Low Temperature

Excel

P/N 0467434_P

3-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

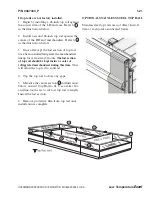

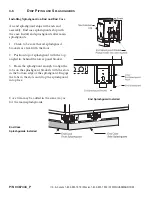

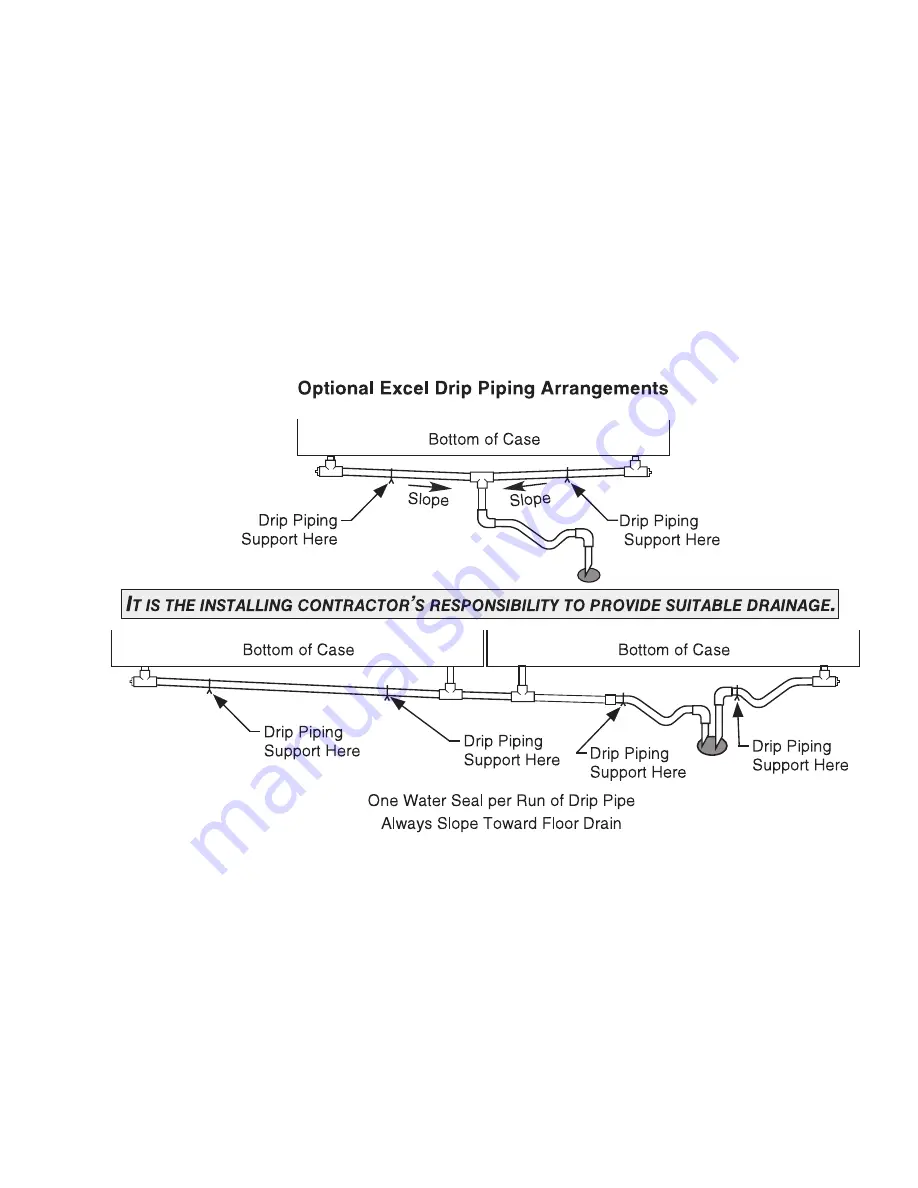

DRIP PIPING LINEUP ARRANGEMENTS

The following illustrations below show typical

arrangements for installing drip pipes for a

lineup of merchandisers. Illustrations are for

reference only. Piping may vary with location

and access to hub drain(s). Each merchandiser

waste outlet must be individually piped to a

hub drain if

1

/

4

in. drip piping pitch cannot be

maintained.

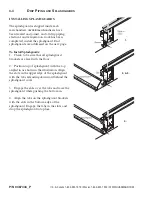

NOTE:

No more than two merchandisers

are to be piped per water seal. Do not install

water seal between two merchandiser waste

outlets that are piped together.

(Double water

seals in series will cause an air lock and prevent

drainage.)