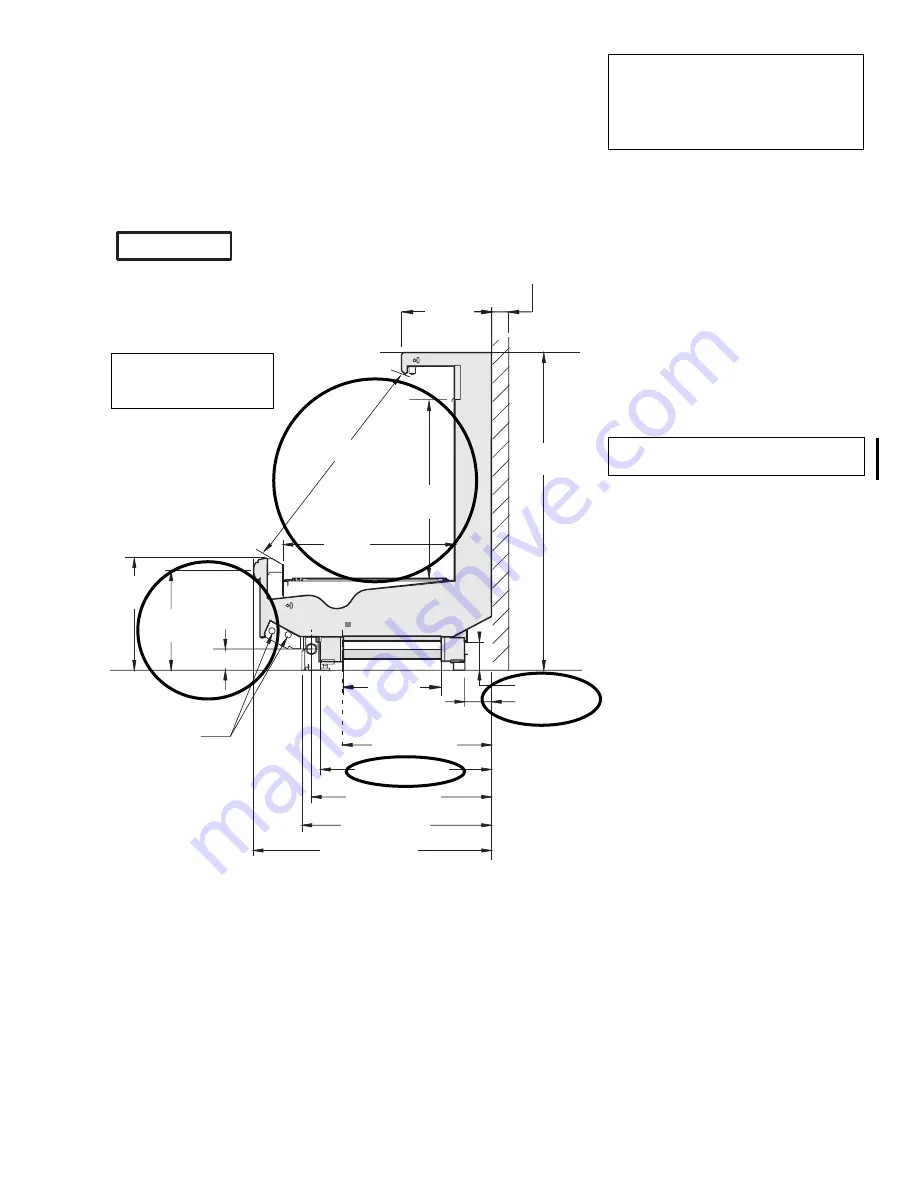

Dimensions shown as inches and (mm).

P/N 0466005_H

3 of 10

55

3

/

4

(1415)

31

5

/

8

(804)

4

3

/

4

(120)

30

1

/

4

(768)

42

(1064)

33

1

/

2

(851)

26

1

/

4

(665)

C2X-XLEP

30

1

/

4

(768)

15

7

/

8

(403)

FAN

C

O

I

L

17

1

/

4

(438)

3 In.

(77 mm)

Required

Air Gap

19

5

/

8

(500)

4

7

/

8

(123)

Electrical

Case to Case

Connections

17

1

/

8

(436)

Refrigeration

Outlet

3

5

/

8

(92)

39

5

/

8

(1006)

31

1

/

4

(793)

REFRIGERATION DATA

Note:

This data is based on store temperature and

humidity that does not exceed 75°F and 55% R.H.

C2X-XLEP

Dairy/Deli/Produce†

U

NLIT

L

IT

Discharge Air °F

33

31

Evaporator °F

28

26

Unit Sizing °F

26

24

†For red meat application, lower evaporator

temperature and unit sizing 3ºF, increase Btu 5%.

Btu/hr/ft — Unlit Shelves

C2X-XLEP

‡‡

Parallel

Conventional

U

NLIT

900

960

‡‡ Add 10 Btu/hr/ft

per shelf row

for LED fixtures.

Add 20 Btu/hr/ft

per shelf row

for fluorescent lamps.

DEFROST DATA

C2X-XLEP

Frequency (hr)

8

Defrost Water (lb/ft/day)

7

(±15% based on case configuration and

product loading.

O

FFTIME

C2X-XLEP

Time (minutes)

30

E

LECTRIC OR

G

AS

Not Recommended

CONVENTIONAL CONTROLS

Low Pressure Backup Control

C2X-XLEP

Dairy/Deli/Produce

††

CI/CO*

19

°

F / 9

°

F

Indoor Unit Only, Pressure Defrost

Termination*

48

°

F

*Use a Temperature Pressure Chart to determine

PSIG conversions.

††

For red meat application, reduce low pressure

backup control by 3

°

F.

Estimated Charge (lbs)** C2X-XLEP

4 ft

1.6

6 ft

2.3

8 ft

3.2

12 ft

4.5

**This is an average for all refrigerant types.

Actual refrigerant charge may vary by

approximately half a pound.

Impact

Excel

C2X-XLEP

Dairy/Delicatessen

Precut & Packaged Produce

Multi-deck, 4 Display Levels, Low Front, 55 In. Back

NSF Certification

This merchandiser model is manufactured to meet ANSI/NSF

(National Sanitation Foundation) Standard #7 requirements for

construction, materials & cleanability.

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A. • WWW.HUSSMANN.COM

See Page 9 for

shelf arrangement.