Hussmann Corporation • Bridgeton, Missouri 63044-2483 U.S.A.

Innovator Door Installation and Service Instruction

P/N 0425683_M

9

6. Rock the door out and pull the bottom hinge pin

out from the bottom socket.

7. Install the new door in reverse order.

8. Adjust the torque on the new door. If needed,

adjust sag.

INNOVATOR DOOR HINGE

REPLACEMENT

The following provides supplemental information for

the replacement of a worn hinge pin. In addition to the

hinge pin, it is recommend that the following parts be

replaced.

*Note: If a hinge pin is bent or worn because of

improper shimming, the addition of a nylon spacer

(item 7), attached to the door’s torque rod, may be

required.

In order to address a worn hinge pin, it is necessary to

remove the door from the frame.

Note: The new hinge pin supplied with this replace-

ment kit is longer than the existing hinge pin. These

were designed to be backward compatible.

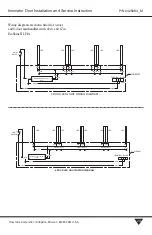

Tips for replacing the hinge pin and related components:

• Always replace components 1 through 6.

• Torque all retaining screws to 100 in-lbs.

• After removing the pin and spring, clean out any

debris (nylon or metal shavings) that may

be remaining in the door’s “hinge pin /spring” socket.

• Make sure the hinge pin bushing (4551267) is

installed onto the hinge pin (0453783)

• If the hinge pin is bent, it’s because the pin is rotat-

ing on its shaft instead of the top bell. This is most

likely caused by improper shimming. To correct the

issue, order the torque rod spacer (item 7) along with parts

1 through 6.

REPLACING MAGNETIC GASKET

Carefully remove the old gasket from the groove in the

back of the door, Figure 9.

The new gasket will be easier to work with if it is at

ambient temperature. Begin by lubricating the new

gasket with a mild soap and water solution.

Gasket

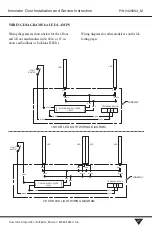

1. Top Hinge Plate

0543783

2. Top Hinge Plate Bushing

4551267

3. Top Hinge Spring (long)

1900391

4. Top Hinge Plate Socket (black)

4550103

5. Top Hinge Plate Socket (silver)

4550103

6. Torque Rod Spacer (*see note)

4551465

7. Socket Retainer Screw

0539743