Low Temperature

Excel

P/N 0467434_P

2-1

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

REFRIGERANT

The correct type of refrigerant will be stamped

on each merchandiser’s serial plate. The

merchandiser refrigeration piping is leak

tested, factory sealed and pressurized. Before

making refrigeration hookups, depress the

universal line valve to ensure that coils have

maintained pressure during shipment. When

using high glide refrigerants (e.g., R-407A,

R-448A), if superheat needs to be adjusted,

use the evaporator pressure and subtract the

dew point from the coil outlet refrigerant

temperature to measure the superheat level.

REFRIGERANT PIPING

Connection Location

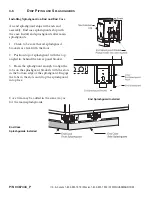

The refrigerant line connections are at the

right- hand end of merchandiser (end opposite

the main serial plate) beneath the display pans.

A sticker marks the location of the connection.

The installer must saw a hole to exit the cases.

A refrigeration shroud ships with each

case. Before making connections, place the

refrigeration shroud over refrigeration piping

so that when the shroud is rotated into place,

it will be in the upright position. The Figure

2-1 shows the correct orientation.

Be careful not to burn, scorch or overheat

the shroud when making connections. Once

connections have been made, apply silicone

sealant to the bottom of the shroud as shown

in Figure 2-2.

REFRIGERATION / ELECTRICAL

Figure 2-2

Refrigerant vapor is hazardous to your health and

can cause death.

Avoid breathing refrigerant and lubrication vapor or

mist. Exposure may irritate eyes, nose and throat.

If accidental system discharge occurs, ventilate

work area before resuming service.

Always wear safety goggles and protective gloves

when working with refrigerants. Contact with

refrigerant may cause injury. Disconnect hoses

with extreme caution! All hoses may contain liquid

refrigerant under pressure.

Be sure that any room where you are working

is thoroughly ventilated, especially if a leak is

suspected.

Read all safety information regarding the safe

handling of refrigerant and refrigerant oil,

including the Material Safety Data Sheet. MSDS

sheets can be obtained from your refrigerant

supplier.

Refrigeration lines are under pressure and

should be depressurized before attempting to

make any connections.

Figure 2-1