20

Electrical

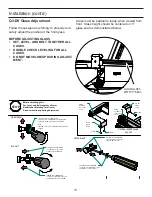

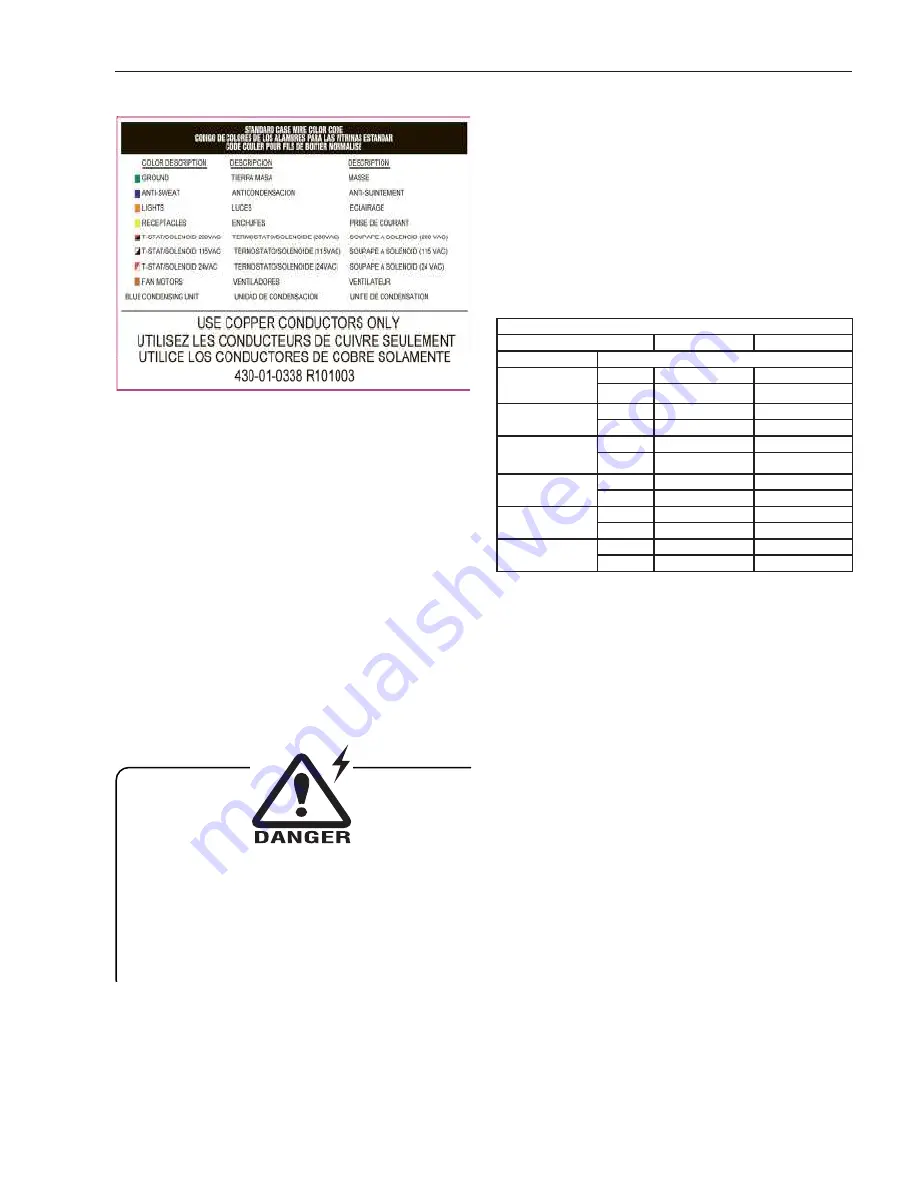

Wiring Color Code

CASE MUST BE GROUNDED

NOTE:

Refer to label affi xed to case to determine the actual

confi guration as checked in the “TYPE INSTALLED”

boxes.

Electrical Circuit Identifi cation

Standard lighting for all models will be full length fl uorescent

lamps located within the case at the top. The switch

controlling the lights, the plug provided for digital scale, and

the thermometer are located at the rear of the case mullion.

The receptacle that is provided on the exterior back of these

models is intended for computerized scales with a fi ve amp

maximum load, not for large motors or other high wattage

appliances. It should be wired to a dedicated circuit.

NOTE: The total case electrical draw must not exceed 30 Amps

ampacity at 115V in one connected lineup.

Electrical Service Receptacles (When Applicable)

The receptacles located on the exterior of the merchandiser

are intended for scales and lighted displays. They are not

intended nor suitable for large motors or other external

appliances.

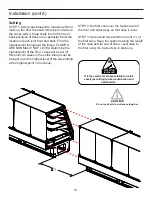

BEFORE SERVICING

ALWAYS DISCONNECT ELECTRICAL

POWER AT THE MAIN DISCONNECT

WHEN SERVICING OR REPLACING ANY

ELECTRICAL COMPONENT.

This includes (but not limited to) Fans, Heaters

Thermostats, and Lights

.

Field Wiring and Serial Plate Amperage

Field Wiring must be sized for component amperes printed

on the serial plate. Actual ampere draw may be less than

specifi ed. Field wiring from the refrigeration control panel to

the merchandisers is required for refrigeration thermostats.

Case amperes are listed on the wiring diagram, but always

check the serial plate.

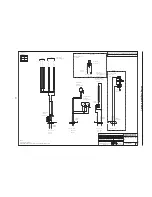

LED Driver Location

Drivers are located within the access panel that runs the

length of the rear of the case.

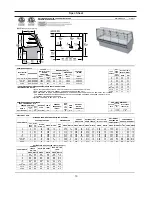

Ashrae Color Code

NOTE: All other manufacturers have no standard sensor codes.

Case Control Systems SENSOR COLOR

Manufacturer ® >

EIL

CPC

Location

Coil Inlet

Color

Blue

Blue

Part#

225-01-1755

225-01-3255

Coil Outlet

Color

Red

Red

Part#

225-01-1757

225-01-3123

Discharge Air

Color

Green

Green

Part#

225-01-1756

225-01-3260

Return Air

Color

Purple

Green

Part#

225-01-1758

225-01-3260

Defrost Term.

Color

White

Orange

Part#

225-01-0650

225-01-3254

Liquid Line

Color

White

Blue

Part#

225-01-0650

225-01-3255