P/N 0515388_L

2-3

HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

Medium Temperature

Excel

with

EcoVision II Doors

INSULATION

Additional insulation for the balance of the

liquid and suction lines is recommended

wherever condensation drippage is objection-

able or lines are exposed to ambient conditions.

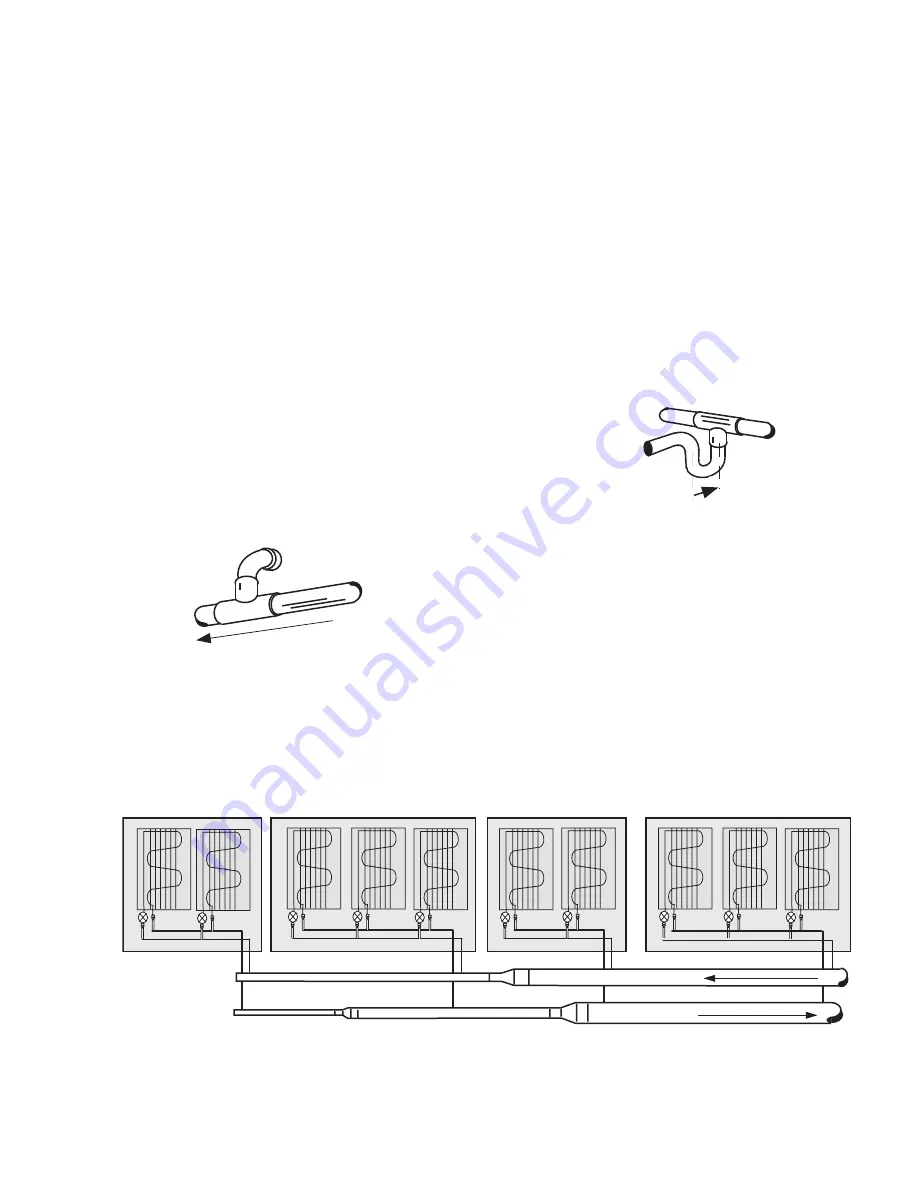

SUCTION LINE

• Pitch in direction of flow.

• May be reduced by one size at one third of

merchandiser run load and again after the

second third. Do not reduce below the

merchandiser suction line size.

• Merchandiser suction lines should enter at

the top of the branch line.

LIQUID LINE

• May be reduced by one size after one half

the merchandiser run load. Do not reduce

below the merchandiser liquid line connec-

tion size.

• Take-offs to merchandiser liquid lines

should exit the bottom of the branch liq-

uid line. Provide an expansion loop for

each evaporator take-off (minimum 3 in.

[76 mm] loop).

Suction Line Return

Offtime Defrost

8 Ft Case

(2438 mm)

12 Ft Case

(3658 mm)

8 Ft Case

(2438 mm)

12 Ft Case

(3658 mm)

Liquid Line

Suction Line

Liquid Line Take Off

Minimum Loop

3-in. (76 mm)