8: ...8 TY3 4X4E S Cold Section...

Page 12: ...12 15A Wiring Diagram...

Page 13: ......

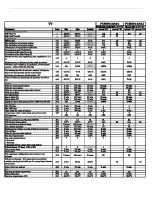

Page 14: ...14 Controller Programmed Parameters...

Page 15: ...15...

Page 19: ...19...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 34: ...34...

Page 35: ...35...

Page 36: ...36...

Page 37: ...37...

Page 38: ...38...

Page 39: ...39...

Page 40: ...40...

Page 41: ...41...

Page 42: ...42...

Page 43: ...43 TY 4X5E H Hot Section...

Page 52: ......