6

SHVSV Lifting and Transport

Instructions

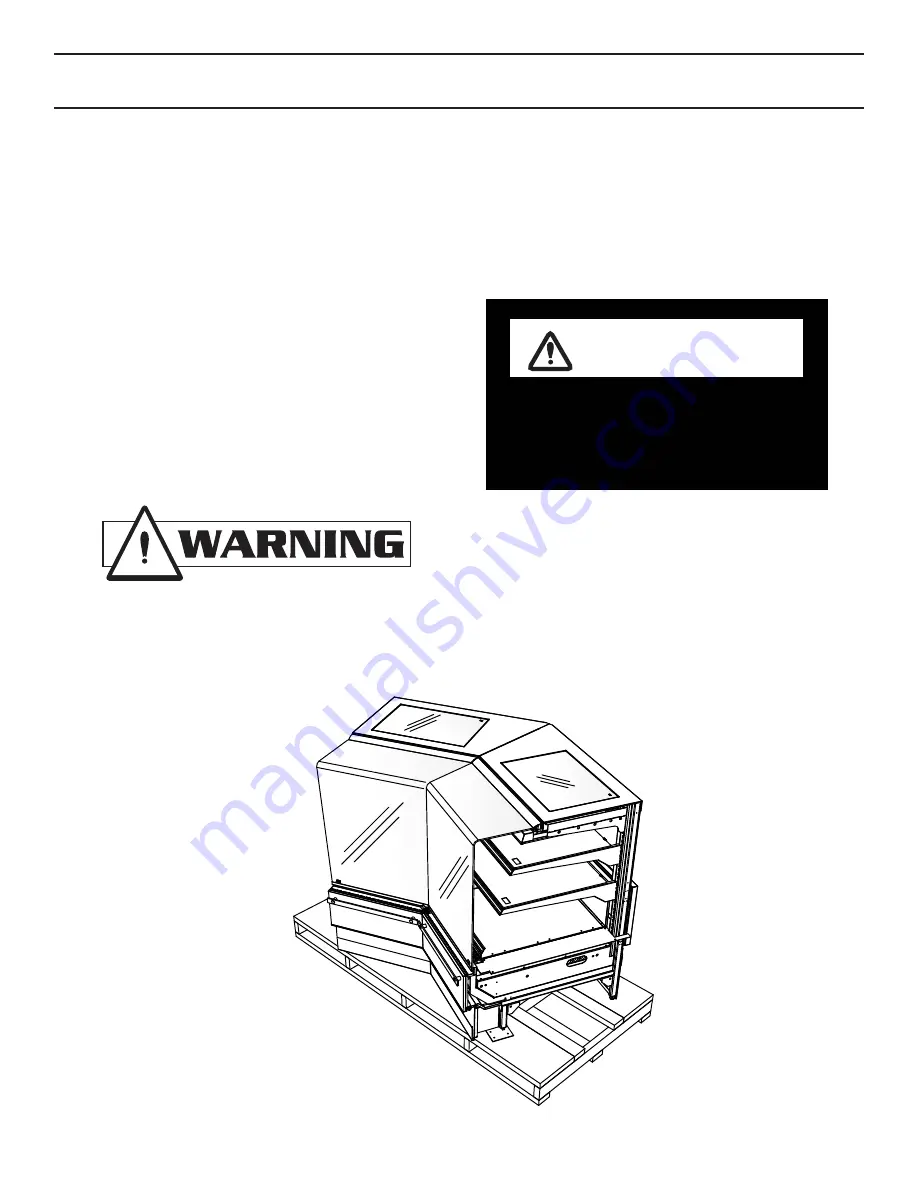

1. The SHVSV can be lifted by a forklift using the skid

which the merchandiser is mounted to.

2. Move the fi xture as close as possible to its per-

manent location and then remove all packaging.

Check for damage before discarding packaging.

Remove all separately packed accessories such

as kits and shelves.

3. Make sure that fork spacing and width will not

damage drain or come in contact with piping, or

electrical lines

4. Be sure that the forks are long enough to sup-

port beyond the center of the case but not dam-

age near components. Check for proper balance

before moving. A minimum fork length of 36” is

recommended for 68” wide cases

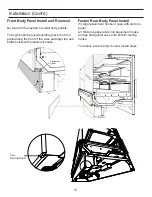

Installation (Cont’d)

5. The SHVSV merchandiser can be raised at one

end underneath the deck with a forklift or J-Bar if

forklift is not accesible to allow the placement of

rollers or dollies.

6. Evenly support the entire base structure on rollers

or dollies before attempting to move. Each Base

Leg must have its own dollie to properly support

the case.

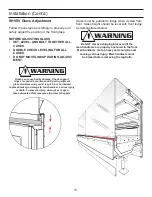

WARNING

Improper placement of forks may damage

drainage piping. Use a spotter when placing

forks. Make sure that piping will not be dam-

aged. Use J-Bars or Jacks if forks cannot be

used safely

Lifting Points are typical and dependent upon size of

case and refrigeration application, drainage confi gu-

rations will call for altercations in Lifting Zones.

Do NOT remove shipping braces until the

merchandisers are properly anchored to the floor.

Merchandisers are top heavy and could tip over

causing serious injury. Merchandisers must

be braced before removing the lag bolts.

Summary of Contents for SHVSV Series

Page 9: ...9 Joint Trim Pack list ...

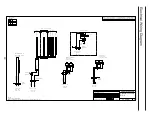

Page 20: ...20 Electrical Wiring Diagram 0 0 0 1 0 0 0 0 2 0 0 3 0 0 1 1 1 1 1 ...

Page 21: ...21 Electrical Wiring Diagram Cont d 0 1 1 1 2 0 1 1 0 1 1 3 0 1 1 4 0 1 1 2 2 2 2 ...

Page 24: ...24 0 1 1 1 2 0 1 1 0 1 1 2 3 0 1 1 4 0 1 1 2 2 2 2 2 2 2 2 Electrical Wiring Diagram Cont d ...