15

Installation (cont’d)

Setting and Joining

The sectional construction of these models en-

able them to be joined in line to give the effect of

one continuous display.

An Alignment pin kit is supplied with every case

and must be used in alignment.

Leveling

IMPORTANT! IT IS IMPERATIVE THAT CASES

BE LEVELED FROM FRONT TO BACK AND

SIDE TO SIDE PRIOR TO JOINING. A LEVEL

CASE IS NECESSARY TO INSURE PROPER

OPERATION, WATER DRAINAGE, GLASS

ALIGNMENT AND OPERATION OF THE HING-

ES SUPPORTING THE GLASS. LEVELING

THE CASE CORRECTLY WILL SOLVE MOST

HINGE OPERATION PROBLEMS.

1. Using case blueprints, measure off and mark

on the floor the exact dimensions of where the

cases will sit. Snap chalk line for front and back

positions of base rail or pedestal. Mark the loca-

tion of each joint front and back. Find the high-

est point throughout the lineup. FLOORS ARE

NORMALLY NOT LEVEL! Determine the highest

point of the floor; cases will be set off this point.

All cases in the entire lineup must be brought up

to the highest level of the case sitting at the high-

est point in the lineup.

2. Set first case over the highest part of the floor

and adjust base so that case is level by using

shims.

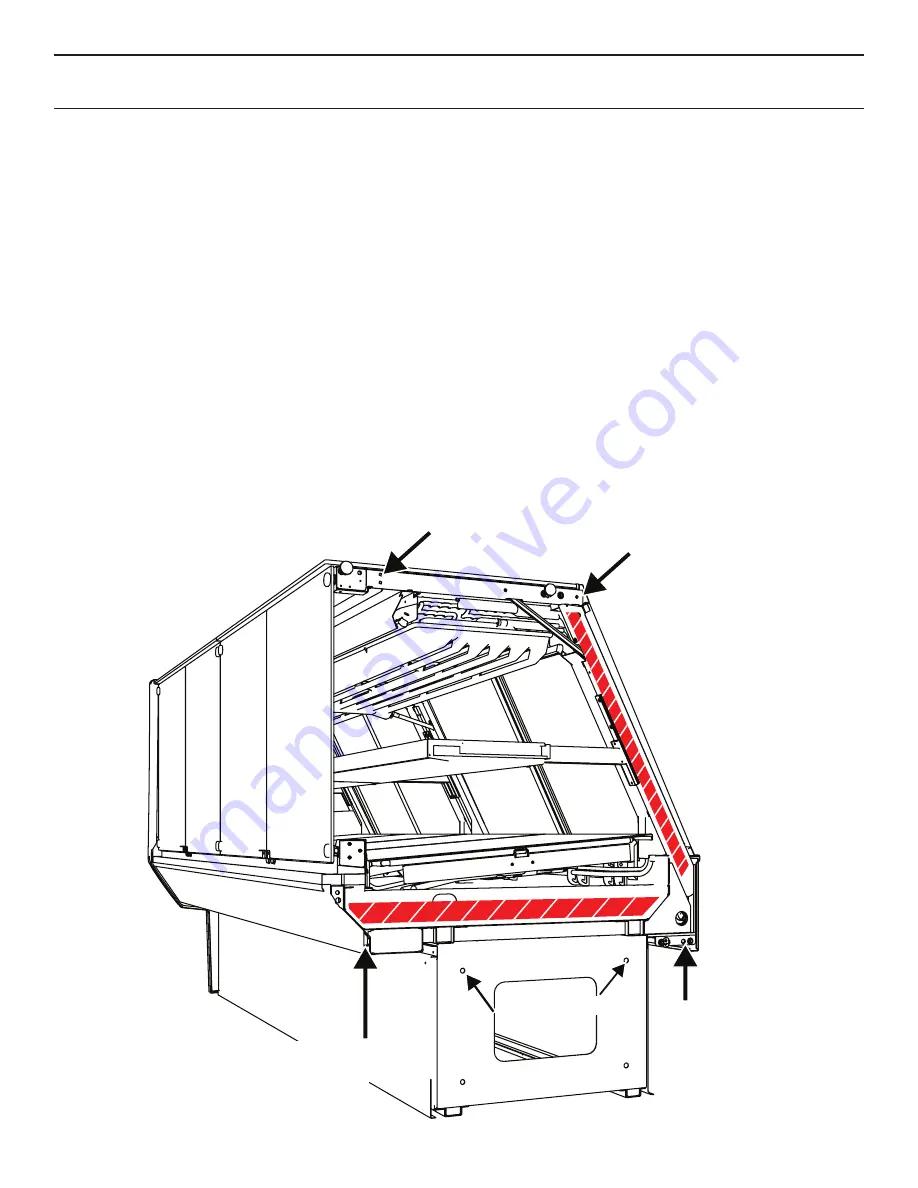

ALIGNMENT

PLEXI PLATE

ALIGNMENT PIN

LOCATION

CASE BOLTING

LOCATION

CASE BOLTING

LOCATION

ALIGNMENT

PIN