©2009 HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

U.S. & CANADA 1-800-922-1919 • MEXICO 1-800-522-1900 • WWW.HUSSMANN.COM

TROUBLESHOOTING

The following chart identifies most common

problems, their causes, and suggested solutions.

15

P/N 0512888_A

01 October 2009

MAXI-140

Hussmann Beer Merchandiser

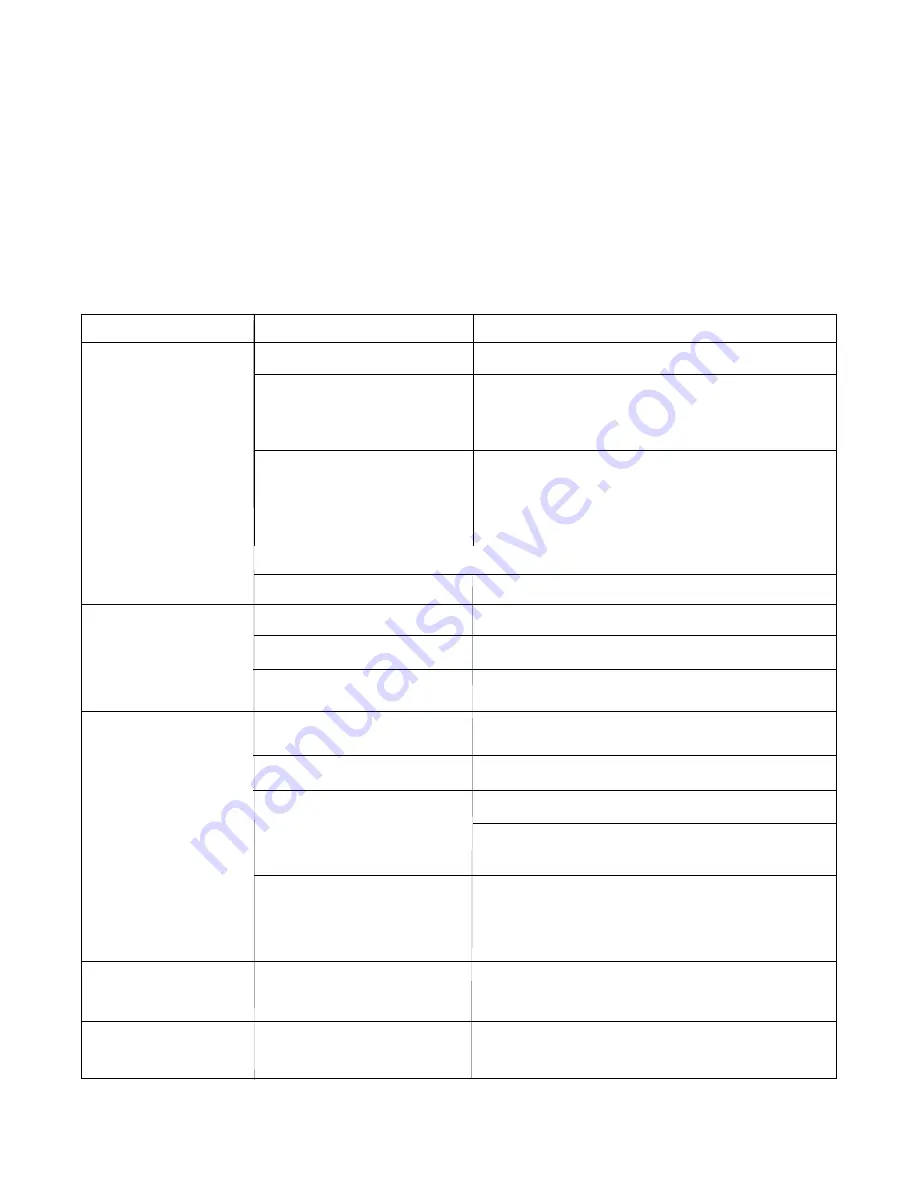

Problem

Possible Causes

Solution/Action

Does not turn on

Plug is out of outlet

Insert plug into outlet

Poor contact at outlet

Remove and reinsert plug into outlet.

If good contact cannot be established,

contact a licensed electrician to replace the outlet.

No power

Power outage OR

Circuit breaker tripped

UNPLUG UNIT until power is restored

UNPLUG UNIT until breaker is reset

Low Voltage

Install a voltage regulator

Unusual Noise

Unit not level

Reposition and level the unit

Unit contacting structure

Reposition unit to provide space on all sides

Rear grille loose

Fasten grille to attenuate sound

Slow to cool

Dirty condenser coil

Clean condenser coil

product

Poor airflow around unit

Reposition unit to provide space on all sides

Evaporator blocked by ice

Verify that door is sealing completely

Heavy use in high humidity -- reset Safe-NET

controller to make defrosts more frequent

Loading with warm product

The warmer the product when placed in the Hussman

Beer Merchandiser, the longer the time needed to

cool the product.

Temperature display

Recently stocked

Allow time for temperature display to catch up

not accurate

with stocking -- about 30 minutes.

Condensation

High relative humidity

Remove moisture with soft cloth. Reduce ambient

on door

humidity. Move unit to area of lower humidity.

Troubleshooting Guide

To place a service call, please phone Hussmann’s Call Center

U.S. or Canada 1-800-922-1919 • Mexico 1-800-522-1900. .

Summary of Contents for MAXI-

Page 20: ......