P/N 0515388_L

1-11

Medium Temperature

Excel

with

EcoVision II Doors

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

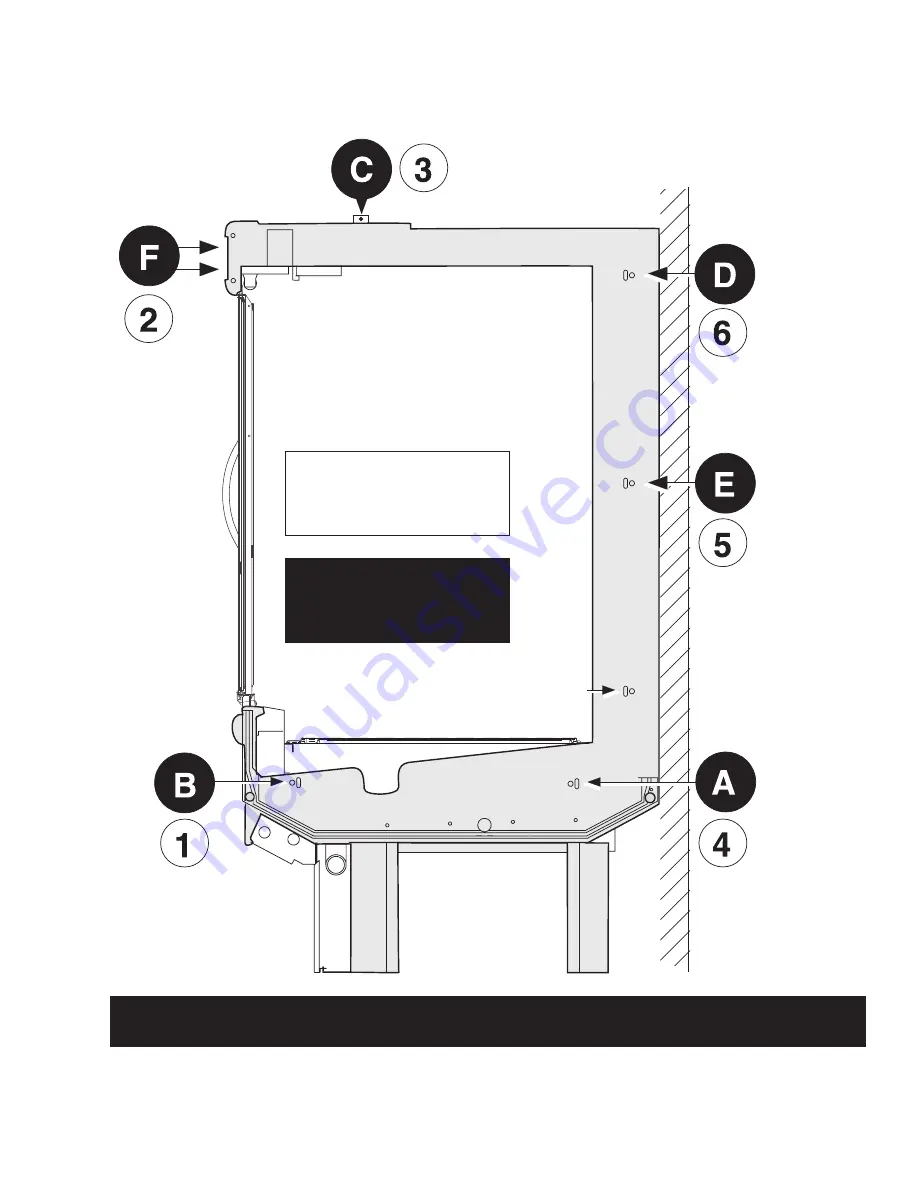

1

1

/

4

in.

Cap Screw

1

1

/

4

in.

Cap Screw

1

1

/

4

in.

Cap Screw

3

1

/

2

in.

Cap Screw

3

1

/

2

in.

Cap Screw

Use

Neoprene

Washers

Here

Use

Neoprene

Washers

Here

Do not use for joining

Remove clip if installed

Alignment order

1, 2, 3, 4, 5, 6

Tightening order

A, B, C, D, E, F

Tighten in Order Shown